Results 301 to 310 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

02-26-2016, 12:47 PM #301

-

02-26-2016, 12:54 PM #302

Get a hold of Qidi Tech and they will send you a whole new extruder Assy.

Take pictures of the extruder and the front of the machine to prove you have an old setup.

Look at the long aluminum bar that the exteruders attach too are there 2 tapped holes on the left end of it?

Sounds like your having adhesion problems.

Find a Youtube video on leveling the build plate and recheck it.

I usually run my glass build plate at 60c.

My printers are in the basement which is pretty cool so I make sure that inside the cabinet is at least 70F.

I have digital thermometers inside my printers to monitor the cabinet temperature.

-

02-26-2016, 01:01 PM #303Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

I can, both raise and lower the platform to max limit by hand just like Qidi says you should be able to.

The cable bunch that comes from heat plate was somewhat loose in the board connection. Pushed that all back tight and about to plug it in again.

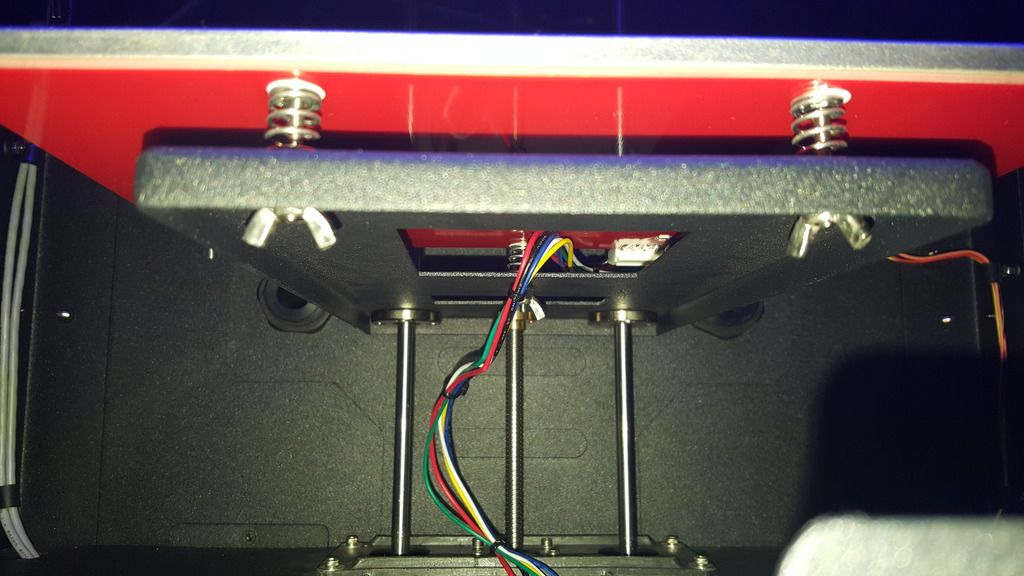

If anything is bent it seems like the metal bracket the heat plate mounts to.

-

02-26-2016, 01:13 PM #304

-

02-26-2016, 02:04 PM #305Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

-

02-26-2016, 02:19 PM #306

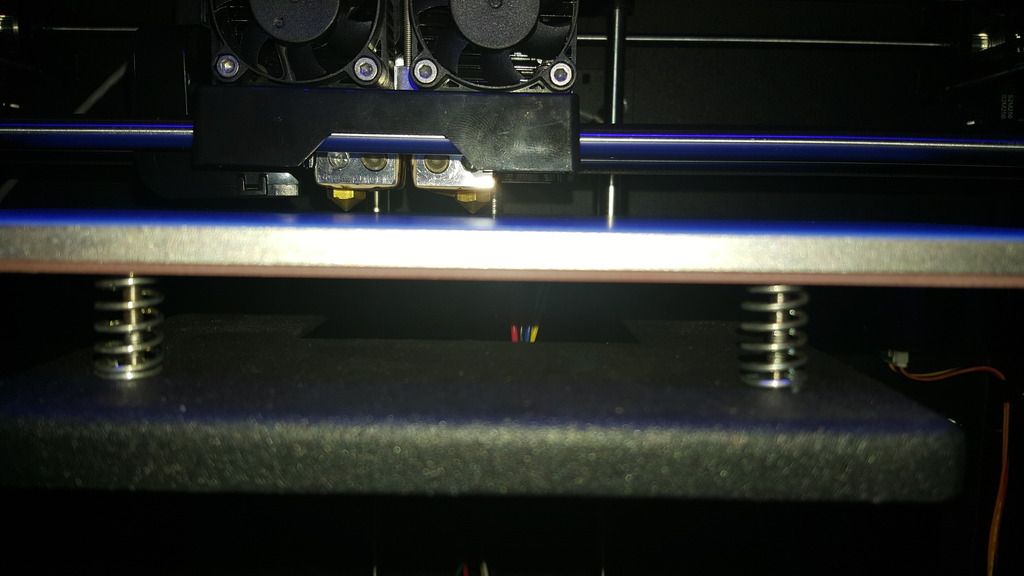

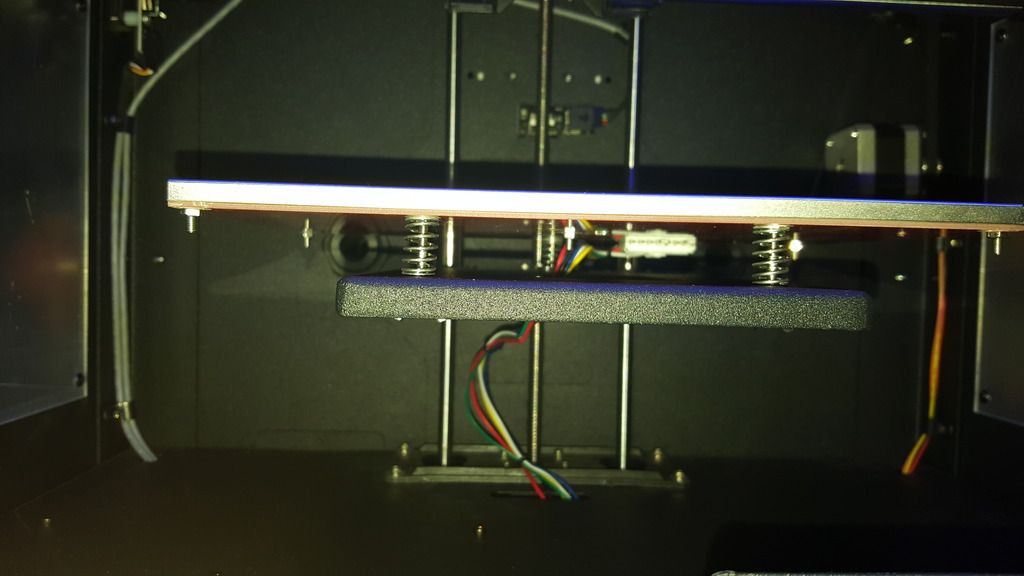

How about a picture showing the build plate up to the limit switch.. With the extruders centered on the build plate.

I want to see what the gap looks like.

The printer is sitting level right?

You can remove the build plate to get a better look at the support.

-

02-26-2016, 02:47 PM #307Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

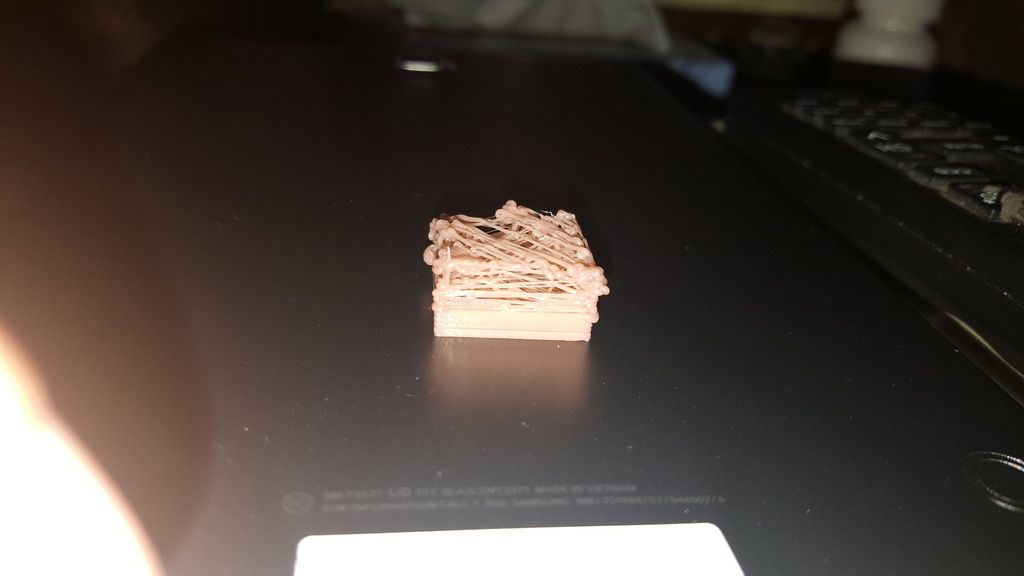

Gap in middle of printplate

Gap in center front of plate

I can not get the plate any higher than this in the front, the 2 bolts are out of thread.

I did manage to get something to print, was supposed to be a 20mm test block. The bottom few layers printed very well, then it left a few gaps, then about half way up it stop printing the exterior structure all together.

edit:

To clarify, the gap at full center of the plate is about double what it should be. The gap in front center is 3-4 times what it should be. Only using right extruder at the moment.

-

02-26-2016, 02:59 PM #308

If the printer itself is level on a level surface you could take the build plate off and put a small level across the build plate supports to see if they are level. Otherwise I'm not sure I would have to take the extruder Assy out and check the hot block heights are even.

-

02-26-2016, 04:27 PM #309Technician

- Join Date

- Jan 2016

- Posts

- 81

-

02-26-2016, 08:06 PM #310Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

Made alot of progress today.

Have my machine set back up where its supposed to be.

It was not printing because the plug for the heatplate was loose in the motherboard plugin. Now its showing the proper temp, and heating/cooling like it should.

I still cant totally level the plate, but I'm fairly sure its an issue with the mount. However I can get the back 1/2 of the buildplate very level with the gap Qidi recommends. I am going to try and print(just on back 1/2 of the plate) the bracket/shim I need to mount the glass. I am going to take 2mm height off of the shim. This will make the plate 2mm higher and should solve this last little issue I'm having.

Just want to thank everyone again for all the help, you all awesome!

edit:

Anyone have a vid on how to install a z axis shim on this machine. Looked around a bit and not getting a clear explination.Last edited by Syd_Khaos; 02-26-2016 at 09:31 PM.

Reply With Quote

Reply With Quote

Ender 3 Neo - Jam Problem

05-08-2024, 03:06 PM in Tips, Tricks and Tech Help