Results 211 to 220 of 255

Hybrid View

-

02-15-2020, 11:57 AM #1Student

- Join Date

- Jul 2015

- Posts

- 27

Hell Printbus,

It's great to see you still have your 8" MF i3v running. This is the same model I have which I just dusted off last week and got her running again after almost four years. She still functions well. After becoming re-acquainted with it I immediately became a bit tired of Greg's accessible extruder. While the printer serves my purpose for now making small ABS parts, I started searching to see if anybody upgraded their MF with a newer extruder. Can you comment on your experience with your Bondtech BMG?

-

09-20-2015, 08:57 AM #2Student

- Join Date

- Sep 2015

- Posts

- 22

BobH2, thank you for great response. Although I normally would go the open source and free route, I think on this one I am going to jump the gun and go all out. After reading your response, I am convinced that it would better suit me. I would rather spend more money and make my first 3d experience as smooth as possible. Also would rather tinker with the printer and not worry as to what slicer works. All in all you pretty much convinced me to take the plunge and I think it is going to be worth it.after watching YouTube videos I definitely like seeing the model and the preview of it doing the prints. Pretty excited for my printer haha I can barely wait!

-

07-08-2016, 06:16 PM #3Engineer-in-Training

- Join Date

- Jul 2016

- Location

- Pennsylvania, USA

- Posts

- 255

Hi

Just to tag this into the "encyclopedia" ..... it's a great thread for anybody playing with an i3v.

The issue with the "old hot motors" was aggravated by the recommended settings being to high current. I pointed that out 3 years ago, it's still true today.

These printers slave two Z motors to one controller. That limits you to 1/2 the current rating of the controller on the Z axis. Most of the standard controller plugins max out at 2A. If you buy 2A motors you will only be able to run them at "half power" on the Z axis. With 1.5A motors you will get to 2/3 power. All that assumes you carefully adjust the trim pots on the controllers when you swap out the motors. My *guess* is that roughly 99% of the i3's out there (with slaved Z motors) are running half current on the Z relative to the X and Y.

All that said, yes, the old motors do get hot. Having plywood all around them or a heated bed over them ... they get warm.

Some Z axis math (not in my older post):

Most of time the Z does not move. It's just a load resistor. P = I^2 * R. Cut the current equally between two steppers and you cut the heat going into them by a factor of 4. Yes, they still get a bit warm. If you take a look at torque curves ... that drops off by quite a bit as current drops.

So why the "old recommendation for current" ?

If you set the current limits all the same and to ~ 0.2V, the X and Y work. The Z fails horribly. If you set it high with those motors, the 12V limits the current as a bit over max ... it all works, but gets hot. They *are* 0.5A steppers, the right setting on the controller is the 0.5A setting.

Yes, this is 3d printer archeology. It is mainly interesting to those with i3's that they might be upgrading to say an i3v. Unfortunately some *idiot* pointed out that the $50 rebate was still in place on the i3 -> i3v kit. It seems to now be history .... SORRY !!!!! That may make this information a bit less useful.

Bob

-

07-09-2016, 06:48 PM #4Engineer-in-Training

- Join Date

- Jul 2016

- Location

- Pennsylvania, USA

- Posts

- 255

Hi

The practical answer is that you can indeed run with much less than maximum torque out of the motors. You can fairly quickly calculate the step rate that inductance becomes more of an issue than resistance. At that point you may be off to 24V stepper supply land. I have never seen a need to run the steppers anywhere near that fast (24V supplies) on the Makerfarm designs. Dropping to a lower voltage stepper like the ones you switched to would make it even less of an issue.

Turns out that micro stepping really does not get you as insane with inductance as you might think. You *are* doing things faster. You are doing them at much lower current levels. Put another way, it's still a sine wave at the same base frequency. You just are defining it's phase it a bit more often.

Bob

-

01-03-2017, 12:28 AM #5Student

- Join Date

- Jan 2017

- Posts

- 7

I am new to the forum as well as 3d printing. A real rookie. But I do have a few things in my favor. I am truly a electronics geek. And am a very advanced kit builder of electronics and mechanical things. I have a touch of OCD that usually serves me well when assembling things.

I ordered my Makerfair i3v 8" Prusa last week and should have it in a few more days. I have been going over your incredible build thread/log. You have gave the community an awesome resource. I wanted to thank you for the time and effort you have put in to it.

Larry

I will be referring back to this thread along the way. I know my kit is newer so some info may not apply. I will figure it out as I go. Thanks again for putting this info all in one place!

-

02-02-2019, 12:37 PM #6

RASPBERRY PI AND OCTOPRINT

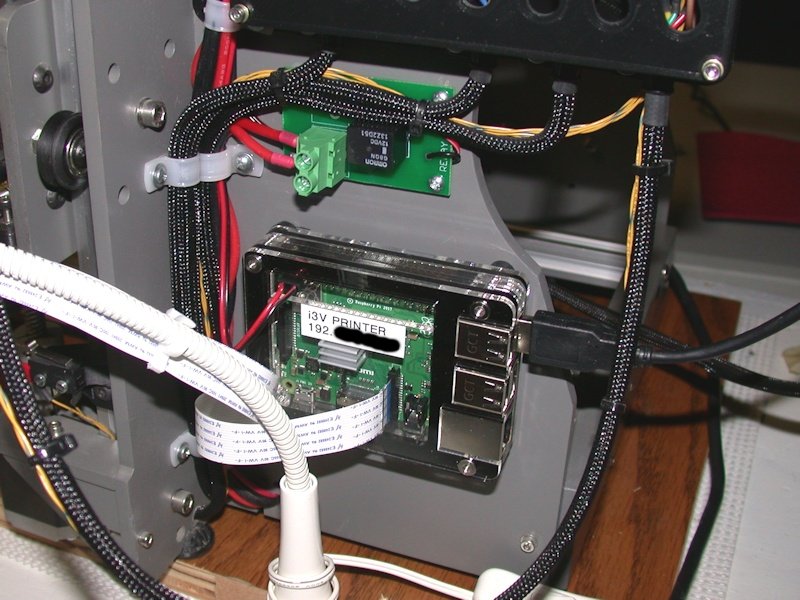

I've relegated the i3v to our unfinished basement, and opted to install a Raspberry Pi with Octoprint so I could control & monitor the printer from upstairs. The pi was mounted to the area I specifically left for it when I mounted the Smoothiboard case high-up on the right sidewall of the printer.

The Raspberry Pi 3B+ is loaded with Octopi and controlled either through the Octoprint web interface or through the Printoid app. In addition to controlling or monitoring the printer remotely, this also seems to have resolved the periodic issue I've always had with prints locking up when printing from Simplify3D connected to the printer via USB. Simplify3D continues to be declared incompatible by the smoothie developers because it isn't an open source product, so they could care less about the people reporting the lockup issues.

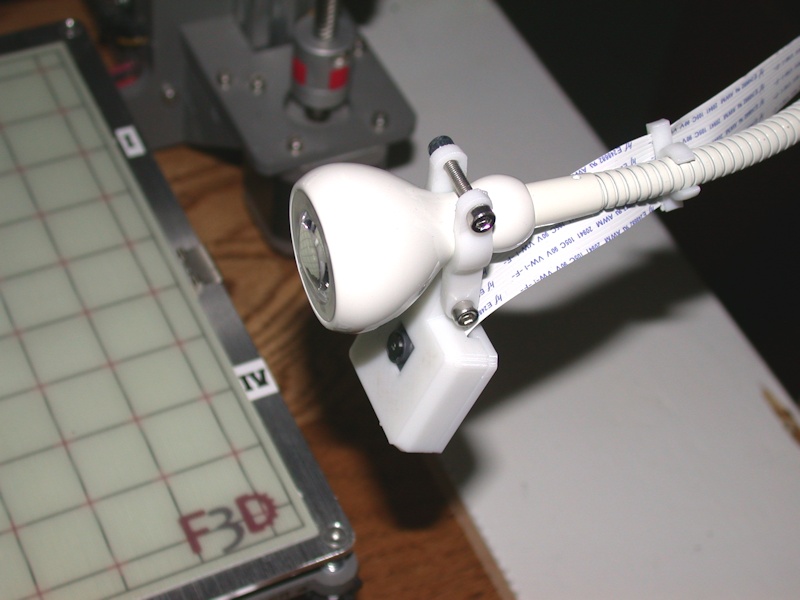

I wanted a small and basic camera to use with Octoprint, so I went with the Raspberry Pi camera module mounted to an IKEA Jansjo gooseneck LED lamp. The pivot clamp and the cable clips are available on Thingiverse at Raspberry Pi Camera System for IKEA Jansjo LED Lamp.

Adding the Raspberry Pi opened up questions on how I'd power the Raspberry Pi and the overall printer. After evaluating various options, I opted to power the Raspberry Pi from the 5V regulator I populated on the Smoothieboard for use with the LCD panel. With only the camera as a peripheral on the Pi, that 5V regulator should be able to handle the Pi 5V load as well. I added the original MakerFarm 30A relay in the dedicated wiring the Smoothieboard gets for the larger MOSFETs used for heater control. The relay is controlled through M80/M81 gcodes that I now add to my slicer output, and Smoothieware is configured to turn off the relay if it detects a temperature runaway condition or other fault.

AC power is controlled through Wink and a compatible smart plug that I already had. I realize there is a TP-Link compatible Octoprint plug-in that can be used for this, but for now I'm just using our existing Wink system.

In a nutshell, when AC power is turned on, the Smoothieboard logic, the Raspberry Pi, and the printer motors and fans all have power available to them. The heaters won't work until the additional relay is turned on.

-

02-01-2019, 04:48 PM #7

Thanks for this update. I still have the 8-inch rail version that I bought just prior to the release of the i3v. It's still working great and I use mine pretty much the same as you, now and then, and often big lapses of time goes by. It still prints very clean and beautiful parts. I've made a few upgrades as well. One is a "leveler" that I posted on this site and get 4 or 5 downloads a month. The other was a dial head design called the Itty Bitty (designed by @Clough42). Like you, I print only one material, but I use PET.

I'm glad to see your iv3 is still going strong.Bambu P1S/AMS

NVision4D http://nvision4d.com

-

02-02-2019, 07:24 PM #8

Dialogue with RobH2 has made me wonder and go look at my Thingiverse data. Across the 33 or 34 designs I've bothered to post there, the most "popular" as far as downloads is my take on a parametric shaft collar, with a thousand or so downloads.

A close second is my hinged Graphic LCD mount for the i3v.

Now that Thingiverse has a way for users to tip designers, the money has been flowing in. To date, I've earned a grand total, after significant PayPal fees of course, of $1.34 USD.

Most of my Thingiverse pool is stuff where I started with someone else's Thingiverse design and refined it or adapted it, reposting the update back to Thingiverse due to attribution or other requirements of the license assigned to the design by the originator. I do have other designs that aren't on Thingiverse, as more posts here will soon show.Last edited by printbus; 02-02-2019 at 07:32 PM. Reason: clarity on the licensing

-

02-01-2019, 06:34 PM #9

Yea, I too wonder how many machines Colin has shipped. He's the best Customer Service on the planet. I wish my cable company was as nice...

45,000 downloads is a lot. Wow. Anything I've ever posted was pretty specific and had little attention. The simple leveler I mentioned was pretty handy. People download it but I never hear if they liked it. I guess if not I'd be getting mean emails and I've never had one.

Good to see you again too. I originally got into 3d printing to build drones. Then I bought an Inspire 2, and then a Mavic 2 Pro. All of a sudden, I didn't need my 3d printer for making drones and I've gotten less visibly active here. I'm still here helping out but I spend most of my time deleting spam and answering direct questions.

I did print some parts recently for my Inspire 2. The good old Makerfarm made perfect parts for me and never skipped a beat.

Carry on...Bambu P1S/AMS

NVision4D http://nvision4d.com

-

02-02-2019, 07:00 PM #10

It isn't the part I saw that was unique to the Ender 3, but here's a Thingiverse cooling duct with downloads in the hundreds of thousands. That kind of traffic has to almost be annoying in one's Thingiverse dashboard.

It's sort of funny that you mention that. RC helicopters was a major reason for my interest in 3D printing. I was new to the hobby, and another user in the Helifreak 130x forum promised to start cranking out designs for 130x parts. I remember describing to the wife all the money I'd save by printing my own replacement parts. Unfortunately, he, I, and the rest of the 130x community grew to realize that the strength-to-weight ratio just wasn't going to be there for 130x parts. I migrated to a larger 300x for a while, but never gave printing parts for it a thought for the same reason....I originally got into 3d printing to build drones.

I did delve into drones a bit before I pretty much gave up on my old eyes ever doing well with keeping the orientation straight. I do have a 105mm quad FPV frame on Thingiverse. Turned out a bit heavier than I was hoping for, but it made for a pretty good back-yard basher.

Reply With Quote

Reply With Quote

Please explain to me how to...

05-17-2024, 12:15 PM in 3D Printer Parts, Filament & Materials