Results 371 to 380 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

03-01-2016, 08:31 AM #371Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

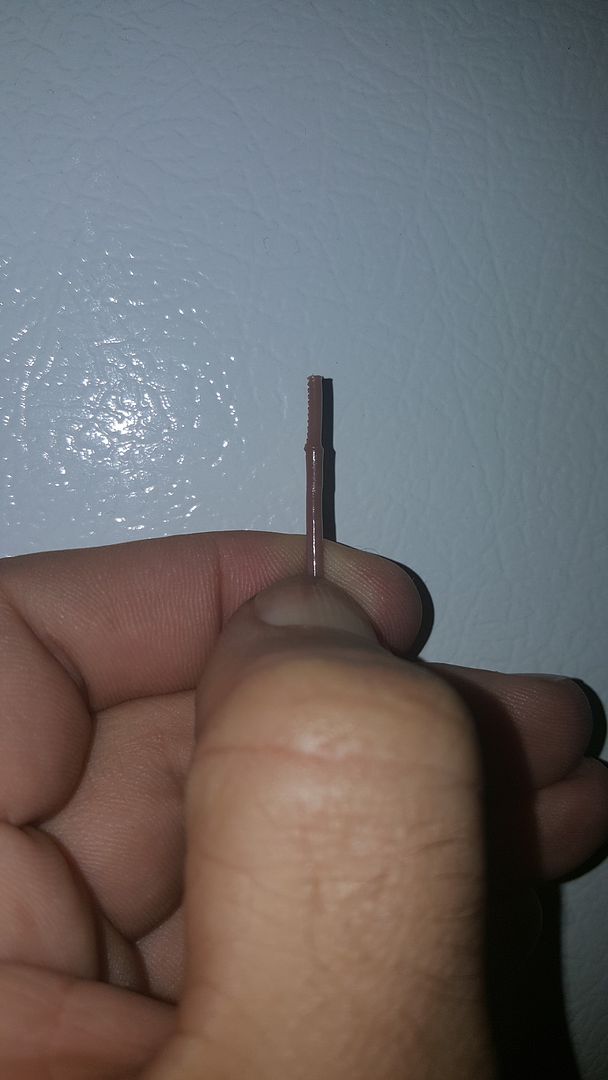

Well thurs yer problem!

To small to hit the toothed feed gear or the heat. The little swelled bit was caught up on the smooth feed wheel.

So now I am ready to put the machine back together. Go out to garage and grab my torch cleaning needles.....wouldn't ya know the .4 and .3 needles are missing.

Its fast becoming one of those 'I should have stayed in bed' kinda days =P

-

03-01-2016, 10:33 AM #372

I fix and support high tech stuff for a living and have a lot of those kinda days.

Glad you found it but get use to taking the extruders apart because this won't be the last time.

Stands as a reminder 3D Printers aren't a regular household appliance and require frequent maintenance.

-

03-01-2016, 01:30 PM #373Student

- Join Date

- Feb 2016

- Posts

- 6

Thanks guys, the Aquanet+glass is doing the trick!

has anyone had to mess with the steps per mm on this machine? my x axis seems 0.15% undersized and the z axis 0.3% undersized. the Y seems spot on and I didn't check the extruders. it looks like the only place to change this is in the x3g tab of S3D. has anyone had to make similar adjustments?

-

03-01-2016, 01:38 PM #374

I've not noticed mine being off. What kind of plastic are you printing with.

-

03-01-2016, 03:17 PM #375Student

- Join Date

- Feb 2016

- Posts

- 6

ABS. definitely have some over extraction issues. trying 0.9 extrusion multiplier now. but I got those numbers using a caliper to the machine, not from measuring a print.

-

03-01-2016, 03:31 PM #376

Have you printed a 20 or 40mm calibration cube?

If so do the measurements come in close?

If they do your good.

-

03-01-2016, 04:33 PM #377Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

I'm certainly no stranger to tinkering. Me and a buddy even made fully drivable hovering barstool.

I'm just a cautious of tearing into something I have no clue about. The trolly system is a no brainer, but up till this morning I had very little idea what was going on in the extruder assembly.

Ended up having to use compressed air to blow the nozzles clean. Gonna run up to music shop and get right sized string and make some cleaners.

Running my first print now with the Orb Polymer materials...will let yall know whats up with the quality.

Did you ever print with that stuff from MakerGeeks.com? If so how did it compare?

edit:

What would cause the machine to play its tones mid-print?

Printing some PeTG right now, so running rather hot. Machine keep playing its little music.Last edited by Syd_Khaos; 03-01-2016 at 04:52 PM.

-

03-01-2016, 09:29 PM #378Technician

- Join Date

- Jan 2016

- Posts

- 81

-

03-02-2016, 02:46 AM #379Student

- Join Date

- Feb 2016

- Posts

- 10

Hi all I finally got my printer after customs held it for days and then charged import tax (damn strict NZ customs). I have new firmware 7.8 and 2560 chip. It came with the blower fan which was easy to install. It came with gold ABS and yellow PLA. I have a clicking sound on the Y axis somewhere that I need to track down, possibly just a zip tie rubbing.

It is printing ABS really nicely at 0.2mm layer height. I tried print at 0.4mm layer height and it wasn't so good, probably need to tweak some other settings? I'm using MakerBot software at the moment as I need to save some pennies to get S3D.

I'm in the process of trying to make some custom corner clips for glass I have from my old printer that is 200mm x 215mm. I will get new glass correct size but this is a short term fix. I've made about 3 sets and have to keep adjusting dimensions to get it to fit correctly.

@rcleav You mentioned you are using AstroPrint to monitor your prints. What camera are you using? Does the video work? I have an rPi ribbon camera attached and I can take stills but not see a live streaming video. Is there any setup required on AstroBox besides enabling camera via raspi-config?

IMG_20160301_190437.jpgIMG_20160302_214448.jpgIMG_20160301_181852.jpg

-

03-02-2016, 06:36 AM #380Technician

- Join Date

- Jan 2016

- Posts

- 81

.4mm is not suggested for a machine with a .4mm nozzle. You shouldn't try going over .3mm. If you go .4 it will have some serious issues with lay adhesion and the layers will split. has something to do with not being able to push pout enough material to fully contact the previous layer without cooling too much first.

Reply With Quote

Reply With Quote

Ender 3 Neo - Jam Problem

05-08-2024, 03:06 PM in Tips, Tricks and Tech Help