Results 111 to 120 of 476

Thread: Itty Bitty Double Extruder

-

12-12-2014, 08:22 PM #111

Got my deburring tool today. It's really nice and is so much better than the back side of an xacto.

Last edited by RobH2; 12-13-2014 at 01:36 PM.

Bambu P1S/AMS

NVision4D http://nvision4d.com

-

12-13-2014, 01:20 PM #112Technologist

- Join Date

- Nov 2014

- Location

- Orange, CA

- Posts

- 78

-

12-13-2014, 08:58 PM #113

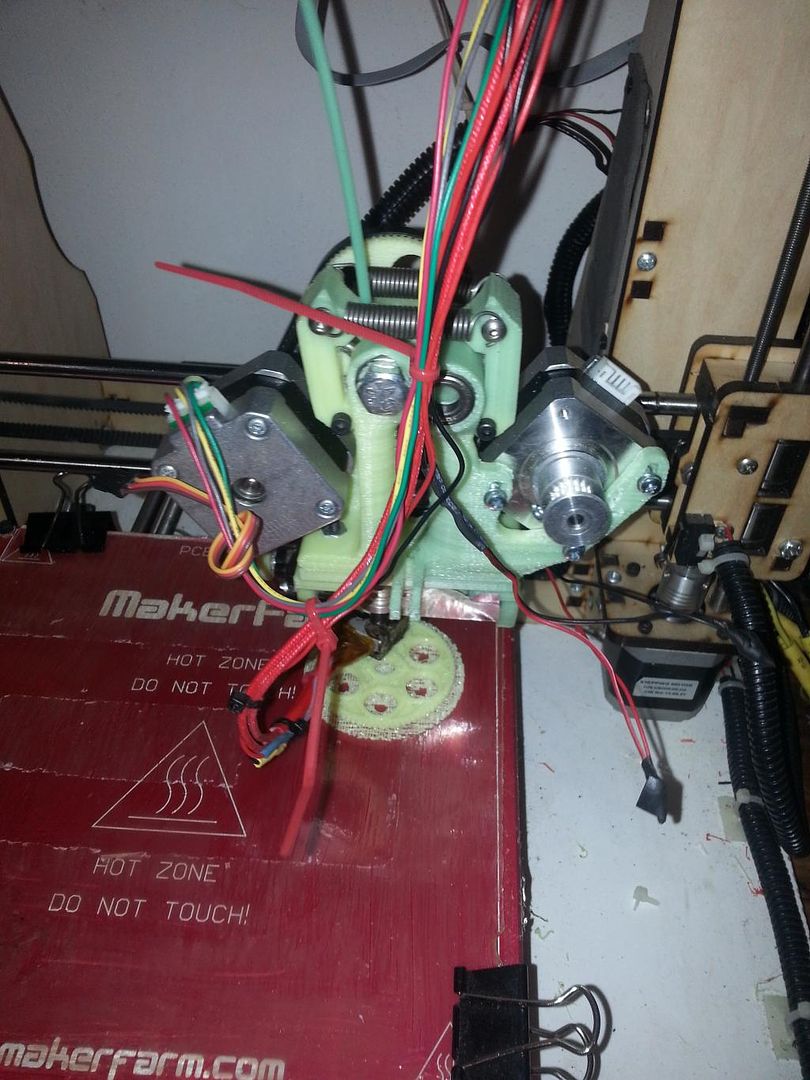

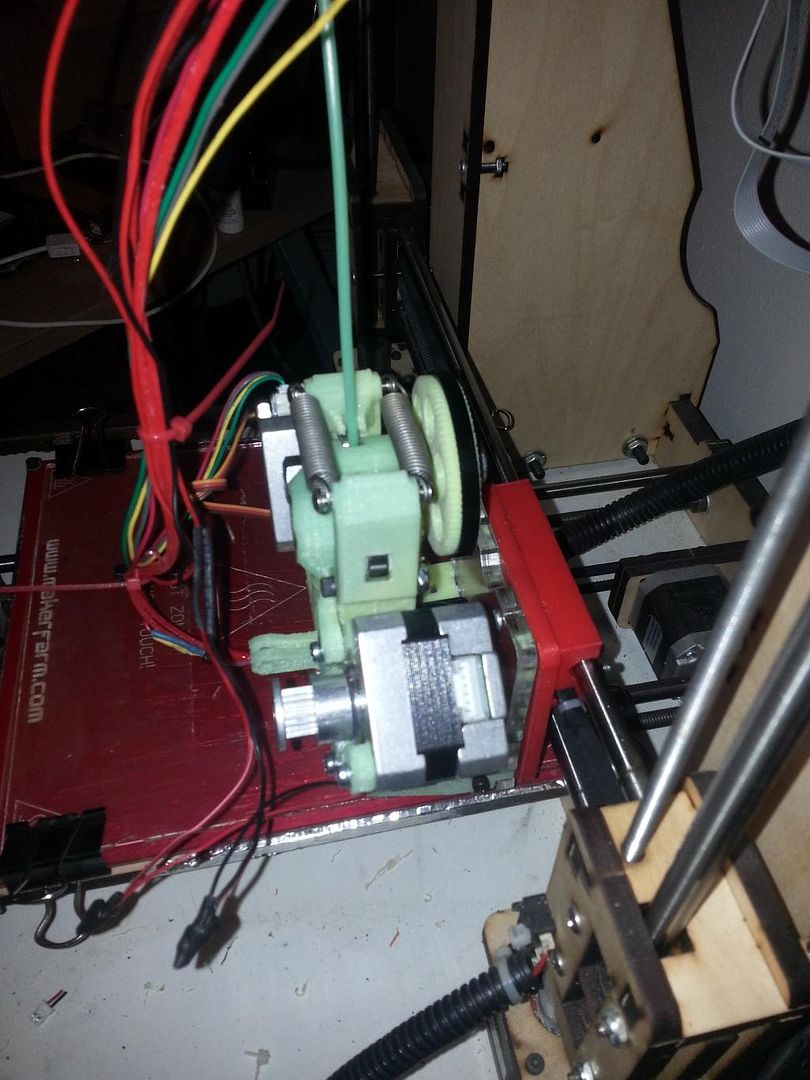

First print with the Itty Bitty Nema17 Modified Magma hot Ends. . We are only using one drive as someone ordered the wrong hobbed bolts (That would be me). So far its printing nice without any setting changes. Very happy with the fit form and function thanks RobH for the 17 model and Clough for the design. still need to tidy up the wires and get the auto bed level working.

-

12-13-2014, 09:52 PM #114

Really good to hear. So the main body rebuild was good? Any tolerance issues?

Bambu P1S/AMS

NVision4D http://nvision4d.com

-

12-13-2014, 09:57 PM #115

Just discovered and issue when the motor mounts heat up the attach points sag causing the belt to loose tension. It will need to be reinforced.

-

12-13-2014, 10:34 PM #116

Tell me what you think will fix it. Maybe a plate with 4 holes and a center hole for for the pulley? I can put a hole in the middle for it to stick through. Maybe the arms are a bit thicker? Tell me what you need and I'll modify it.

Bambu P1S/AMS

NVision4D http://nvision4d.com

-

12-14-2014, 12:25 AM #117

This is not the prettiest model but it might do the trick. If so, I'll make it nicer later. I know it's a long print but if you think this will do it give it a go.

It must warp a alot because the best part about 'clough42' using belts is that they don't skip unless they get really loose. Are you pushing too many amps through the motors maybe? Mine don't run very hot.

Nema17_Versions.jpgLast edited by RobH2; 12-14-2014 at 10:57 AM.

Bambu P1S/AMS

NVision4D http://nvision4d.com

-

12-14-2014, 10:34 AM #118

You need to reduce the motor temperature (reduce current) or add cooling to the motors. Adding more plastic to the mount is unlikely to help for long. You should have lots of torque headroom to reduce the current with those motors.

The NEMA14 motors I specify never get hotter than about 45C with the current pot set at .3V.

-

12-14-2014, 11:12 AM #119

This might help you Steve.

Turn the stepper the pots down to the very minimum, manually set an extrude (with no filament in to save materials) in gcode and start turning the pots up until the motor starts to run. All of my motors ran fine at the lowest amp setting. The torque was a bit weak though. I could stop the motor easily by holding the G2T pulley. So, I turned it's put up the tiniest bit. Now when I grabbed it, and couldn't stop it. At the very lowest pot setting that prevented me from overpowering the motor is where I set it. I did this for all my motors, not just the new extruder motors.

Now, for me, the printer is much quieter. It was never loud, but it was sometimes noisy. Now it purrs. It appears I was overdriving all of my stepper motors even though they were set at 1/4 of the range by default. I'd say the pots are at 1/8 right now. I can also hold all of my motors with bare fingers and they don't get so hot that I have to remove my grasp. So I'm with clough42, I'm somewhere around 45-50C.Last edited by RobH2; 12-14-2014 at 11:22 AM.

Bambu P1S/AMS

NVision4D http://nvision4d.com

-

12-14-2014, 11:49 AM #120

Agree the motor was very hot to the touch. I turned it down I'll do the min settings while running. Thanks for the suggestions.

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help