Results 111 to 120 of 476

Thread: Itty Bitty Double Extruder

Hybrid View

-

12-11-2014, 07:46 AM #1

-

12-11-2014, 08:41 AM #2

-

12-12-2014, 05:20 AM #3Technologist

- Join Date

- Nov 2014

- Location

- Orange, CA

- Posts

- 78

200g is really good for that TQ and the length fits within the belts

maybe a Nema 17ver is called for clough42

and my i3v is on it's way

keep an eye on the build log for updates

this mod will be on the list very soon

i just ordered 2mm pitch acme for my printer i want to get z a little faster and lets face it 4000 steps per mm is over kill 1000 steps per mm is damn good

2mm acme +16micro is still 1600 steps and if you take that in to account with the limits of the ATmega chips at around 16,000-18,000 steps per second

16000/1600 net me a max safe speed of 10mm/s in the Z axis

16000/80 is 200mm/s X or Y

this number has some flex to it but just remember each output stacks so a 100mm/s in Y and 100mm/s in X stacks to 200mm/s

this is thanks to the single core mini pin head of a brain AVR based controllers have

i wish amtel had a plain atmega with a 80mhz clock so normal firmware worked with lite mods and not a full rewrite.

but hey that just a dream right lol

-

12-12-2014, 08:59 AM #4Engineer

- Join Date

- Jul 2014

- Location

- Eastern Colorado

- Posts

- 536

If that 2mm acme works out for you, I may try that at some point. Sure, the .8mm pitch rod that came with the kits allows a theoretical 0.00025mm layer height, but I never attempted anything below 0.1mm layers. I don't think I'll have any need to get that level of detail in Z.

-

12-13-2014, 08:58 PM #5

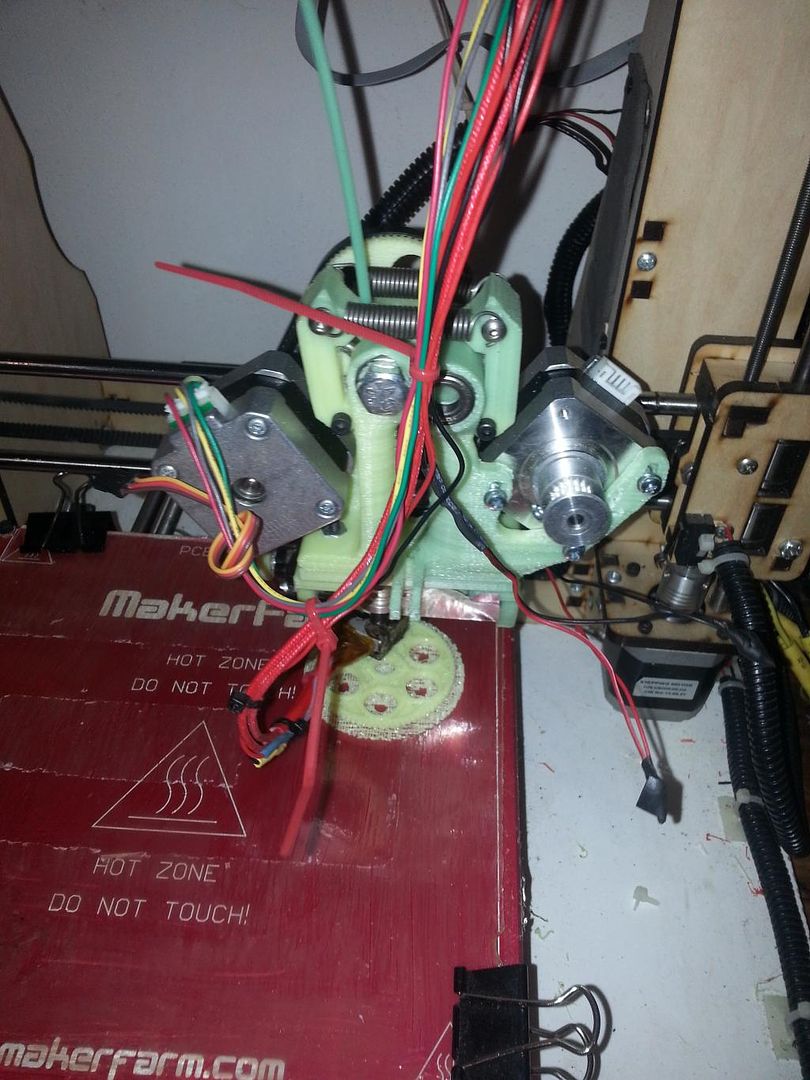

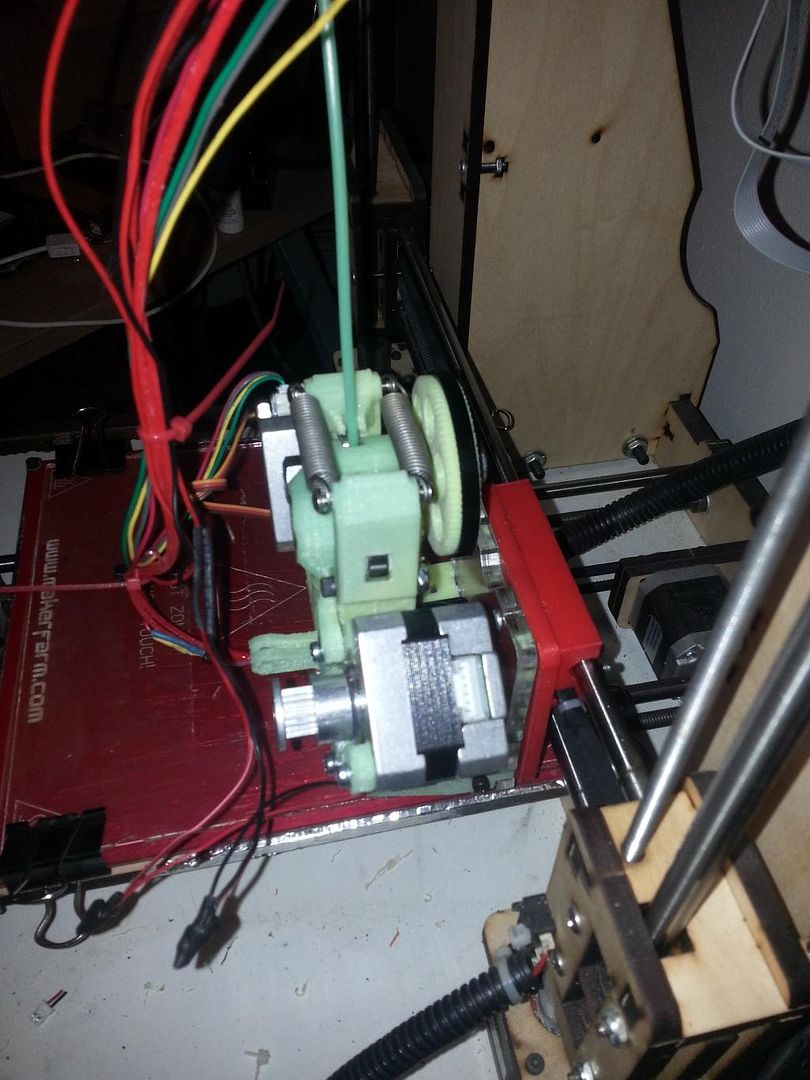

First print with the Itty Bitty Nema17 Modified Magma hot Ends. . We are only using one drive as someone ordered the wrong hobbed bolts (That would be me). So far its printing nice without any setting changes. Very happy with the fit form and function thanks RobH for the 17 model and Clough for the design. still need to tidy up the wires and get the auto bed level working.

-

12-13-2014, 09:52 PM #6

Really good to hear. So the main body rebuild was good? Any tolerance issues?

Bambu P1S/AMS

NVision4D http://nvision4d.com

-

12-13-2014, 09:57 PM #7

Just discovered and issue when the motor mounts heat up the attach points sag causing the belt to loose tension. It will need to be reinforced.

-

12-14-2014, 10:34 AM #8

You need to reduce the motor temperature (reduce current) or add cooling to the motors. Adding more plastic to the mount is unlikely to help for long. You should have lots of torque headroom to reduce the current with those motors.

The NEMA14 motors I specify never get hotter than about 45C with the current pot set at .3V.

-

12-13-2014, 10:34 PM #9

Tell me what you think will fix it. Maybe a plate with 4 holes and a center hole for for the pulley? I can put a hole in the middle for it to stick through. Maybe the arms are a bit thicker? Tell me what you need and I'll modify it.

Bambu P1S/AMS

NVision4D http://nvision4d.com

-

12-14-2014, 12:25 AM #10

This is not the prettiest model but it might do the trick. If so, I'll make it nicer later. I know it's a long print but if you think this will do it give it a go.

It must warp a alot because the best part about 'clough42' using belts is that they don't skip unless they get really loose. Are you pushing too many amps through the motors maybe? Mine don't run very hot.

Nema17_Versions.jpgLast edited by RobH2; 12-14-2014 at 10:57 AM.

Bambu P1S/AMS

NVision4D http://nvision4d.com

Reply With Quote

Reply With Quote

Please explain to me how to...

05-13-2024, 03:08 PM in 3D Printer Parts, Filament & Materials