Results 111 to 120 of 189

Thread: Show your MODS

-

11-28-2014, 08:43 PM #111

It's a dual hexagon extruder. I respect the decision to concentrate on one system rather than trying to be all things to all people.

I would be a bit careful on the brand new stuff from E3d for a while since they stepped on their ding a lings pretty good with the Phoenix printer deal.

-

11-28-2014, 09:13 PM #112Engineer

- Join Date

- Jul 2014

- Location

- Eastern Colorado

- Posts

- 536

It's a dual extruder for anything you can get to fit the spacing. If the new dual hotends fit, I see no reason to not use them.

-

11-30-2014, 10:14 AM #113Engineer

- Join Date

- Jul 2014

- Location

- Eastern Colorado

- Posts

- 536

For those of you who are not using Auto Bed Leveling yet, here is a caliper holder I made for the i3v. http://www.thingiverse.com/thing:570778 It clips onto the X axis v-slot extrusions, and lets you use the caliper's depth gauge to level the print bed.

Please excuse the ugly filament. I'm trying to use it up as fast as I can, and usually paint it to hide it.

-

12-01-2014, 07:47 PM #114

Agreed.

I think the hot ends you mention, though are for bowden use. While you could use my extruder to drive a dual bowden system, it wasn't really designed for that. There are probably better options.

The Itty Bitty Dual Extruder is really all about getting the hot ends as close to each other as possible and minimizing moving mass. Neither of these are issues for the bowden.

-

12-02-2014, 05:18 PM #115Student

- Join Date

- Dec 2014

- Posts

- 3

Very cool thread. I ordered a i3v 10" last weekend and am hoping I can get most of Clough42's mods to work for it as I am new to the 3d printing world. Thanks for all the hard work guys

-

12-03-2014, 08:48 PM #116Engineer

- Join Date

- Jul 2014

- Location

- Eastern Colorado

- Posts

- 536

-

01-13-2015, 12:48 AM #117Engineer

- Join Date

- Dec 2014

- Location

- Canada

- Posts

- 498

Here is my first custom mod for the i3v

http://www.thingiverse.com/thing:633186

-

01-13-2015, 10:50 AM #118

-

01-13-2015, 11:15 AM #119Engineer

- Join Date

- Dec 2014

- Location

- Canada

- Posts

- 498

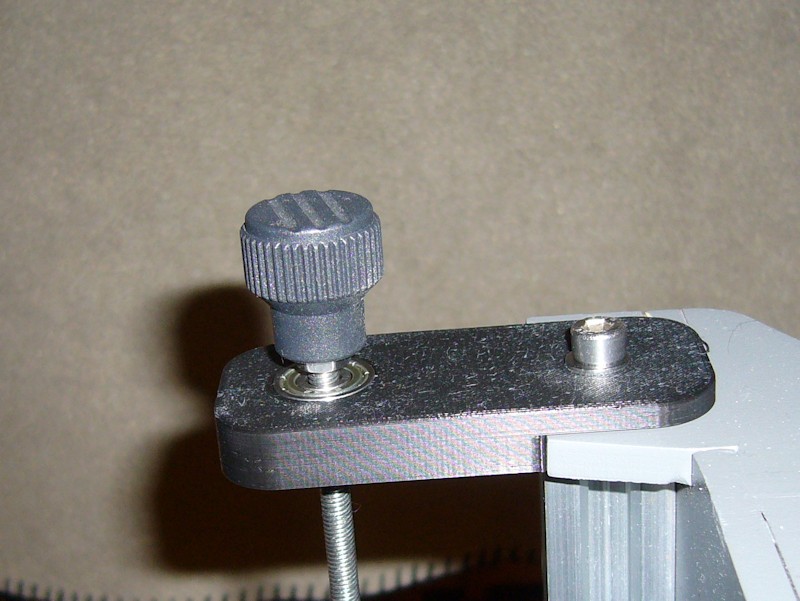

Like this

-

01-15-2015, 04:22 PM #120

Z-ROD SUPPORT BRACKET

I've published an improved support bracket for use at the top of the i3v frames to Thingiverse - http://www.thingiverse.com/thing:636381. There's been another bracket out there, but I found ways to improve various aspects of it. Predefined STL files with and without a bearing recess are provided, along with the openSCAD source that allows the entire bracket to be customized.

The same bracket would be installed on both sides; I don't offer one that includes mounting provisions for the MakerFarm spool mount.

These won't improve print quality. In fact, if they're installed with pre-exisiting bent threaded rods, print quality might actually suffer since any bend may force the X carriage to wobble around a bit as the bent threaded rod is rotated. The brackets are intended to help prevent straight threaded rods from getting bent. In my case, I've been on borrowed time before our grand daughter grabbed one of the rods and bent it over.

Last edited by printbus; 05-29-2015 at 11:37 AM. Reason: migrated to offsite image storage due to 3DPrintBoard issues

Reply With Quote

Reply With Quote

Kickstarter campaing LEGENDARY...

Today, 08:02 AM in Free Self Promotion