Results 1 to 10 of 21

Thread: Extruders

-

07-05-2017, 03:24 AM #1Technologist

- Join Date

- Jul 2017

- Posts

- 184

Extruders

As you may be able to tell from my other thread, I'm designing a printer. And a big thing I'm trying to decide on is the extruder (that and build area but that's easier to customize later).

The obvious question is bowden vs direct, and my answer is I'll design it so it can use both interchangeably. What I really want opinions on are geared vs direct, and single sided (with idler) vs double sided drive (two driven hobbed gears grip filament from both sides).

I only really have experiences with a direct drive mk 8 type extruder, so other people's experiences and opinions are very much welcome. I understand that gearing the motor gives you more torque and more resolution, but what is that torque good for (able to force more filament through the extruder so faster print speeds than non geared? Or do printers never go so fast as that this becomes a problem), and is the extra resolution necessary?

Secondly, with double sided drives like the bondtech, this means you have more grip on the filament and are less likely to slip and grind the filament, but again, is this really an issue? I also imagine you'd have more precise control than with an idler and can do faster retractions and extrusions as the hobbed gears or bolts are less likely to slip when there's two of them.

Thanks in advance for any ideas, opinions or suggestions!

-

07-05-2017, 06:47 AM #2

I can chip in a bit.

Got two makerbot clone direct drive machines and one 200x270 delta with a one sided drive. Ie: grooved wheel pushes the filament against a single hobbed bolt on a bowden system.

the bowden prints faster and with at least as much precision. It will also print ALL flexible filaments, faster than the direct drive machines.

Even ninjaflex and filaflex.

So going on recent experience - you definitely do not need a double hobbed bolt drive setup.

The really important thing is to make sure there are NO gaps anywhere in the feed system. Filament must be given no alternative route right from the extruder to the nozzle. I think that's why the bowden setup prints flexibles faster and better than the direct drive machines. I've eliminated any gap in the feed system and got the feed tube down to it's optimal (shortest length without sharp angles being able to form) length.

-

07-05-2017, 09:41 AM #3Technologist

- Join Date

- Jul 2017

- Posts

- 184

I fully intend to make sure there is a fully supported filament path, regardless of any other choice I make for the extruder i.e bowden/direct drive, geared or not, single or double sided drive.

Just a question, what sort of speeds do you print flexiblez at on your bowden? And what sort of speeds do you print at in general?

The double sided drive and geared extruders from what I understand only really shine with high print speeds, you dont need the extra grip and torque at 80mm/s but you might at 150/200 mm/s

-

07-05-2017, 10:14 AM #4

with the replicator clones max speed is 65mm/s for pla and around 20-30 for polyflex - flexible pla.

Neither of them will touch ninjaflex or filaflex.

So far on the he3d k200 delta. I've gone up to 100 for pla - at 0.3mm layer height - so a fair volume of plastic going through the nozzle, 50 for polyflex and 20 for ninjaflex and filaflex.

Petg - I think - I printed at either 50 or 60 with 0.1 and 0.2mm layer heights.

Pretty sure she'll go up to 150 for the right high speed pla.

-

07-05-2017, 10:46 AM #5Technologist

- Join Date

- Jul 2017

- Posts

- 184

I'm hoping to make a high speed printer, definitely above 100 mm/s for pla (thinking 150+). As for flexibles, with some minor modifications to my mk8 style extruder I could get TPU printing at 60-70 mm/s at 0.25 layer height (I'm a very impatient fella haha) so I'm aiming for better than that, at least for my direct drive variant.

But yeah, I agree, at 100mm/s PLA you wouldn't need or possibly even see the difference between single and double sided drive.

This thread has a good comparison photo if you scroll down.

https://ultimaker.com/en/community/1...1#reply-120122

-

07-05-2017, 11:27 AM #6

Flexion:

https://flexionextruder.com/

or

Titan:

http://e3d-online.com/Titan-Extruder...FSsW0wod10wE4Q

These are the top end solutions on the market right now. Flexion is a direct drive in the sense that the hobbed gear sits right on the stepper motor shaft 1:1 but it has a brushed wheel that keeps the hobbed gear clean.

The titan has 3:1 gear reduction for finer precision or more steps/mm of filament travel 3x more and also all the extra torque that comes with 3:1 gear reduction.

-

07-05-2017, 04:47 PM #7Technologist

- Join Date

- Jul 2017

- Posts

- 184

Have you used either/or any similar extruders? The flexion isn't too different from any other extruder, the brush is there because the deeper hobbed gear grinds harder filaments like pla and abs (non flexibles) a bit more, and it has a fixed, positive pressure idler rather than a spring loaded one. That last feature I find pretty cool and I'll make sure my hot end can do both spring pressure and positive pressure and switch between them easily.

As for the gearing, I'm not sure how useful it is, what positive effect does it have on prints and is that finer resolution noticeable in the end result? Again, I suspect it shines more at higher speeds where you need to push more plastic through the extruder.

-

07-05-2017, 05:17 PM #8

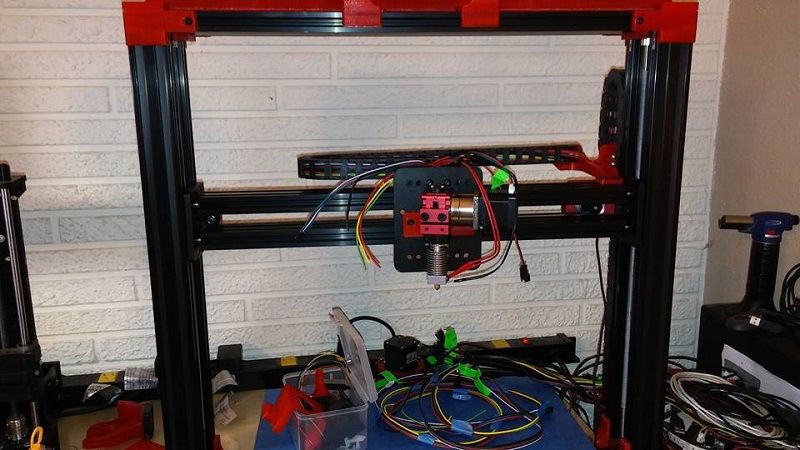

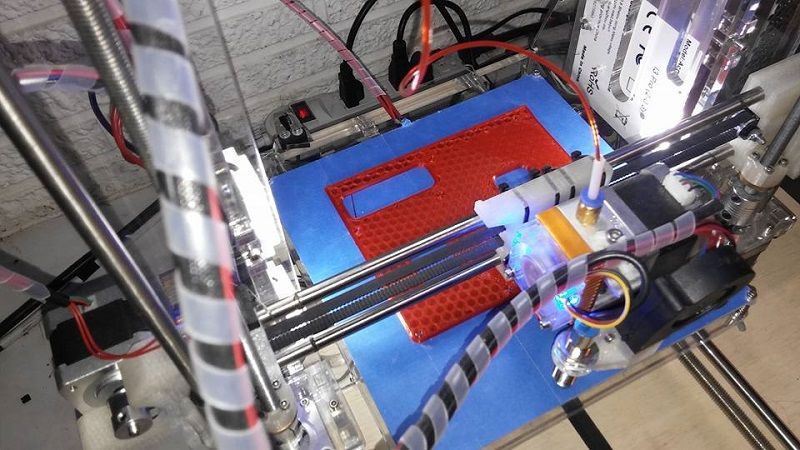

The gear reduction will shine more at slower speeds and also in more precise retraction control. because it is 3x as many steps to travel the same distance. It also shines when you start dropping layer height and / or nozzle sizes and the filament is always moving slow. The gear reduction lets the stepper motor spin at a faster rate which is nice when it is barely crawling along. As far as experience with extruders goes ya I have a little under my belt. In fact of the 4 printers I own 3 are dedicated to never ending upgrades, mods, and conversions for the sake of collecting knowledge. Here is one printer of mine that has seen 4 different extruders: http://3dprintboard.com/showthread.p...Mixing-Printer

And it is continues here: http://3dprintboard.com/showthread.p...twork-Printers

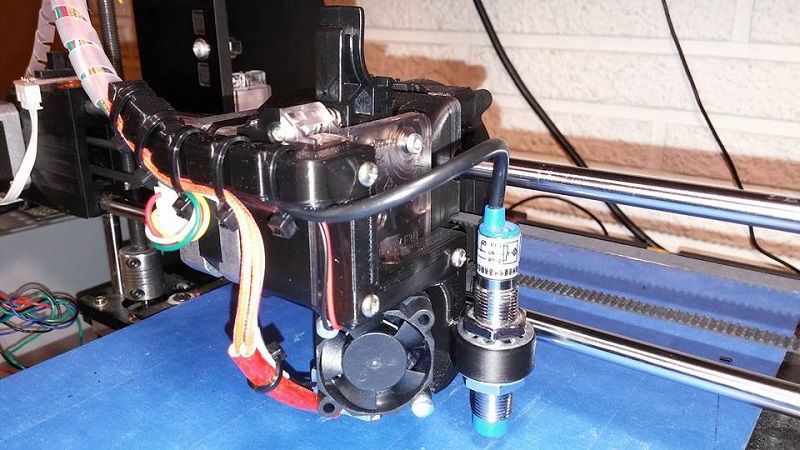

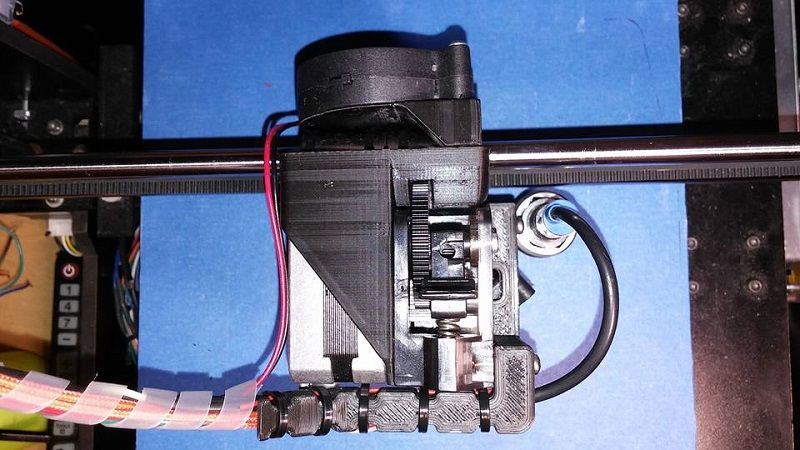

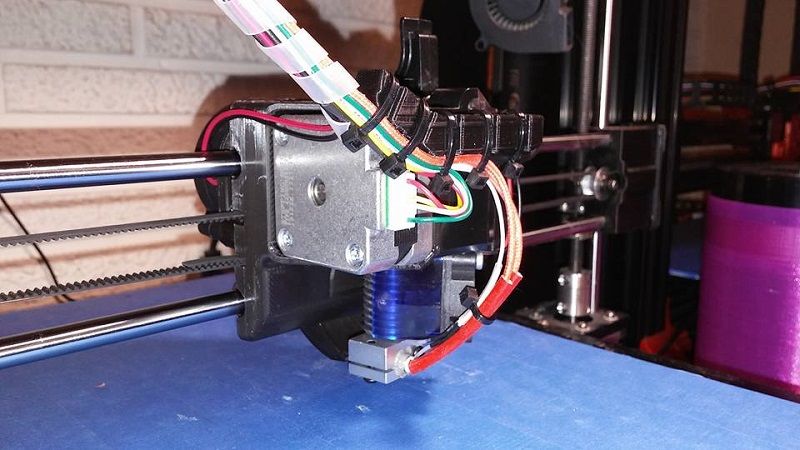

That printer runs a titan extruder now. Here is how I have my titan configured..

Last edited by AutoWiz; 07-05-2017 at 05:53 PM.

-

07-05-2017, 06:09 PM #9

-

07-05-2017, 08:07 PM #10Technologist

- Join Date

- Jul 2017

- Posts

- 184

I've read that gear reduction actually makes retraction less precise, due to backlash in the gears. I'll look at gear reduction, and I'll probably end up making a geared and un geared version of my extruder. To be honest I quite like the idea of a double sides drive, it looks cool at the very least and the thread I linked has some evidence that it helps the extruder keep up at higher speeds, plus it would add a bit to precision since you've got a more secure grip on the filament.

My main question at this point is whether a geared or direct driven extruder can extrude at a higher rate, I understand geared has more precision for obvious reasons.

Reply With Quote

Reply With Quote

Printing time- Is this right?

09-13-2024, 07:51 AM in General 3D Printing Discussion