Results 21 to 30 of 354

Thread: 370mm X 250mm X 300mm

-

03-23-2017, 05:09 PM #21

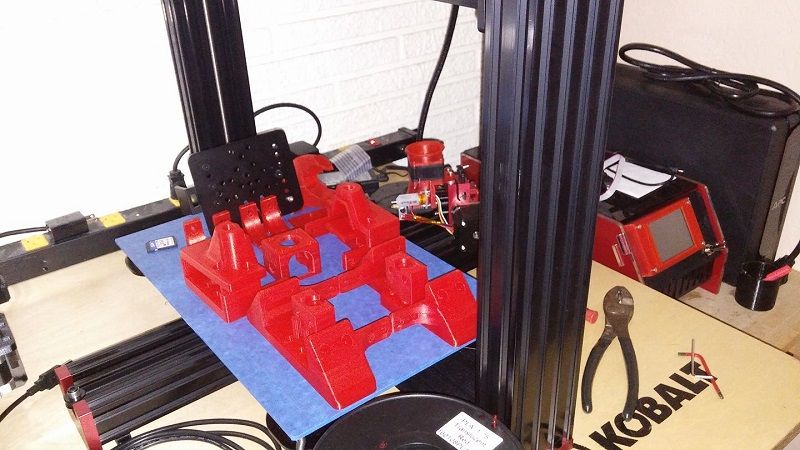

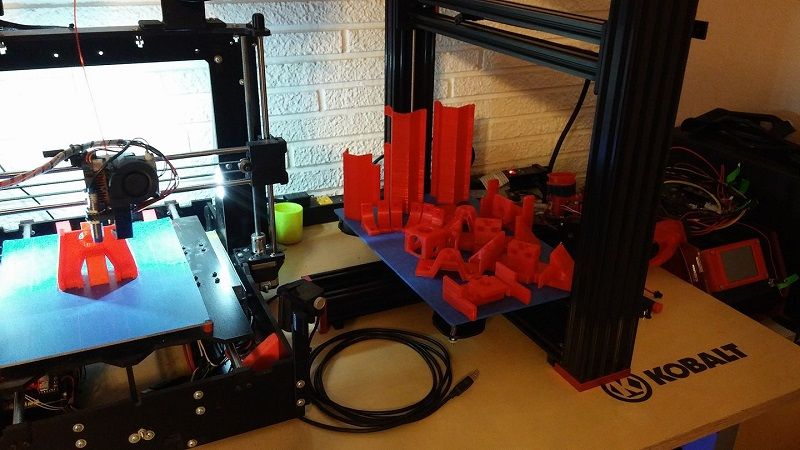

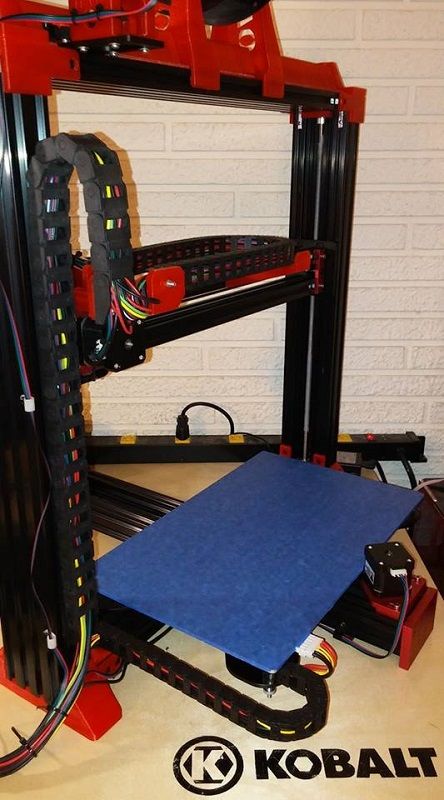

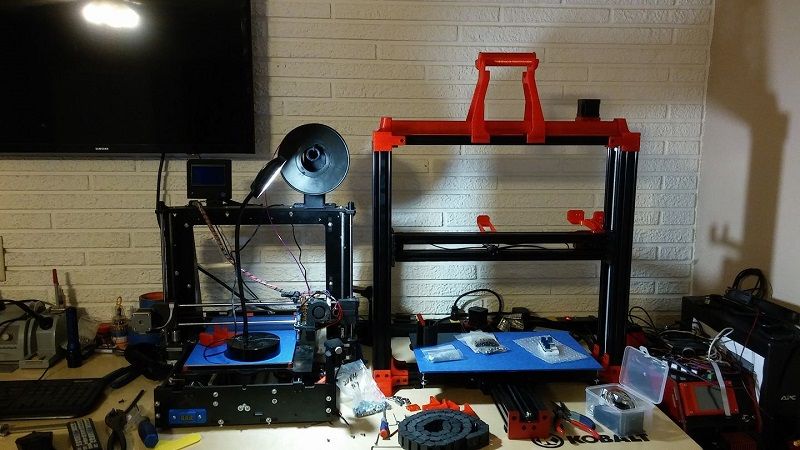

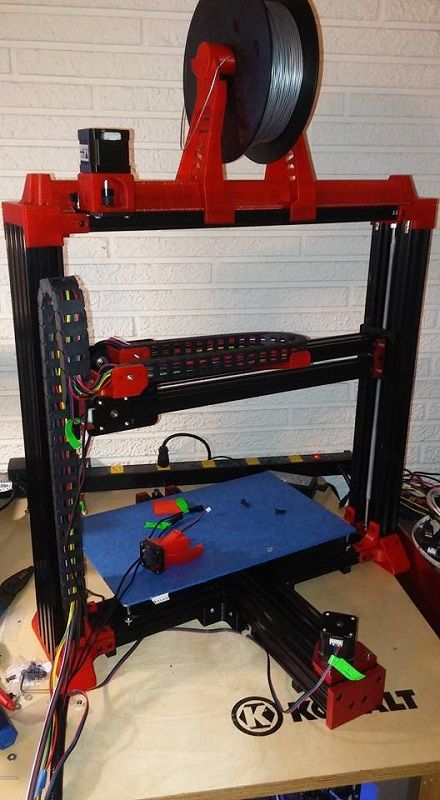

I have only used my homemade printer, printalicious, to make parts for this new machine. That printer has and is really impressing me. The z axis mod I am trying to make happen on this tevo black widow involves a lot of large printed parts. I am printing them all in translucent red pla. I am almost an entire week into printing parts non stop. I rush home on my lunchbreak from work to remove part from the print bed and start the next print. Here is where I am so far..

-

04-09-2017, 08:07 PM #22

There have been a lot of parts to print to make this printer growth go down..

And sadly some pieces I had to print multiple times. Not that printilicious isn't up to the task but because of trial and error of printing at different angles and support material that doesn't always like to release. A good example is the pieces that make up the filament spool holder. Here is what happened while removing the support material..

My home made printer is not the fastest and each of those pieces took 8 hrs to print. It is good that I can be patient with this build in the pursuit of perfection. I printed a third piece and was careful removing the support material..

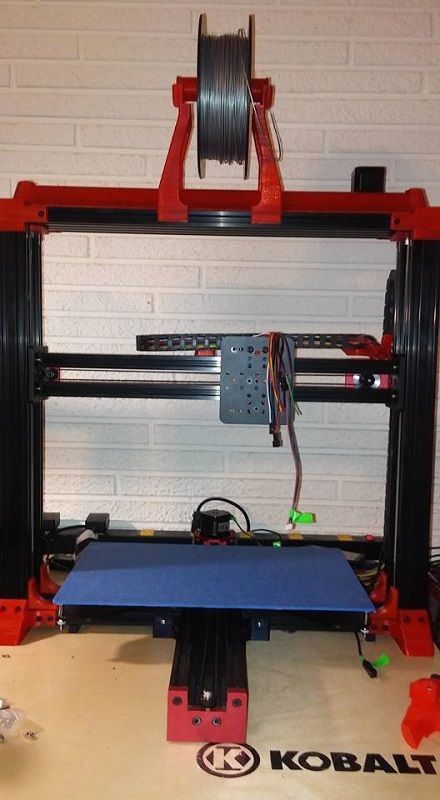

And this is the assembled spool holder. It will sit on top of the frame..

And as I understand that there is a problem getting the extruder all the way to the ends of the bed I have decided to add this very specific 8mm gap on both side pieces of the frame. I printed a 8mm block to help as an exact measurement..

I will also have to add this gap to the top of the frame and also to the x axis but in the end I will have every bit of the possible bed dimensions and a very respectable build height. well over the title of this thread

-

04-17-2017, 05:40 PM #23

-

05-04-2017, 10:58 PM #24

-

05-06-2017, 08:22 PM #25

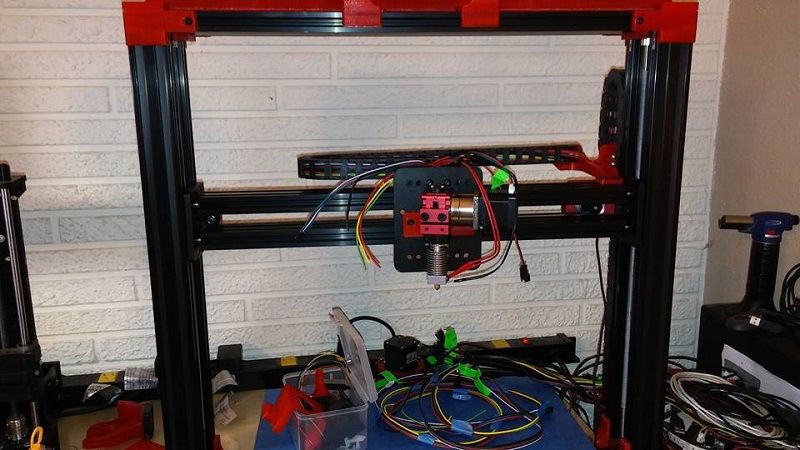

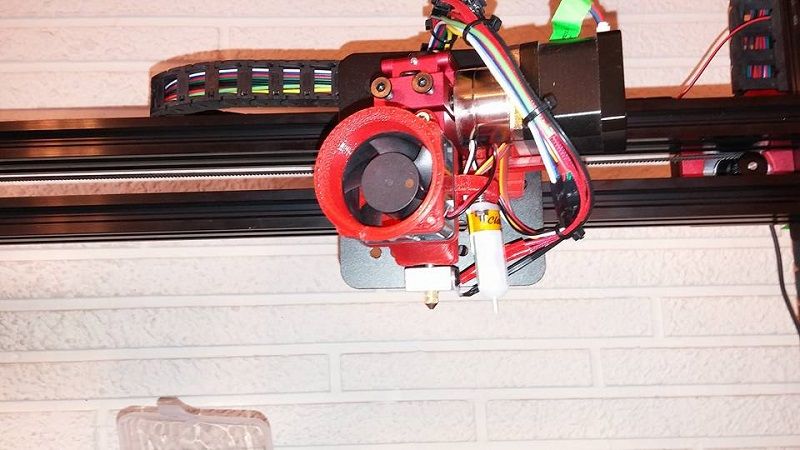

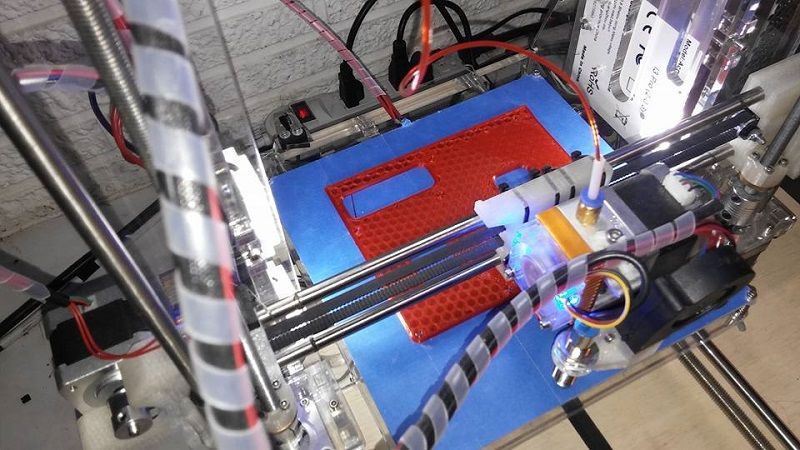

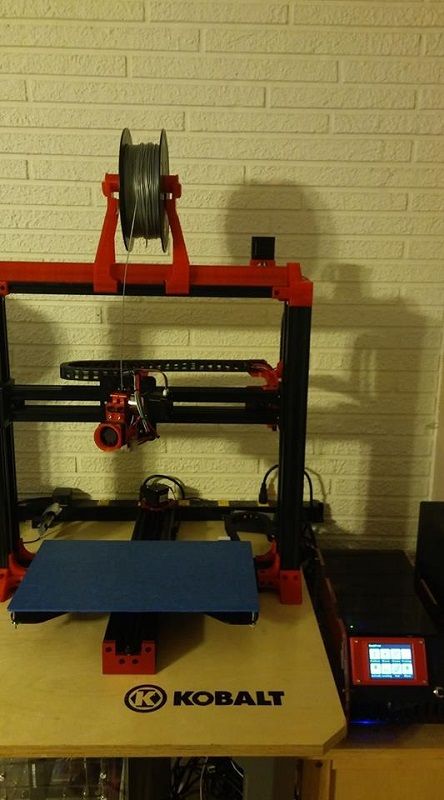

I have a lightweight titan extruder to setup and install but I still need some more pieces to make it complete. Like a volcano. So for the time, I am going to use the oem tevo extruder. But it is getting this bracket that hinges the extruder 15 degrees out..

before this modification the x axis was limited by the stepper motor on the extruder hitting the frame. This was as far as it would go before..

And with the 15 degree extruder mount the extruder can go all the way to the edge of the print bed..

front shots of the extruder..

And I used a length of the smaller drag chains I replaced for the y axis. So all moving wires are inside of drag chains..

Last edited by AutoWiz; 05-07-2017 at 06:26 PM.

-

05-07-2017, 06:25 PM #26

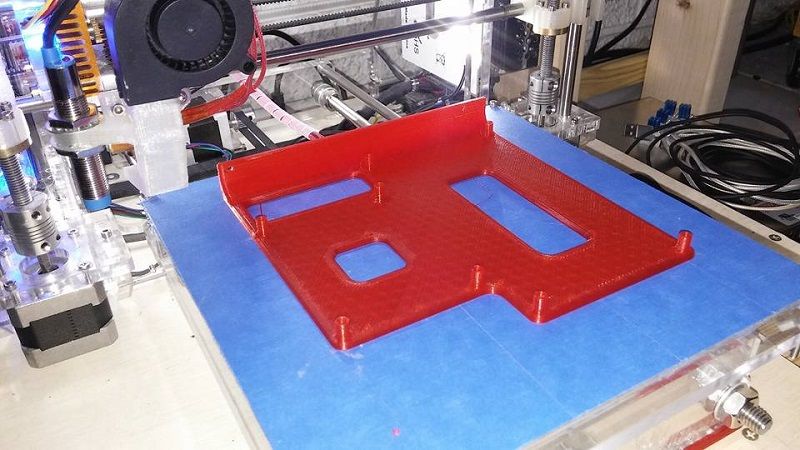

The last leg of this assembly here is the control box. I need to print out a larger control box that will house the better meanwell 600watt 24v power supply but none of my other printers are big enough so I have to put this together and then print the bigger case and then rebuild the control box. Tevo has had problems with their power supply/heatbed/control boards. And as such they have a few revisions of parts and they have added this external mosfet to control the heatbed but never added to the control box or instructions to provide for it's mounting so here I am..

The MKS gen board is supposed to bolt flush against the side wall of the control box. This mounting on it's own is a bad design because it orients the usb port facing straight down where you can't access it. here is the space and mounting holes I have to play with..

So I drew up this plate to hold both boards next to each other..

And now everything mounts neat and clean inside the control box..

...everything except for the wifi module I forgot about when I designed the plate. Oh well. It is only a temporary solution until I can print the bigger parts.

-

05-07-2017, 08:04 PM #27Engineer-in-Training

- Join Date

- Jan 2016

- Posts

- 326

AutoWiz, do you have access to auto repair manuals where you work? Do you have access to websites related to auto repairs and auto parts? I'm trying to create 3D models of cars but after looking through a few shop manuals, websites related to auto repair and auto parts, and plastic model cars that were already built, I can't create 3D models of auto parts that look like real auto parts, not toys. I tried to search the Internet for 2D and 3D drawings of auto parts but I couldn't do it.

-

05-07-2017, 08:47 PM #28

We use online shop databases such as Shopkey, Alldata, And/or Identifix. In these days where there are common and almost regular software updates for your car and regular service bullitens released with revised diagnostic and repair stratagies, I feel bad for any shop that relies on repair manuals. That died out by the early 2000's I think. But none of that matters for both the manuals and the online databases are chock full of information to aide in diagnostics and repair. Like listings of bolt torque specs. Written removal and install procedures with the occasional 2d poorly drawn reference image. Wiring diagrams. Technical Service Bullitens and Recalls. trouble code definition listings and diagnostic trouble trees. These are the things that automotive techs in the field need to accomplish our job. And none of it involves 3d modeled parts.

What you are looking for would be engineering. And Good Luck Getting your 3d rendered models of parts or cars from the manufacturers. This is something you are going to have to create on your own or I would imagine pay a ransom for.

-

05-08-2017, 05:42 PM #29

-

05-08-2017, 07:56 PM #30Student

- Join Date

- May 2017

- Posts

- 16

This build sponsored by Kobalt Tools

Looks great. what you going to build with it first?

Reply With Quote

Reply With Quote

Printing time- Is this right?

09-13-2024, 07:51 AM in General 3D Printing Discussion