Results 1 to 10 of 255

Hybrid View

-

06-05-2014, 11:16 AM #1Technician

- Join Date

- Apr 2014

- Posts

- 50

This is the most ridiculously anal-retentive build of a Makerfarm Prusa 8" i3v I've ever seen...

...AND I ABSOLUTELY LOVE IT!

-

06-05-2014, 02:34 PM #2

Thanks. Admittedly, the ridiculously anal-retentive build required quite a time investment. While it's possible no one else will replicate the full effort, it should at least offer ideas that people can incorporate into their own i3v repairs or new builds. The build does show that with effort, you can get whatever level of product refinement you want out of the i3v.

I'm still working through some issues that I want to resolve before I post my final build comments. I'm also waiting on a replacement stepper motor driver, and my spare time has to soon shift to preparing for a private July 4th fireworks show. It may be a while before I give the printer a serious workout.Last edited by printbus; 06-05-2014 at 03:00 PM.

-

06-06-2014, 01:15 AM #3

-

07-31-2014, 01:19 PM #4

SIX WEEK STATUS UPDATE

After about five dozen prints, I'm still content with my decision to go with the i3v. Primarily thanks to Thingiverse, I've pretty much got the hardware where I want it to be for now...

SLICER

After futzing and researching, I've opted to focus on Cura as my slicer. Working with both v0.9.9 and v1.1.6 in Slic3r, I just grew increasingly frustrated with gcode conversion taking so long or not completing, with some prints having gaps left behind while on other prints excessive time seemed to be spent on gap/hole touchup, with nozzle moves that do not follow logic, with some prints coming out better in v0.9.9 while others did better in v1.1.6, and with support capability still being somewhat lacking. Some of these issues may be user error in dealing with the 100+ settings in Slic3r, and at some point I may want that detail of control back, but for now I'm doing great with the subset of controls Cura provides.

FOLLOWUP COMMENT: When Repetier baselined Cura as an integrated slicer, I migrated to that. I'm liking it. It provides a nice interface that integrates printer manual control, slicing, layer by layer review of the slicing result, printing, and layer-by-layer monitoring of what the printer is doing.

PRINT SURFACE

With the hairspray-on-glass surface I had been using, I battled getting the first layer of PLA to stick with Cura. At all. Research indicated others have also had first-layer problems when switching to Cura. Changing pertinent settings and moving to printing on blue painter's tape with no heat applied helped, but not enough. For me, the magic combination seemed to be the settings and blue tape, along with wiping the painter's tape down with isopropyl alcohol after installing it and then adjusting the nozzle clearance with the nozzle hot. I wasn't expecting to have to re-engineer the first layer approach just because I went to a different slicer. There's definitely a difference in how the first layer is handled.

LEVERAGING THINGIVERSE AND OTHER MODS

So far, I'm not into designing my own stuff to print. I'm busy enough with just figuring out the printing side of things. Here are the things I've incorporated into the i3v...

I swapped out the original thumbwheels under the heat bed with ones that have more knurl - http://www.thingiverse.com/thing:29782. The one at the rear left corner was filed down just a bit to clear the frame side wall. To recap, on my printer all four corners of the heat bed are adjustable. Screws are locked to the heat bed, and the thumbwheels go under the Y-bed. It takes about a minute for me to check and adjust level around the bed. I'm currently seeing no issues driving me to incorporate automatic bed leveling.

FOLLOWUP COMMENT: A side benefit to these thumbwheels is that they have 10 ridges around the circumference. At 0.5mm pitch on the M3 screw they are mounted on, each notch in rotation equates to a 0.05mm height adjustment in that corner.

I swapped out the LCD knob with one that just looked better - http://www.thingiverse.com/thing:385882

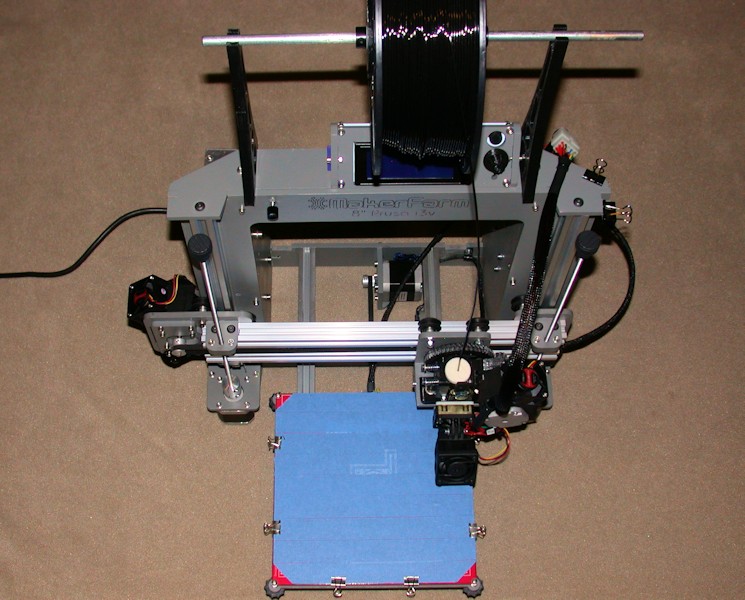

For a spool mount, I migrated to brackets that hold the spool directly above the top plate on the i3/i3v - http://www.thingiverse.com/thing:192510. There are multiple bracket designs that hang the spool to the rear, but I didn't like the idea of that weight putting torque on the top plate. The spool I have from MakerFarm with 1.5-inch spindle got a pair of these hubs with bearings - http://www.thingiverse.com/thing:7853. My other spools with dual-size spindles use prints derived from http://www.thingiverse.com/thing:28046.

FOLLOWUP COMMENT: I found there's a side benefit to the spool being on a wide rod. I ended up with shaft collars on each side of the spool, and the shaft collars are tightened to the rod. I can adjust the spacing of the shaft collars to put just a bit of drag on the spool. This has been really helpful in keeping the windings on the spool layered properly. I found that if the spool spins too freely, the spool can start to unwind itself and loosen up several turns of filament. This could eventually lead to feed issues.

It's not Thingiversed, but I now print the cooling shroud for the hex hot end in ABS so I can easily cut out the bottom of it to clear the nozzle body of the hot end. Whose idea was it to have the printed cooling shroud snap onto the hot end and rest on the aluminum block where, um, PLA and ABS gets melted? I added some kapton tape to the top surface of the hot end block to help insulate the block from the hex cooling fan airflow. I also swapped out the noisy hot end fan MakerFarm with a quieter one. The first one was around 5 CFM but super quiet. This was OK with PLA, but the extruder base started getting soft when I started working with the higher temperatures of ABS. The current fan is only spec'd at about 6 CFM, but has a higher speed that can probably do better at pulling air through the shroud.

FOLLOWUP COMMENT: I later added wings to the rear of the shroud to ensure airflow is forced onto the hot end heatsink. See EXTRUDER REBUILD AND NEW PRINT COOLER (Part 1).

In the original build, I futzed with the X and Y idler alignment so that belts wouldn't drift to the side and rub against the wood of the mounting brackets. I no longer had a problem to solve, but as a design improvement I printed and installed a pair of these belt guides - http://www.thingiverse.com/thing:359773. I installed them with three washers - one on each side and one used as a spacer between the two bearings that press into the belt guides. The belt lengths needed to be increased a few teeth, but I had left enough excess length before to cover this.

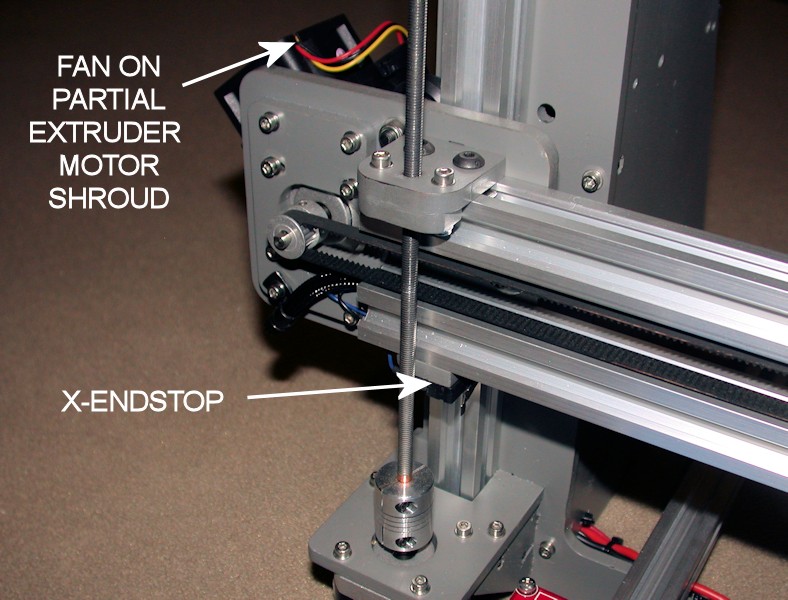

Clough42 has a pretty slick cooling shroud for adding a 40mm cooling fan to the extruder motor - http://www.thingiverse.com/thing:343026. I'm using a fan that doesn't put through the air that the one in his Thingiverse picture does, but I used what I could find locally and wanted to lean towards the quiet side as a starting point. Rather than cover some of the motor metal with a zip tie to strap on the shroud, I used a loop of solid wire as an attachment in addition to the snug fit the shroud already has on the motor. While the design is great, as a non-expert I found it to be one of my more challenging prints to date. Six or eight attempts ended up in the trash. One, the grid that faces the motor appears to not show up until the second layer (although I did get some gcode from Slic3r 0.9.9 that included it in the first layer), and many prints would start out bad because of this. Two, one side of the shroud has a pretty good slope to it that I found challenging. Three, I'd typically end up grinding into the filament when the end was near and I'd only be adding small layers to the "uprights" in the print structure. I'm sure the latter issues were my own doing - especially my retraction settings. I printed another after getting Cura somewhat figured out and a print cooler installed - that print turned out far better, first shot.

FOLLOWUP COMMENT: I have the motor type that runs hot. A cooling fan for the extruder stepper motor may not be required by all MakerFarm kits.

FOLLOWUP COMMENT #2: In EXTRUDER REBUILD AND NEW PRINT COOLER (Part 1), I ultimately replace the hot-running motor with a different one.

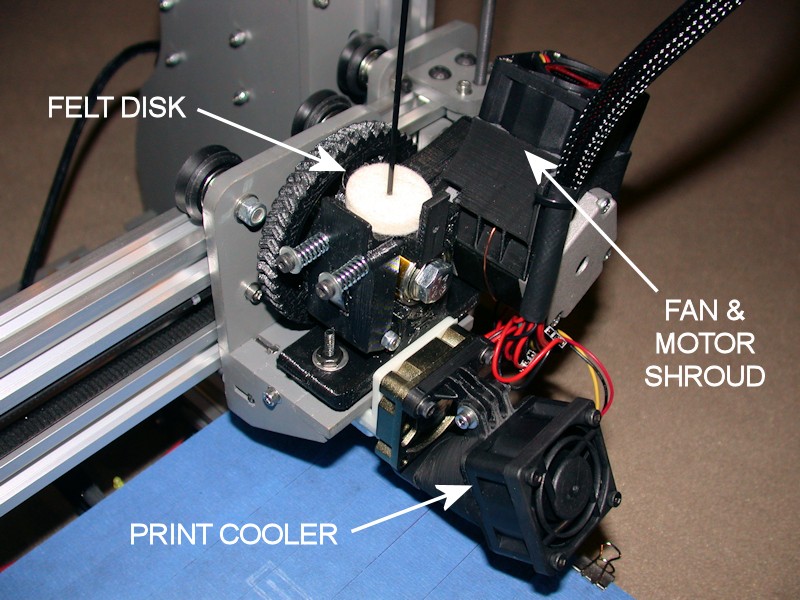

Filament now passes through a Dremel "felt polishing wheel" added to the top of the extruder to wipe the filament clean. This was added after I found the need to unroll quite a length of filament to remove some twists showing up towards the end of a spool of white filament. Enough of the filament was unrolled that it ended up on the floor. My print area has black and dark grey commercial carpet, and we have two black cats and a small dog with short black hair that hang out in the same area. Need I say more?

I've incorporated Clough42's print cooler - http://www.thingiverse.com/thing:351280. It fits best without the stock hex hot end cooling shroud and fan in place, but my glued-together X-carriage and undermounted LED lighting doesn't lend to incorporating his alternate hex hot end cooling system, and I'm not sure the alternate system will handle cooling for ABS. I just mounted it in addition to the hot end shroud and fan, and I've been playing with extending the print cooling shroud with large heatshrink. My PLA prints are definitely coming out better with this. I tried a couple different fans, and ended up sticking with an Adda fan with 10 CFM at 7800 RPM. The lower RPM isn't too obnoxious at full speed, even though the speed can usually be dialed back either via the slicer setup, LCD, or Pronterface/Repetier Host type software.

FOLLOWUP COMMENT: I've since removed the print cooler. Mounted on top of the hex hot end fan, it was likely blocking some of the hot end fan airflow. Combined with the low-flow fan I had on the hot end, this allowed the extruder base to soften up when I started printing at higher temps for ABS. So, I removed the print cooler and also put a stronger fan on the hex hot end.

FOLLOWUP COMMENT #2: The new print cooler approach is discussed in EXTRUDER REBUILD AND NEW PRINT COOLER (Part 2).

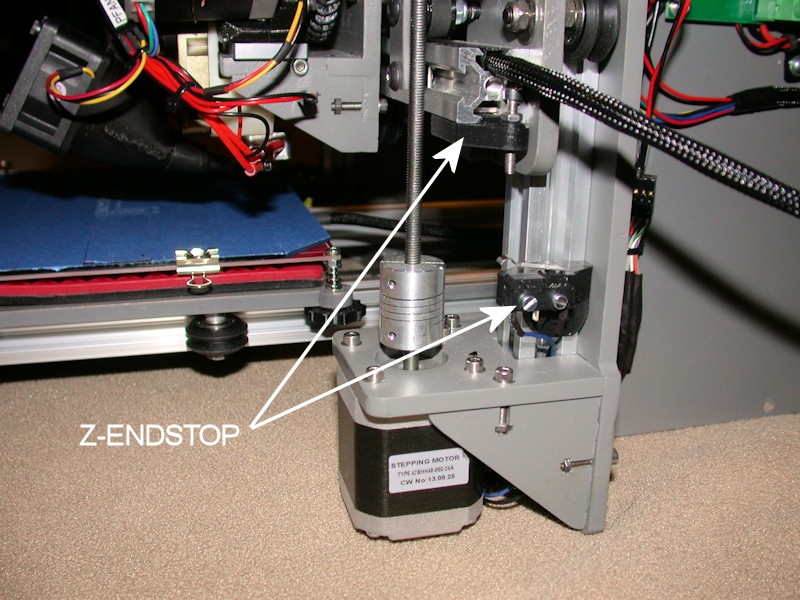

With a hefty pat on the back, Clough42 also has a replacement design for the irksome 8-inch i3v Z-endstop - http://www.thingiverse.com/thing:336665. This includes a new v-rail bracket for mounting the endstop switch on the right-side vertical rail, and a screw-adjustment bracket that mounts to the lower X-axis rail. Very cool and very functional. He also has printable brackets for the X/Y switches, but I've left mine wood for now.

One of the attempts at the extruder motor cooling shroud completed just enough that I could use it on the X-motor. It was either use it there or throw it away. The full length print would interfere with the delrin wheel(s) on the X-motor plate. I think this one stopped extruding at about the 85% point.

FOLLOWUP COMMENT: I have the motor type that runs hot. The temperature of the X-motor may not be an issue on all MakerFarm kits.

Finally, I swapped things around so that "home" is now in the forward-left corner of the print bed. This makes it easier to clean off the nozzle just before a print starts, and the print bed orientation is now the same as it is in the slicer and in Pronterface. There's firmware magic that could have done this, but for now I just moved the locations of the X and Y endstops and reversed the X/Y motor plugs on the RAMPS board. The revised Y-endstop uses the same post sticking down from the heat bed - the switch was relocated to just in front of the Y-motor. The X-endstop got moved to the left side of the printer. IIRC, both switches had to be moved to the other side of the mounting brackets. I've set up CURA to include endcode that brings the bed forward and moves the X carriage to the far right at the end of a print.

SPARE PRINTED PARTS

Only now do I think I've learned enough about printing and managing print quality to consider printing spare parts for the extruder. I've been on borrowed time with the extruder base that had started to split (note the large washer and nut that isn't supposed to on the extruder mounting bolt in the extruder picture).

FIRMWARE

I'm still running the firmware as supplied my MakerFarm. I haven't even enabled making EEPROM changes from the LCD, so I have to manually set the extruder feed rate all the time. This has actually been intentional for my situation. I've done a number of AVR-based microcontroller projects before, and I've seen a lot of forum-code and open-source stuff that really didn't have a lot of quality to it, especially in the Arduino world. I'm not saying that's true of the Marlin/RAMPS stuff - I certainly hope it's not the case. But by not even downloading the source code, I haven't been tempted to start "tweaking" it under the assumption that I thought I could do better.Last edited by printbus; 05-03-2015 at 07:34 AM. Reason: migrated to offsite image storage due to 3DPrintBoard issues

-

08-10-2014, 08:13 PM #5

Does your bed heat indicator LCD work? I noticed the wiring seemed different than that shown on the reprap wiki photos. Great looking build.

-

08-10-2014, 08:28 PM #6

Thanks for the build comment!

I assume we're talking about the LED on the heat bed? Yes, it works. I didn't think to look at the reprap wiki on how to wire it up. I assumed the two parallel pad sets were for resistors - Without crunching the math, I figured maybe there was a power dissipation issue with using just one small surface mount resistor to provide the current limiting, and the intent was to put two resistors in parallel. I now see the wiki says to put two LEDs there in opposing polarities so that you know one of the two will light up. I just powered up the bed and when the LED didn't come on the first time, I unsoldered it and flipped it around. As long as the LED and resistor are both in series, it doesn't matter which one is "first".

When I reversed the LED, I also changed it so that the legs of the LED bend up at the edge of the heat bed. That way the LED sticks up above the heat bed and is visible from the front of the printer. All that said, there isn't much point to the LED. I hear the heat bed relay clicking on and off, and it's obvious soon enough whether the bed is warming up. As mentioned in the build post, I just added the LED since the heat bed had provisions for it.

EDIT: Before someone points this out, yes, the LED body is shaped so you can tell the + (anode) and - (cathode) leads apart. For some reason (too late at night perhaps?), I ended up soldering the LED on backwards even though I knew which way things had to go. Having probably wired up hundreds of LEDs before, it was embarrassing to see the LED not work right off the bat. Also, if the LED doesn't come on since it is reversed, one could also just swap the wires for the heat bed at the heat bed relay or RAMPS board. Polarity doesn't matter to the heat bed.Last edited by printbus; 08-11-2014 at 12:21 AM.

-

08-22-2014, 03:30 PM #7

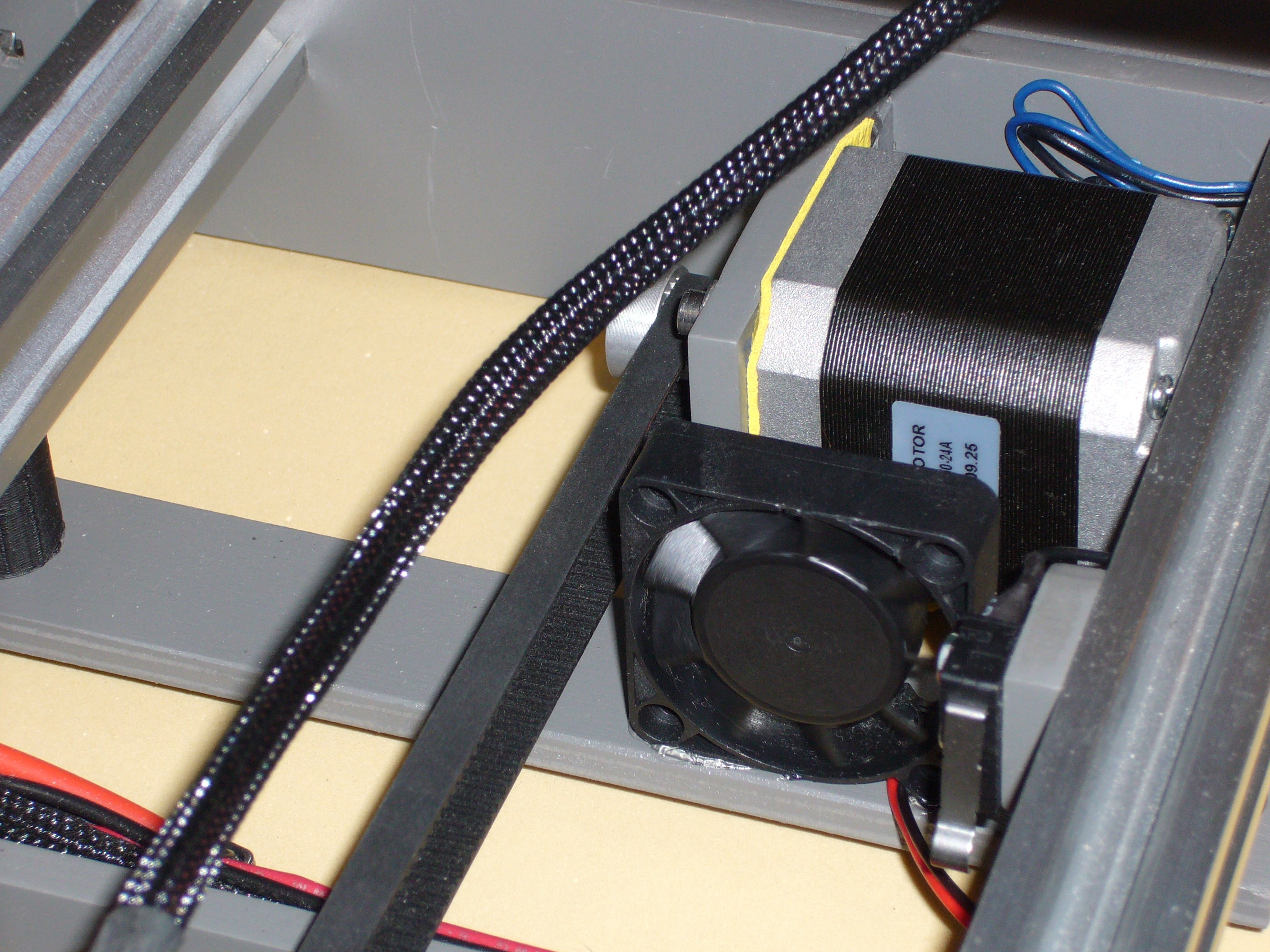

Y-MOTOR COOLING FAN

On the i3v, the Y-motor is pretty boxed in. I found it easy to add a small fan to provide some airflow to cool it down. A strip of 1/4 x 1 inch hobby plywood was attached to the bottom of the Y-bed v-rails using M5x30 button-head bolts, M5 nut plates, and 5.5mm ID x 20mm spacers derived from http://www.thingiverse.com/thing:5314. A 40mm fan was then hot-glued to the plywood. A printed design could do the whole thing and have mounting holes for the fan, but this was quicker. Using 20mm spacers, the top of the fan will be flush with the top of the Y-bed v-rails, so clearance is OK. I'm using one of the 40mm fans from MakerFarm. It doesn't take much airflow to make a big difference in the motor temperature.

You wouldn't want to bring the fan forward much more than I show it or you'd need to watch for conflict with the belt bracket on the bottom of the Y-bed as the bed slides rearward. The picture shows my relocated position for the Y endstop switch; that isn't the normal location.

FOLLOWUP COMMENT: I have the motor type that runs hot. Cooling of the Y-motor and other stepper motors may not be required on all kits.Last edited by printbus; 05-03-2015 at 10:32 AM. Reason: migrated to offsite image storage due to 3DPrintBoard issues

-

08-13-2014, 10:53 AM #8Student

- Join Date

- Aug 2014

- Posts

- 25

is there in cura settings for the 10" i3v that i can jut load in?

-

08-13-2014, 12:33 PM #9

No, but I wouldn't let that scare you away from trying Cura. IIRC, there's only four areas where settings are made. File | Machine Settings is where you'd set the size of your print area, type of G-code (set it to RepRap), etc. The Basic tab is where parameters are adjusted for almost every print - temperatures, print speed, etc. The Advanced tab has more settings that you'll likely only adjust once-in-awhile, such as first layer details. Settings under Expert | Expert Config allow you to tailor the support structure, raft, brim, etc. for when those options are enabled on the Basic tab.

Other than Machine Settings, the only thing I remember really feeling the need to initially tweak was the retraction speed and distance under Advanced. Mine is set to 10mm/sec speed and 1.0mm distance. As clough42 has educated us, the MakerFarm extruder motor works better with a slower retraction speed, and we don't have a Bowden setup so the default of 4.5mm retraction distance is excessive for us.

Ultimaker has an on-line manual for Cura that walks through what you need to do for your "first print" with it. That'd be a good place to start. The manual is focused on those with an Ultimaker printer, but they do have info on how to use Cura with non-Ultimaker printers.

-

09-12-2014, 01:49 PM #10

EXTRUDER REBUILD AND NEW PRINT COOLER (Part 2 of 2)

PRINT COOLER

FOLLOWUP COMMENT: According to an end-of-life notice from DigiKey, the manufacturer has transitioned the specific fan suggested here to obsolete status. I believe Mouser has already dropped it from their catalogue. DigiKey still had stock the last time I checked. It may not be available for future readers of the thread. Unfortunately, the fan was used because of its very unique mounting provisions, and I am not aware of a suitable substitute.

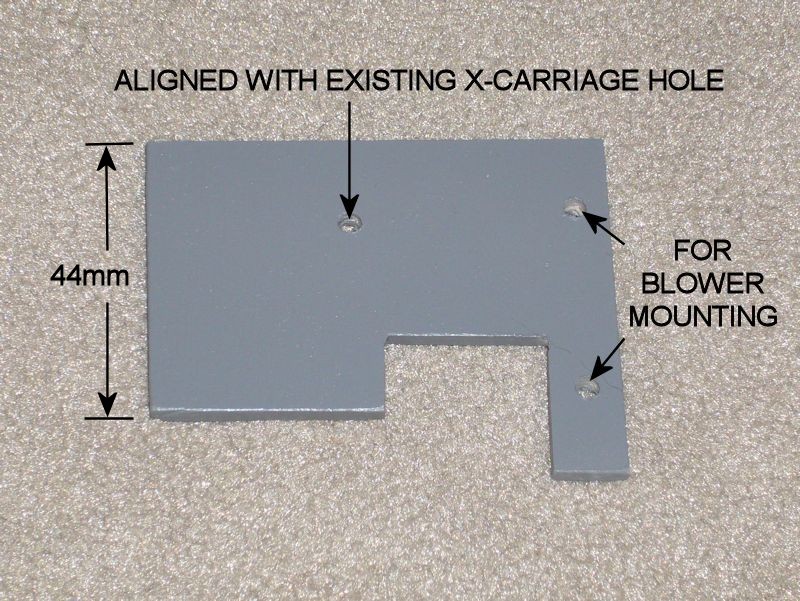

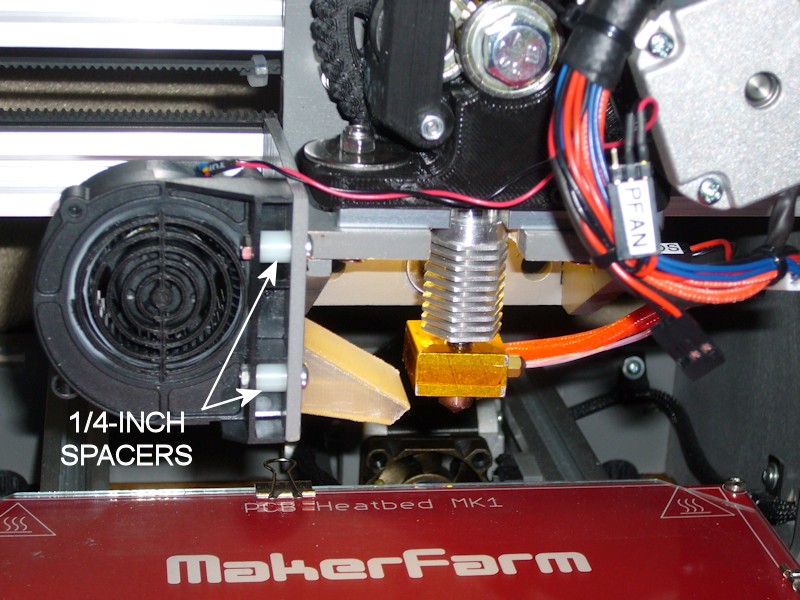

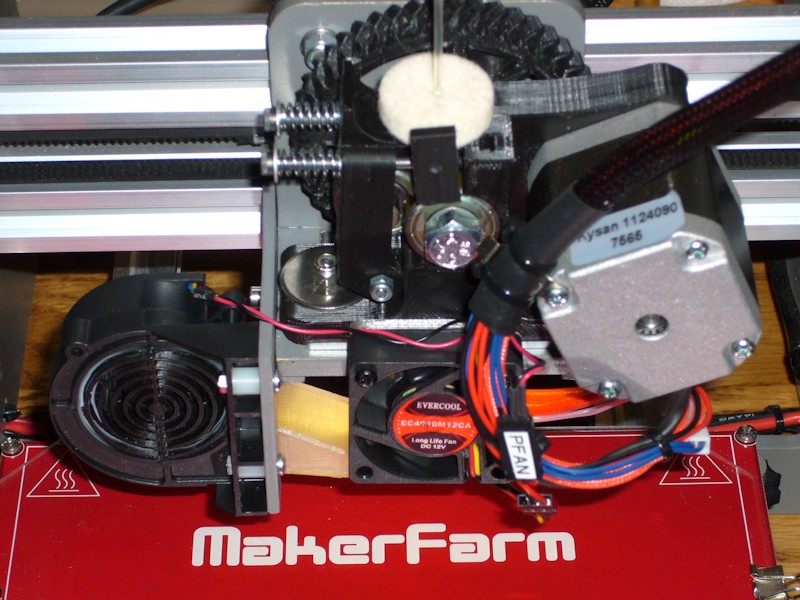

Since putting a focusing shroud on an axial fan creates backpressure that usually reduces fan airflow, this time I wanted to use a radial blower for the print cooler. After considering several concepts, I opted to go with a Delta BFB0512VHD-SP01 blower mounted onto the left side of the X-carriage. I added a grille to the blower intake by aborting a print of http://www.thingiverse.com/thing:401935 as the ring part was done, trimming off the part of the rings that didn't fit into the opening of the blower.

I fastened the blower to a 64-mm by 54-mm piece of 1/8-inch hobby plywood that attaches to the existing X-carriage, replacing the original bolt on the left side of the carriage with a longer one. This specific blower is unique in that it has mounting provisions on the face with the blower opening, providing a straight shot from the blower to the print. One advantage of having the blower on the separate bracket is that the connectorized print cooler assembly can be easily added to or removed from the printer.

The blower is located forward enough so that the blower outlet clears the angled sidewall of the X-carriage, and located just high enough to provide binder clip clearance above the print bed glass. A simple duct inserted into the outlet of the blower helps keep airflow off the hot end. The adapted version of the final duct I'm using is http://www.thingiverse.com/thing:461014. The duct is just press fit to provide some adjustment to the airflow angle, and to allow the duct to be swapped out without a lot of fuss.

Especially combined with a straight-shot duct (no right angles or rotational vortex to worry about), this is a very effective blower. Cooling is very adequate with the fan only running in the 10% range. At that speed, the audible whine from the low frequency Marlin uses on the fan PWM overpowered the low blower noise. This was resolved by a minor firmware change to have Marlin use the higher frequency fan PWM (see MINOR FIRMWARE PERSONALIZATION). The airflow is also focused and linear. At 100% blower speed, air from the blower can be felt several feet from the printer.

Note that the blower used is a 4-wire type. The red and black wires are wired to RAMPS D9. The other two wires aren't used. I cut them off and insulated the cut ends with small heatshrink tubing.

FOLLOWUP COMMENT: On large, straightforward prints where cooling won't be an issue, I've been running the blower at 10%. On more complex prints, I'll let Cura set the print speed between 10% and 25%. On really complex things, I'm finding it best to not have Cura control the fan speed and I'll do it manually through Repetier-Host. That way I can increase the speed to as much as 100% if I sense the need to for a bit, or I can back it down if I see the blower dropping the hot end temperature too much. When cooling is enabled in the slicing, Cura apparently sets the fan speed on every layer, so trying to manually override the temperature with Repetier-Host only works for the balance of that layer before the fan speed is set again in the gcode.Last edited by printbus; 04-22-2016 at 07:37 AM. Reason: fan is obsolete

Reply With Quote

Reply With Quote

Ender 3 Neo - Jam Problem

05-08-2024, 03:06 PM in Tips, Tricks and Tech Help