Results 11 to 20 of 71

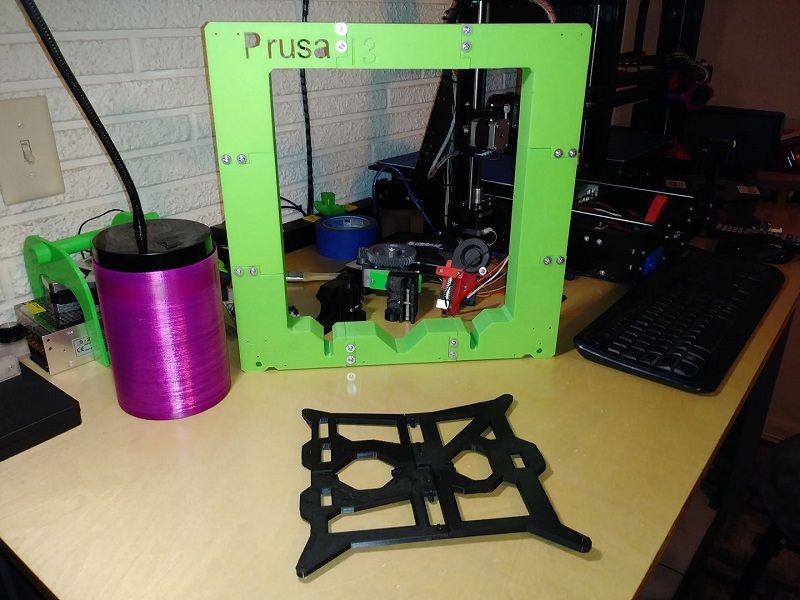

Thread: 3D Printed 3D Printer

-

07-24-2017, 06:57 AM #11

any idea what weight of filament you'll use for the whole thing ?

Wondering if using plywood might not have been more cost effective for the frame, and quicker.

Not as much fun - obviously, but maybe more practical :-)

-

07-24-2017, 05:18 PM #12

<2.2lbs. I used a spool of filament I had laying around. Nothing is more cost effective or practical than using what you have laying around

Last edited by AutoWiz; 07-24-2017 at 05:26 PM.

-

07-24-2017, 07:22 PM #13

-

07-25-2017, 09:56 PM #14

I went to lowe's today and spent quite literally a few bucks on some threaded rods for the Y axis. Sadly they were too short. But also the Y carriage is meant to hold 3 short lm8uu bearings and I only have 2 short and 1 long lm8uu bearing on hand. So either I need to totally blow up the budget here or get creative with the printers. It's a tall order to not spend more money here. Aside from the z axis motor and top mounts I now need to design and print out Y axis ends that will extend the threaded rods and make adapters to space the bearings down below the plate a touch so I can mount the larger bearing and still have a level plate. During the week progress slows as I have to work and only have a few hours in the evening to do stuff.

-

07-25-2017, 10:05 PM #15

I have to take a second and brag about what I do for work. Seriously. Playing with plastic is cool. It is a fun way to kill time and be creative without getting dirty. But the things I build that pay the bills require a little more effort to produce..

1969 Pontiac GTO: https://www.superchargerforums.com/t...ring-gto.3135/

1967 Chevrolet Corvette: https://www.superchargerforums.com/t...n-a-7-0l.3130/

1996 Chevrolet Impala SS: https://www.superchargerforums.com/t...ntroller.5211/

It is nice unwinding with these plastic making toys at the end of a hard day's work.Last edited by AutoWiz; 07-25-2017 at 10:56 PM.

-

07-25-2017, 10:44 PM #16

-

07-25-2017, 10:54 PM #17

Alright, one last thing about my day job and then I will stop. I promise. Look what recently came in for a supercharger..

This car came to me so I can make it go as fast as it looks. And that is why I have to brag on this so hard. I LOVE my job and what I do. Life is too short to be miserable. Everyday I am excited about what I do at work. And I hope the rest of you are as well.Last edited by AutoWiz; 07-25-2017 at 11:02 PM.

-

07-25-2017, 11:13 PM #18

I guess this is probably my favorite part of the job. The reward at the end. The generation of numbers to verify and confirm a job well done..

https://www.youtube.com/watch?v=JW6Zkih4VjE

https://www.youtube.com/watch?v=kPQy2SF3ESw

https://www.youtube.com/watch?v=7sOe9bnGHlE

https://www.youtube.com/watch?v=3b_kdVKu3GY

https://www.youtube.com/watch?v=l7008Ydrv3Q

https://www.youtube.com/watch?v=nMeRiU8CHOM

https://www.youtube.com/watch?v=A8EWbc3ym7M

I'm gonna stop here so this doesn't drag on but You all gotta know I have A LOT of dyno videos. It is the pat on the back at the end of the job. You wind the car out before and after the job and you know exactly what you did. It is awesome. And I got to be a big part of the install of our Dynojet224xlc also:

http://www.digitalcorvettes.com/foru...d.php?t=257986

-

07-26-2017, 05:48 AM #19

what is the white car ?

I'm not an american car fanatic so have no clue. Looks like a porsche to me - but I'm guessing not :-)

Got a mate at a local garage who does supercars for a local dealer. Not unusual for him to have a limited edition ferrari that used to belong to a celebrity worth multi millions in for a service.

Although my favourite car of recent times is the BMW Z1 - I absolutely LOVE these doors :-)

-

07-26-2017, 08:55 AM #20

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help