Results 1 to 7 of 7

Thread: 12" heatbed relay issues

-

01-14-2015, 12:11 PM #1Engineer

- Join Date

- Nov 2014

- Posts

- 522

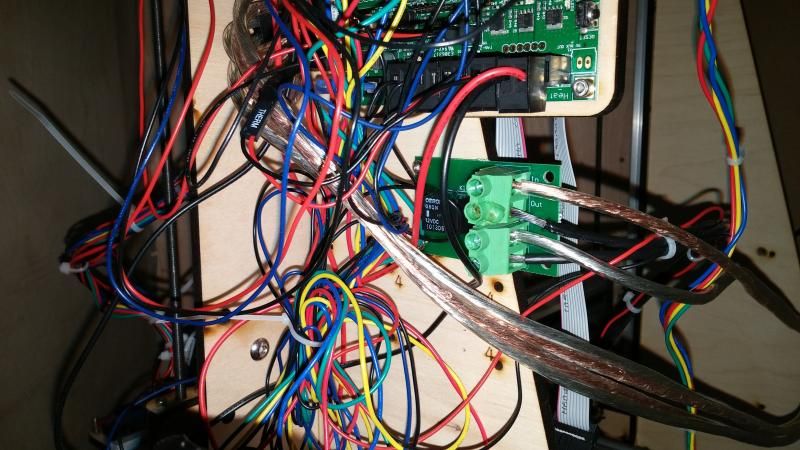

12" heatbed relay issues

So ive got a problem...

Thoughts for a solution?

I hear a click when i set the heatbed temp but it seems that its no longer making contact internally. So i guess i need to order another relay or find a terminal to solder in.

-

01-14-2015, 01:15 PM #2Technician

- Join Date

- Nov 2014

- Posts

- 58

its that melted plastic in the "out" output? . something that i have notice is that this terminals needs to be tight very well because the tends to loose . if you hear a click your relay is working but maybe you no longer have contact in that output . you can find those type of terminal in a local electronic supply store . also i suggest that you put the negative wire passing thru the relay instead of the positive .

worst case you can solder the wire directly on the back of the plate on that output (be careful no to short it)

also looking at the pic i think you have your heater 0 (extruder heater) invertedLast edited by pichuete; 01-14-2015 at 01:23 PM.

-

01-14-2015, 01:24 PM #3Engineer

- Join Date

- Nov 2014

- Posts

- 522

Since its a resistor it doesnt matter. They are bidirectional.

Hopefully radioshak has some... Otherwise im direct soldering to the board.

-

01-16-2015, 11:39 AM #4Student

- Join Date

- Aug 2014

- Posts

- 24

Assuming the relay is still working, why don't you remove both wires from the top connector and solder them together. The relay will still be able to open/close the second connector which will still connect or break the circuit for the heatbed as needed. I think this actually recommended on another thread on here.

-

01-16-2015, 12:32 PM #5

-

01-16-2015, 02:16 PM #6Student

- Join Date

- Aug 2014

- Posts

- 24

I wasn't aware of that, Thanks for the info.

-

01-16-2015, 06:40 PM #7Engineer

- Join Date

- Nov 2014

- Posts

- 522

I actually fixed it a somewhat difficult way but seemed like a good idea at the time. I directly soldered the wires to the pads after removing the terminal and on the back side i scotch brited the coating off and built up the trace with solder so there shouldnt be any heat buildup and it should handle the current more easily. As that is the positive side. The negative side is through the relay. Not that it matter really the heat bdd is bidirectional.

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help