Results 2,911 to 2,920 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

08-22-2016, 08:28 PM #2911Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

If we assume the thermocouple channel is reading back the correct value, and that the heater control electronics is functioning properly, then there must be a reason the heater is not transferring enough heat into the hot end to achieve the target temperature. Either something is sucking the heat out, or something is keeping you from pushing enough in. 1.) Have you changed the thermal wrapper or added fans, or made some mechanical alteration that would increase the thermal mass or thermal conduction out of the hot end? 2.) Have you done anything that might reduce the heat conduction path from the heater cartridge into the hot end? Like adding a sleeve, or some layer of non-conductive crud between the heater and the block. Or maybe bad electrical connections to the heater element or possibly a bad heater element: Measuring the two heater cartridges on my QiDi they both appear to be about 14.1 ohms across the unplugged cartridge at room temperature.

-

08-22-2016, 08:41 PM #2912Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

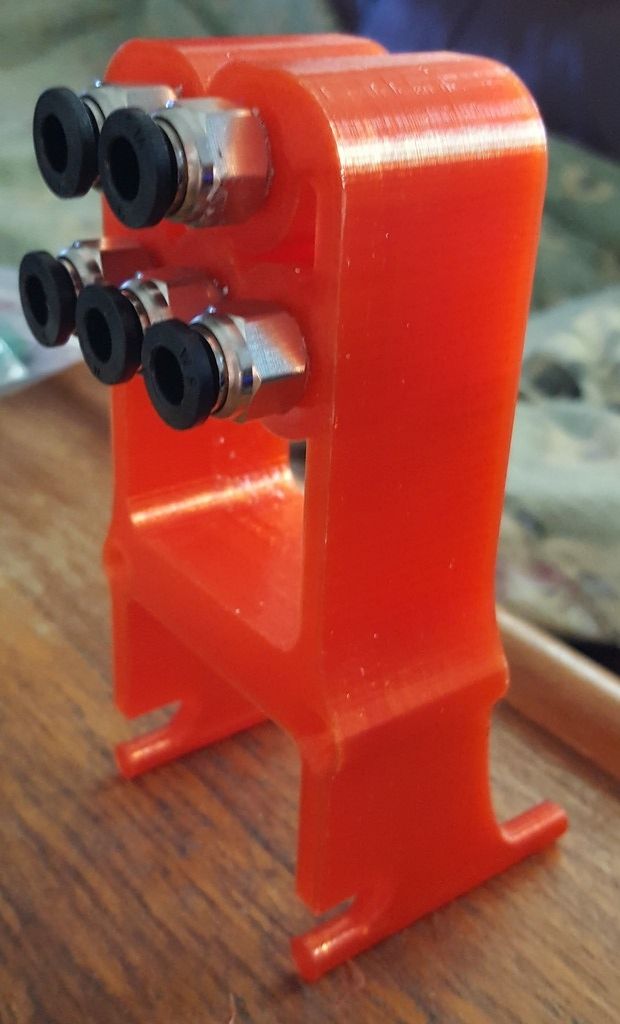

That looks right purdy W. I like it. Just keep the bends in the tubing really slow and loose on the way to the dry box. Set up one PTFE tube run like you want it to be, and try it out. Thread it up and move the filament thru the entire path by hand. Note the friction added by the PTFE tube vs that added when also pulling the filament off the roll. Check how the required force changes depending upon the filament's position on the reel that the filament is feeding from (middle or sides relative to the exit point from the dry box).

-

08-23-2016, 12:45 PM #2913

-

08-23-2016, 03:47 PM #2914Technician

- Join Date

- Mar 2016

- Posts

- 52

jfkansas, sent you a PM regarding your excellent Z-axis rework. Not sure if you get PM notifications. About to pull the trigger on another set of cheap Chinese LMF8LUU bearings... but would rather not.

-

08-23-2016, 03:55 PM #2915

Hey there, saw it earlier today just didn't have time to respond yet.

-

08-23-2016, 06:45 PM #2916Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 902

-

08-23-2016, 09:07 PM #2917

Auto bed levelling

Anyone have success with auto bed levelling on the Qidi Tech 1? I'd be interested to know exactly what you've done.

-

08-23-2016, 09:43 PM #2918

I trained my fingers to auto level. Takes about a minute to do and many many less parts.

Gotta think, to TRULY auto level you would need servos/steppers on all three adjustment points. A sensor to probe each adjustment point would be needed along with circuitry and programming to make it all happen. Is it worth it? I don't think it is. It is why almost no machines do it.

-

08-24-2016, 02:40 AM #2919Student

- Join Date

- Mar 2016

- Posts

- 29

how many of you print duel colour objects.

in my case its almost never and i am thinking of doing away with the second stepper and extruder set up.

Just wanting to know what your thoughts on this are

-

08-24-2016, 05:48 AM #2920Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 902

I haven't done a dual extrusion yet but am wanting to. My main setup is PLA on the left where the fan is and ABS on the right. With the nozzles well leveled to each other I can do prints in either pretty easily with little change. I have also pulled the ABS and ran a second PLA color on the right when cooling isn't such a big deal. So, aside from ABS the right extruder becomes the backup one.

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help