Results 3,571 to 3,580 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

10-14-2016, 11:12 PM #3571Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

It is not the same issue....

Thought I posted about that, maybe not though. Last time it turned out that I replaced the driver with another blown driver that got mixed in with my spares. But that don't happen any more lol.

Def not whats going on this time. Seeing this on both extruders.

Off-topic a bit...

That fella still doing the nozzle packs on Amazon for good price? I tried to search but could not find em.

-

10-14-2016, 11:16 PM #3572Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

230c is my typical ABS temp.

I live in south Texas man, right on the coast. My numbers are usually a little bit of the 'norms' that most are using. It's because its SO damn humid here.....70% humidity is a dry day for these parts.

Hurts more than 3d printing too. I have been a metal worker most of my life, and professionally till my last knee surgery. This is the land of metal death....you leave bare metal over night and it will be rusted to hell the next morning. Only takes about 2 weeks for steel to get pitted around here.

-

10-14-2016, 11:43 PM #3573Editor in Chief

Bitsonline

Tips Appreciated But Not Expected

BTC: 16wxHvKd3oU6SVjv6FrenqhkvRmc8t7sPy

DASH: XqyaWxH896j9YeV1M35Gzb5gmRPmPbNDGq

-

10-15-2016, 12:38 PM #3574Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

-

10-15-2016, 01:24 PM #3575Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

-

10-15-2016, 03:24 PM #3576Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 902

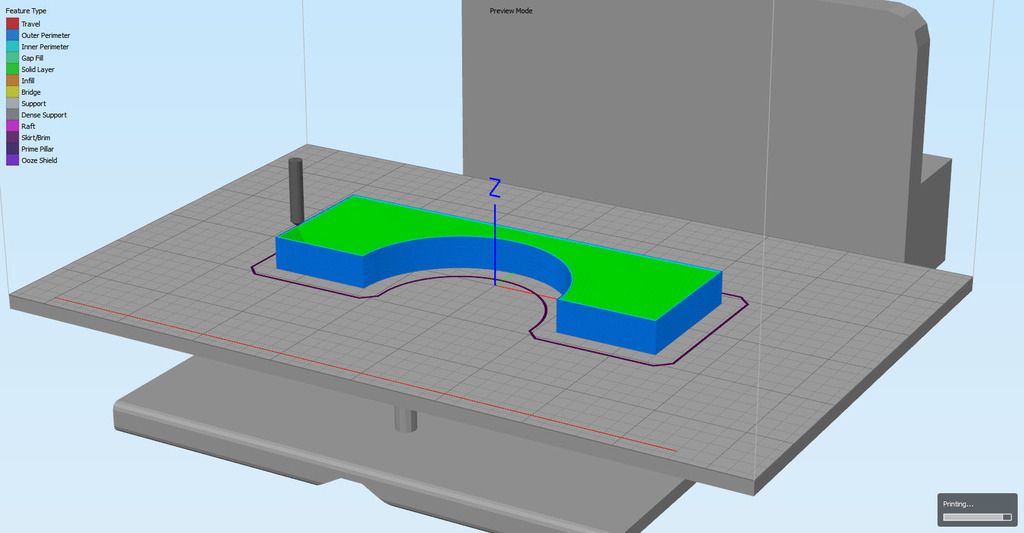

Hey guys,

I am making pipe saddle clamps. Basically I have to clamp a 1" pole to a 2 1/2" pole so I am making sets of these to clamp around each pole and then they will hook together.

My question is this: Do you think PLA will be fine outside or should I go with ABS? It will have direct sunlight, and big temp swings from summer to winter. I don't care what it looks like but that it holds up for a reasonable amount of time.

[IMG] [/IMG]

[/IMG]

-

10-15-2016, 04:40 PM #3577Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

-

10-15-2016, 05:42 PM #3578Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

The feeders are still at default, what is 127 iirc.

Found the culprit, was the feed carriage. DO NOT print feed carriages from ABS!!!

Still not exactly sure what happened, but seems like the spring was no longer able to put enough tension on the floating arm. Spring is still as springy as the day it was new so has to be the carriage.

Back to the stock carriage, and its printing, finishing prints...still having some serious extrusion issues. Will post a pic of whats going on now in a bit...gotta get dinner going for the kids right now lol.

-

10-15-2016, 06:16 PM #3579Editor in Chief

Bitsonline

Tips Appreciated But Not Expected

BTC: 16wxHvKd3oU6SVjv6FrenqhkvRmc8t7sPy

DASH: XqyaWxH896j9YeV1M35Gzb5gmRPmPbNDGq

-

10-15-2016, 06:18 PM #3580Editor in Chief

Bitsonline

Tips Appreciated But Not Expected

BTC: 16wxHvKd3oU6SVjv6FrenqhkvRmc8t7sPy

DASH: XqyaWxH896j9YeV1M35Gzb5gmRPmPbNDGq

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help