Results 3,431 to 3,440 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

09-30-2016, 03:09 PM #3431Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

09-30-2016, 06:10 PM #3432Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

-

09-30-2016, 06:14 PM #3433Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

09-30-2016, 06:51 PM #3434Technician

- Join Date

- Sep 2016

- Posts

- 80

Gawd, it's still going.

Can't wait to see what the final readout is. I'm fairly certain we're at probably 20 hours and we're at 80%.

-

09-30-2016, 06:55 PM #3435Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

09-30-2016, 08:34 PM #3436Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

Problem on the QIDI X-ONE. I was doing a long print and I think the X stepper overheated. The gantry got stuck to one side and was real hard to move. turn the power off then back on and it moves freely but the motor was very hot.

How can I turn down the current to it if that is a good thing to try? It is a Marlin type board I believe. The scripts in S3D are very minimal due to it being a pre-release profile I am testing.

I remember some of you doing this on the Tech-1.

Maybe there is something else I should look at?

Thanks.

-

10-01-2016, 12:20 AM #3437Technician

- Join Date

- Sep 2016

- Posts

- 80

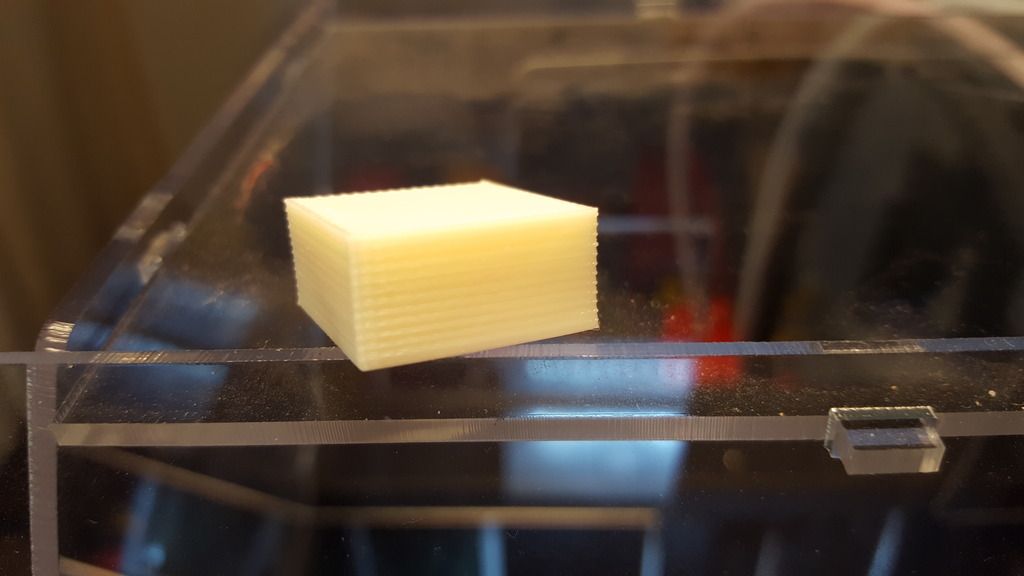

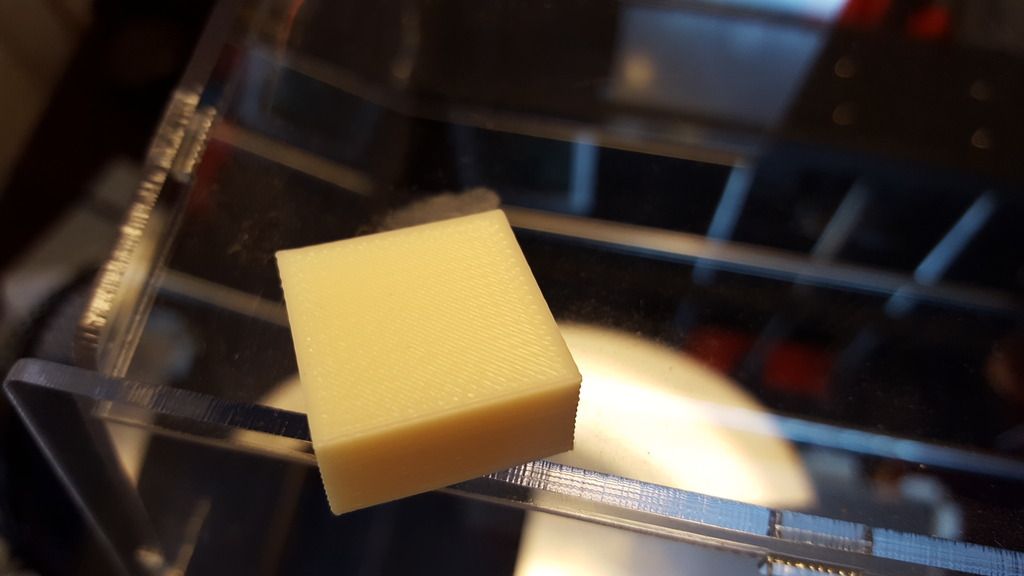

I was printing one of these: http://www.thingiverse.com/thing:1065206

I went for maximum size on the Qidi. 25 Hours, 36 minutes. Looks pretty good, I'll get a picture tomorrow.

-

10-01-2016, 01:25 AM #3438

-

10-01-2016, 01:40 AM #3439Editor in Chief

Bitsonline

Tips Appreciated But Not Expected

BTC: 16wxHvKd3oU6SVjv6FrenqhkvRmc8t7sPy

DASH: XqyaWxH896j9YeV1M35Gzb5gmRPmPbNDGq

-

10-01-2016, 05:54 AM #3440Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

Reply With Quote

Reply With Quote

New to 3d printing looking for...

05-20-2024, 12:56 AM in Tips, Tricks and Tech Help