Results 1 to 10 of 132

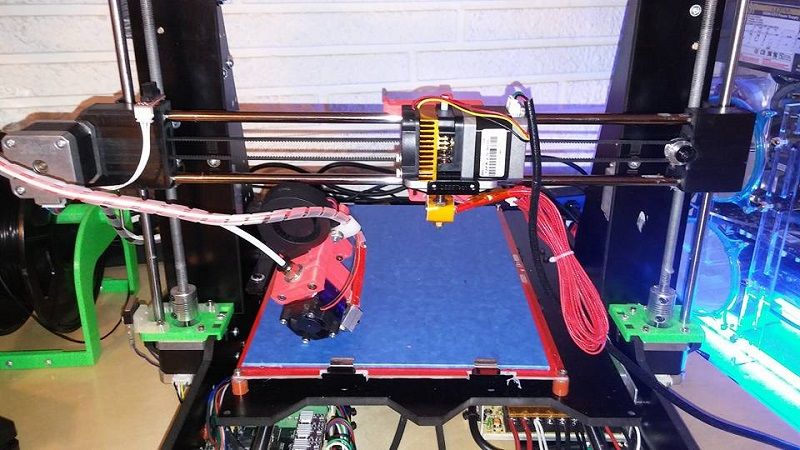

Thread: My 3 Color Mixing Printer

Hybrid View

-

12-23-2016, 07:51 PM #1

Well, The e3d v6 hotend solved the jamming issue. But I am now having this other issue. The printer seems to be doing it's job right, that is all axes are tight with no freeplay anywhere. with the belts off x and y move smoothly and freely. And my supports have stopped the creaking of the frame. But now my printer is doing this..

So I reprinted this a bunch of times making adjustments to the temp and extruder steps per mm..

I went as high as 5120 and as low as 3620 without correcting the problem. And it is a lot of steps per mm by design. I have drv8825 1/32 stepping driver boards and a gear reduction wade extruder. In the beginning of all this I thought I was chasing high precision. so the more steps for a given distance of movement the better. I must now believe my problem lies either with the wade extruder, its calibrations / settings, or the ptfe tubing (maybe too long?) So in anticipation of less than stellar performance from this setup, I have already ordered and received a mk8 extruder identical to what came on my geeetech prusa i3 that has been a workhorse for me. So we gotta swap some more parts on the printer..

I am keeping all these hotends and extruders and parts and as soon as I establish a reliable good quality printing machine, I will work my way back to some of the features I have steered away from.

Reply With Quote

Reply With Quote

Please explain to me how to...

Yesterday, 12:15 PM in 3D Printer Parts, Filament & Materials