Results 1 to 10 of 71

Thread: 3D Printed 3D Printer

-

07-19-2017, 07:50 PM #1

3D Printed 3D Printer

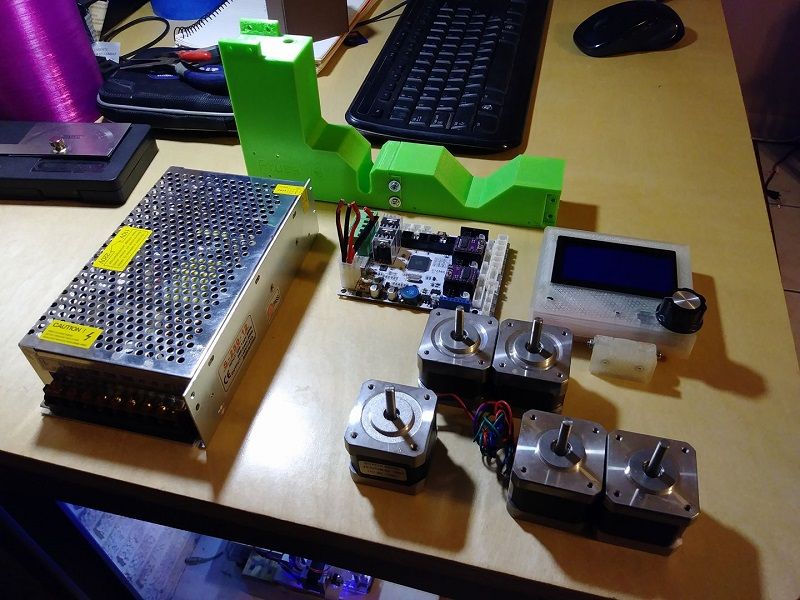

I have a friend who is interested in 3d printing but really can't afford a printer. And I have all these parts left over from so many rounds of upgrades on so many printers so I am going to build my friend a 3d printer and give it to him so he can start making stuff, too. I have found an old design from 2013 of a printable i3 frame: https://www.thingiverse.com/thing:146061 . And this thread is dedicated to the printing of this frame and subsequent building of a prusa i3 printer from spare parts.

-

07-19-2017, 08:19 PM #2

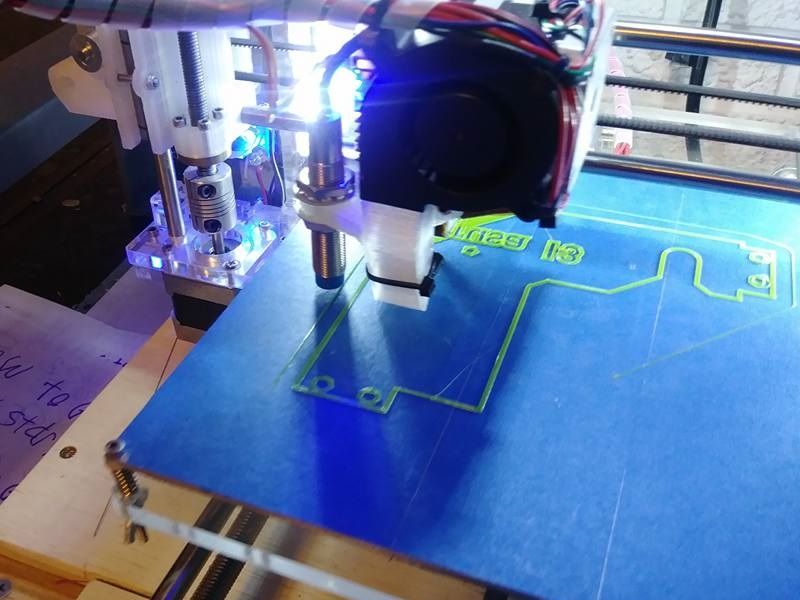

Of course we are gonna print the i3 frame on the i3..

I have my GEEETech i3 configured with an mks base control board, 0.9 degree stepper motors on X, Y, and in the mk8 extruder, and a 0.3mm nozzle diameter. It is laying down the filament nicely..

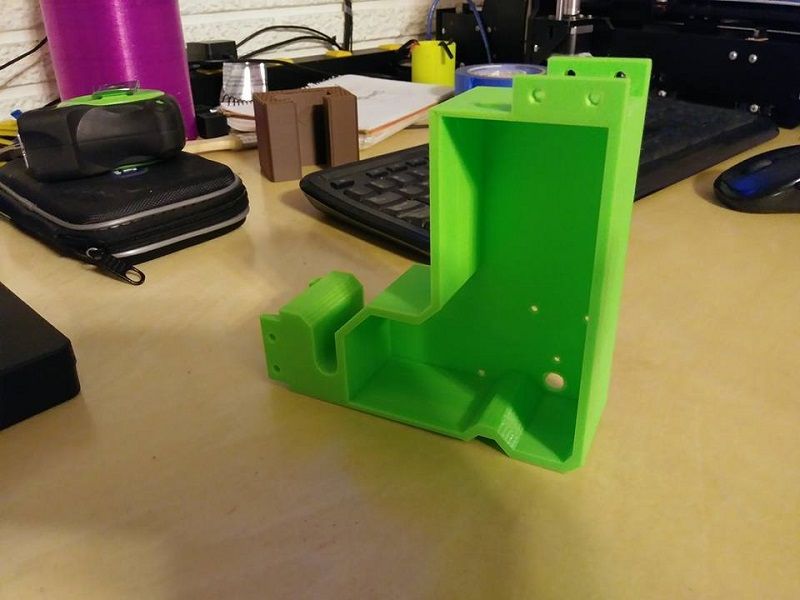

It is going to take a while to print this frame. This is the first of 8 large pieces just to make the main structure.Last edited by AutoWiz; 07-19-2017 at 08:26 PM.

-

07-20-2017, 04:34 PM #3

-

07-20-2017, 07:02 PM #4

-

07-20-2017, 10:36 PM #5

-

07-21-2017, 04:40 PM #6

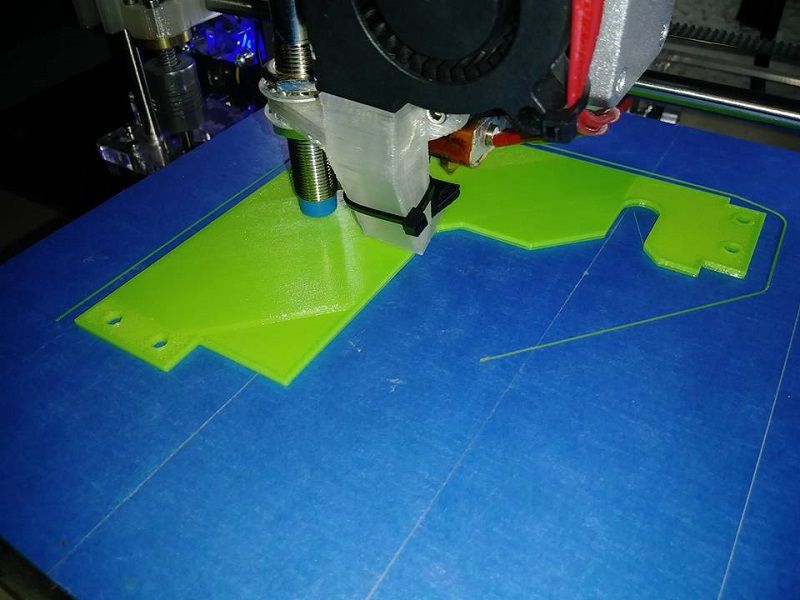

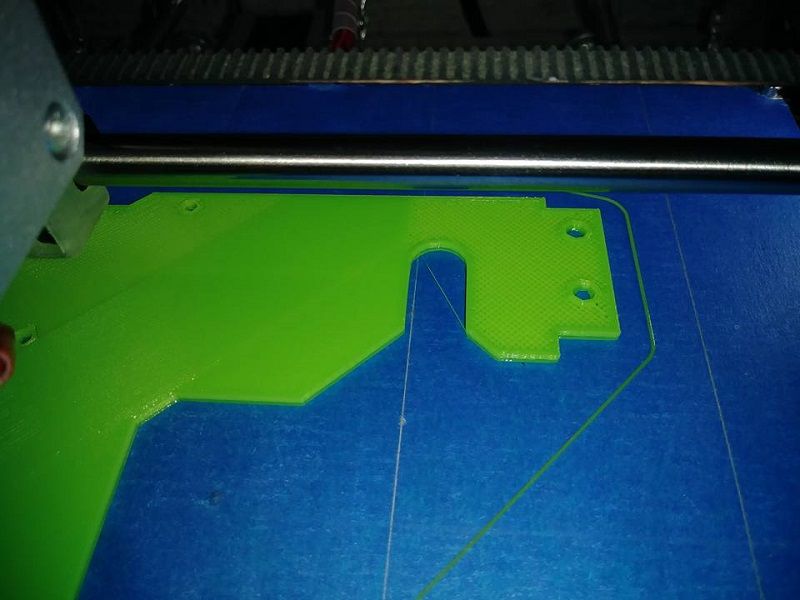

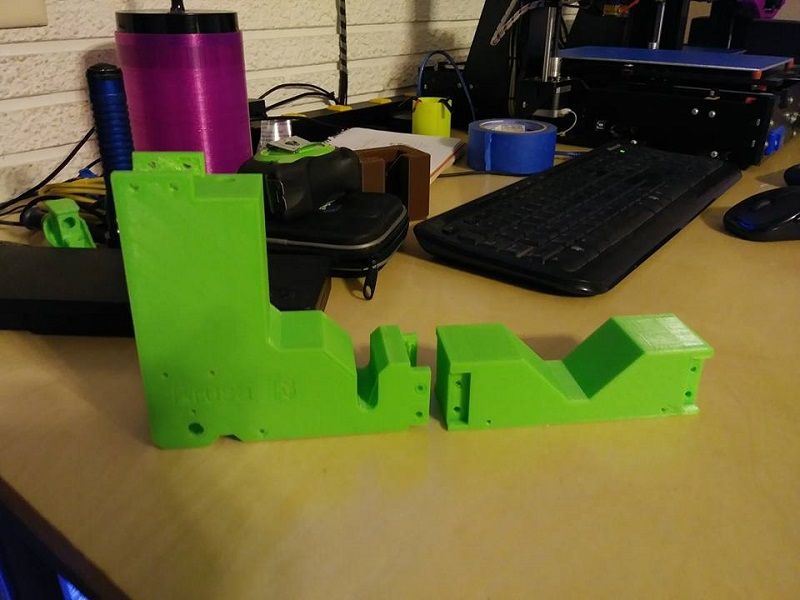

No I am building this alone and sending pictures of my progress. I am not going to modify the frame but I am saving all the sliced .gco files that I used to build the frame with so if any parts break my friend can re print it and keep going. If any part keeps breaking then I will address that issue. Today I have finished the 3 lower pieces of the frame..

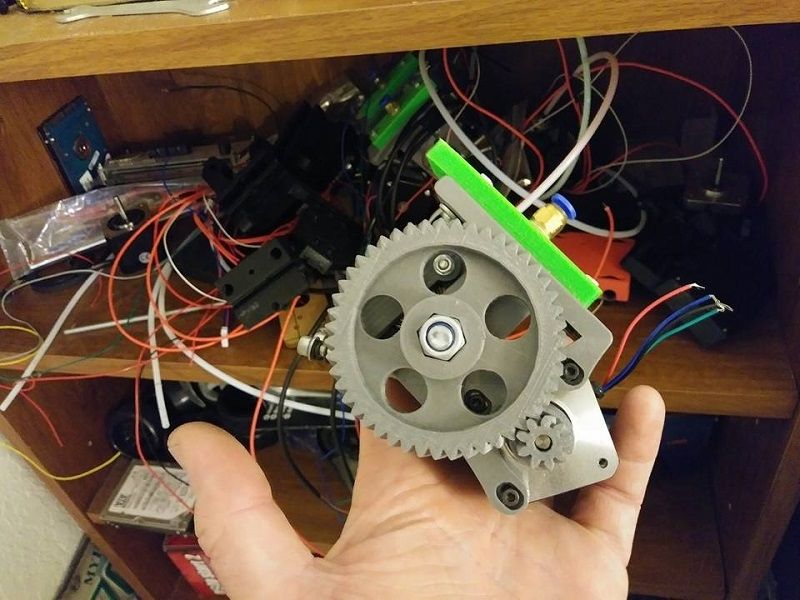

And I think I am going to use one of the three wade extruders I have laying around left over from this idea went wrong: http://3dprintboard.com/showthread.p...Mixing-Printer

-

07-21-2017, 09:45 PM #7Student

- Join Date

- Jul 2017

- Posts

- 42

This is fantastic! Exactly what I would do in this situation with spare parts at hand. I doubt I know anyone into 3D printing themselves but building one like this is such a learning experience. Look forward to the finished product.

-

07-21-2017, 10:31 PM #8

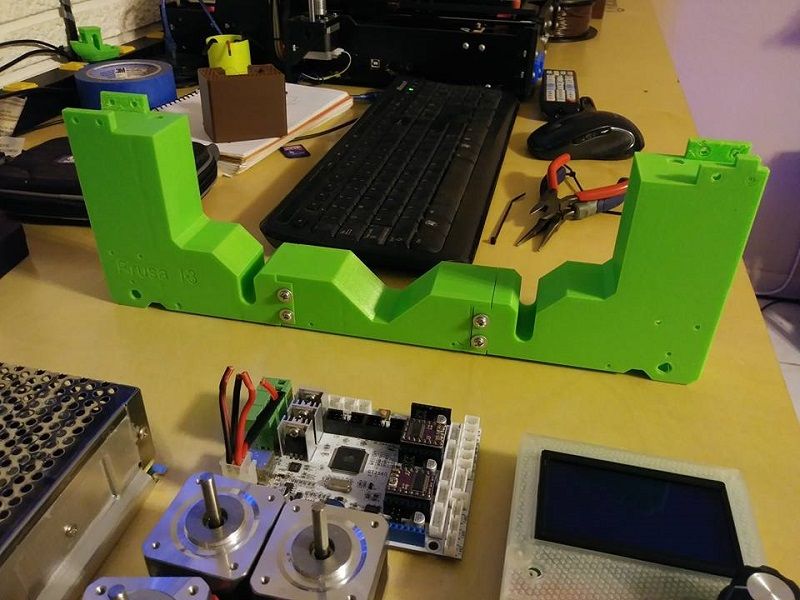

Thank you for the positive feedback guys. I am having a blast, getting rid of some parts I wont otherwise be using, and hopefully creating a friend with a like hobby. We will see how all this pans out. I reconfigured my printers often and a lot getting them to where they are now. Sometimes I just printed out and changed parts to change color. It kept me busy then and now I have a selection to choose from in building this machine..

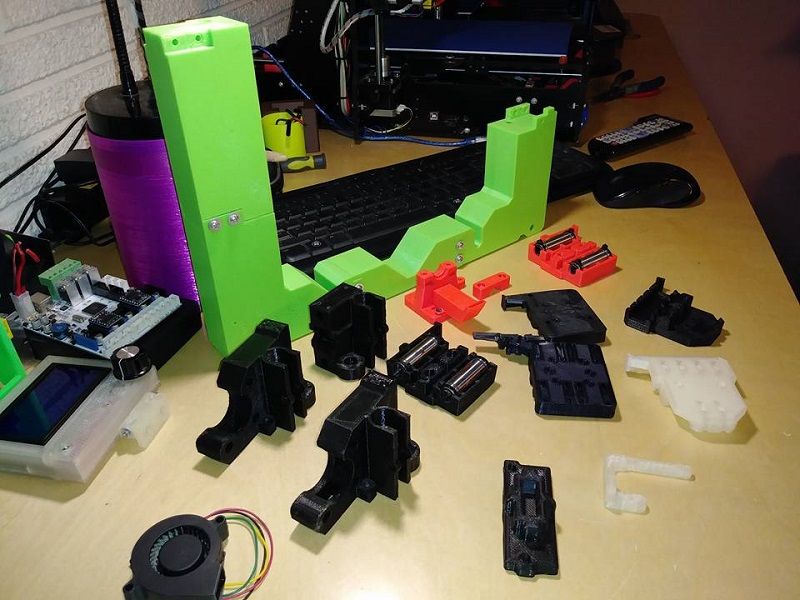

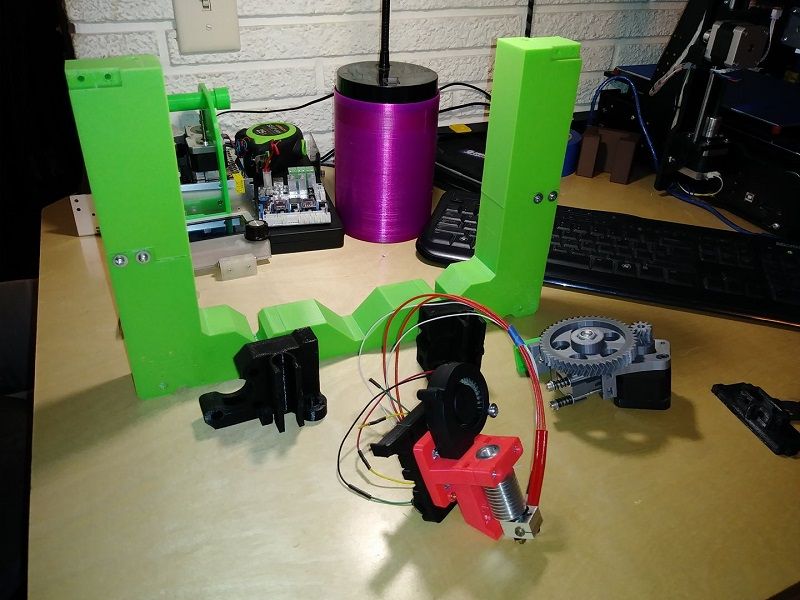

Using these parts will save me time and materials. If my friend wants it all green that will make for a nice first project with his new printer. So these are the printed parts I will use and now we can really start to get a picture of what this printer is going to look like..

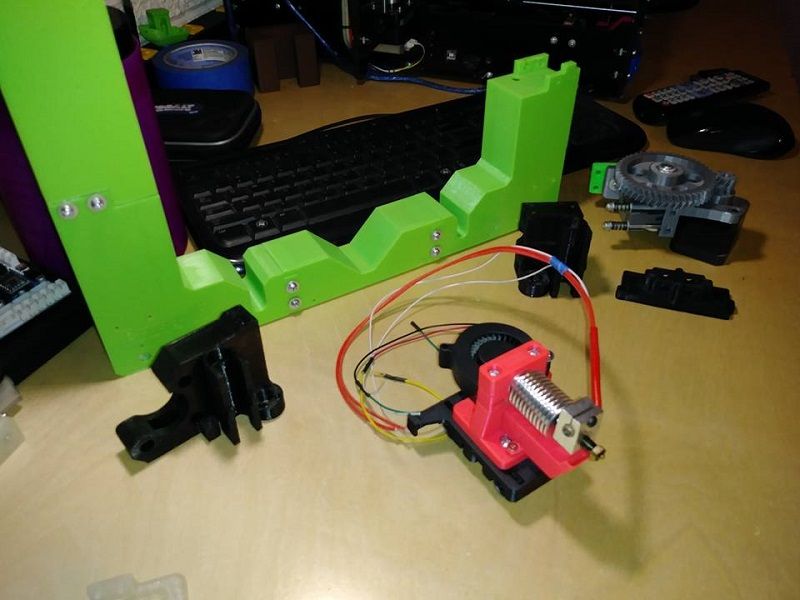

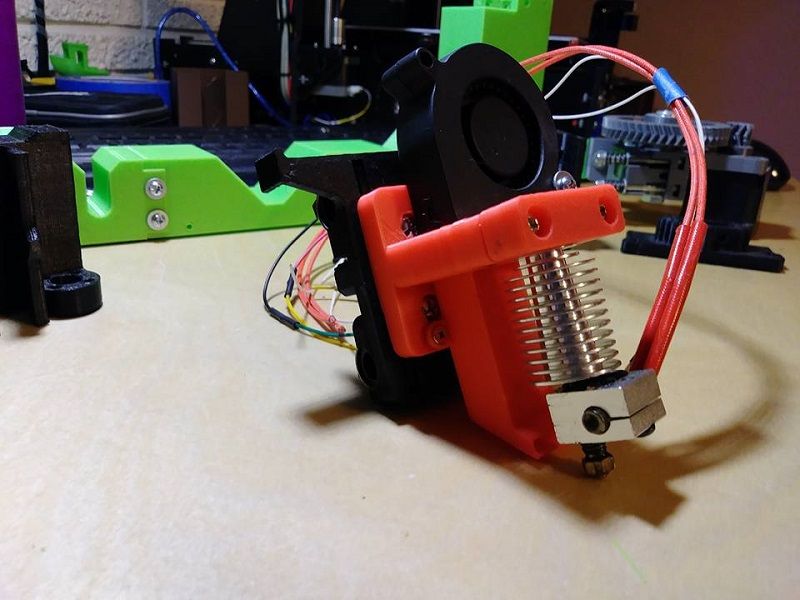

This e3d v6 mount was a design I found also on thingiverse. I really liked how it mounted the layer fan. This should make a good extruder for this machine..

I have an mk8 extruder but I feel with the printed frame it is best to try to keep weight off the gantry.

-

07-22-2017, 02:26 PM #9

I have a career that requires my attention for a large chunk out of each day: http://www.corvette-performance-expert.com/ And while the wife doesn't work and all 3 kids are home from school for the summer they all keep going out and doing stuff and I don't want to trust a printer to run without anybody at the home so this has created a limitation that coupled with the print time for each piece has me building this frame at ruffly 1 part per day. Here is today's part installed..

-

07-23-2017, 08:26 PM #10

At the end of the weekend I am one piece away from completion of the frame..

The ham on the right is my youngest child, Drew. Of my 3 kids he has taken to this hobby the best. The others I force my projects on but little 7 year old Drew knows how to make stuff in autodesk 123d design, export as .stl, load in repetier, configure and slice and print with all of my printers. I am very proud of him. And I started printing out the y axis carriage. I am printing that out with the monoprice printer in an effort to speed this along.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

Yesterday, 02:02 PM in Tips, Tricks and Tech Help