Results 2,361 to 2,370 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

Hybrid View

-

08-19-2016, 08:39 AM #1Technician

- Join Date

- May 2016

- Posts

- 55

I've been using Slic3r with a lot of success, after initially using ReplicatorG. The only issue is that I had to completely set up the software myself, but that wasn't too difficult. I modified the G-code for Simplify3D to use Slic3r's variables, then looked at the G-code Slic3r produced and removed some redundancy. I copied what settings I could from the RepicatorG preset as a starting point and tweaked from there.

I'm only use G-code for using both extruders. I've created a filament profile called "none" that I use for the extruder I'm not using, It seems to work well.Last edited by JSensebe; 08-19-2016 at 10:30 AM.

-

08-19-2016, 01:22 PM #2Student

- Join Date

- Aug 2016

- Posts

- 11

I know DaveB has seen this but have the rest of you seen the FlashForge Creator Pro Turbo video with all the upgrades he did on Thingiverse? http://www.thingiverse.com/thing:1681920

I especially love the external blower with injected cooling - I would love to do that and ditch the fans and show off the Flexion extruders but not really sure where to start...

-

08-19-2016, 01:38 PM #3

Thermocouple shouldn't affect blocks or height.

Ya depending on the heater and thermocouple position there could be some differences in readings. That is just bad heater block design. That's why my heater blocks are compact and the nozzle and heating element are very close together.

-

08-19-2016, 01:43 PM #4Student

- Join Date

- Aug 2016

- Posts

- 11

-

08-19-2016, 01:55 PM #5

I don't wrap them, since the overall heater block is smaller there is less heat dwell from the block and this helps plastic cooling. One of the reasons blocks are wrapped is heat dwell. Where the heater block is so big and hot it can actually melt the plastic from radiated heat or at least keep it softer than it should be.

But you can wrap them if you want.

-

08-19-2016, 02:13 PM #6Student

- Join Date

- Aug 2016

- Posts

- 11

-

08-19-2016, 02:27 PM #7Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

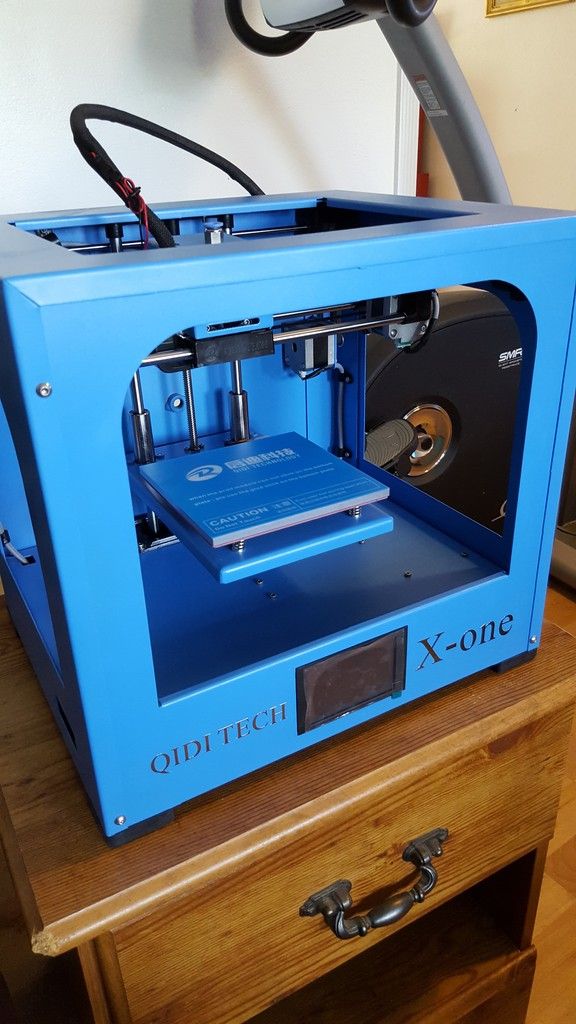

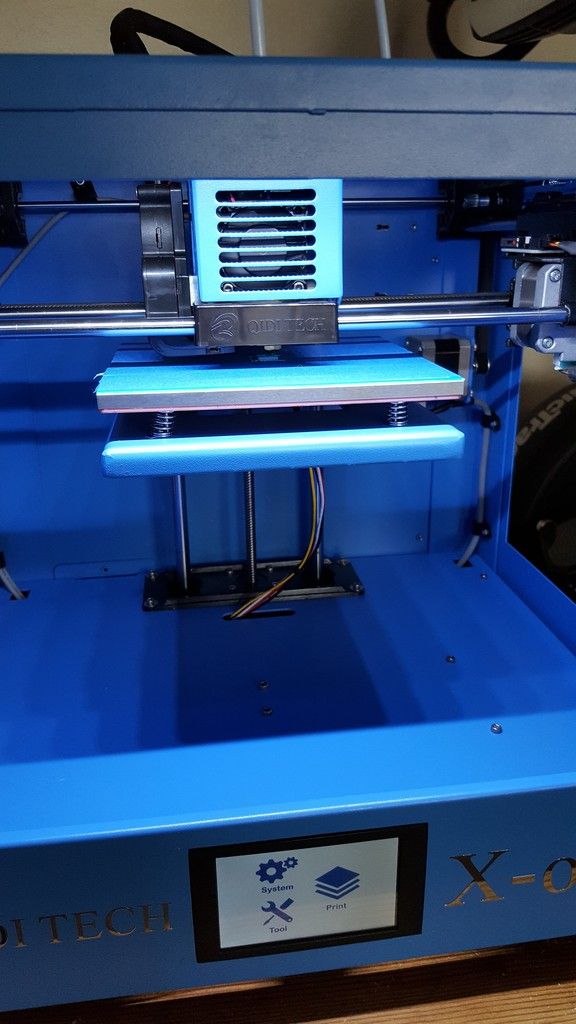

OK!! The new QIDI X-ONE.

I have a bunch of parts that are well within the size of this one. Load them up and let it go. They had a good introductory price and shipped free from the USA.

The software I think is a version from Cura. Pretty good to get going with.

Set up was not a big deal and printer was packed excellent.

First print is their test "cube" pillar. 1mm X 1mm X 50mm and the size is almost dead on.

[IMG] [/IMG][IMG]

[/IMG][IMG] [/IMG][IMG]

[/IMG][IMG] [/IMG]

[/IMG]

-

08-19-2016, 03:23 PM #8Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

All right W! I guess you qualify as a true "blue" QiDi user. <grin> From now on I guess we will have to specify which QiDi printer model is being discussed. I like the look of the control panel. From your pix it looks to be the same basic drive design. Does it use 8mm or 10mm rods for x, y & z?

-

08-19-2016, 03:45 PM #9Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

It all looks to be a narrower (X-axis), single extruder version. Otherwise everything really looks the same. Rod sizes are the same.

So far it is printing nice. This could be a good one for just doing those jobs and don't mess with the printer to much, just let it run. This looks like it could be a great starter printer that is fairly straight forward but still high quality. We will see over time but so far it is delivering.

The software is definitely usable and with a fair amount of control.

I have been in contact with S3D and QIDI who said they were going to get with S3D. No sooner did I tell the guy at S3D he emailed back and said they (QIDI) had just gotten a hold of them about the printer. S3D is excited to work with it and get things rolling so support from both so far has been great.

-

08-19-2016, 04:00 PM #10Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

Reply With Quote

Reply With Quote

Please explain to me how to...

05-17-2024, 12:15 PM in 3D Printer Parts, Filament & Materials