Results 2,601 to 2,610 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

07-30-2016, 11:02 AM #2601Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 902

The one question I am going to have is that they have a FFF Profile for S3D but it is for the Replicator/FlashForge. Don't know if I should actually use it or just work the settings for the QIDI profile. Maybe someone who knows more than me can look at them and see what the real difference is.

-

07-30-2016, 11:22 AM #2602Engineer-in-Training

- Join Date

- Feb 2016

- Posts

- 360

Hey wirly...got your package Monday, should be no problems.

Have had a crazy busy week, but should be able to get on this sun or mon.

-

07-30-2016, 11:46 AM #2603Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 902

-

07-30-2016, 01:42 PM #2604Engineer

- Join Date

- Aug 2014

- Posts

- 627

70%? WOW, that means your layer height * 0.7 is your first layer height and that is rough going. You would need a dead flat, and trammed, bed or no dice.

-

07-30-2016, 02:17 PM #2605Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 902

-

07-30-2016, 04:01 PM #2606Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 902

Anyone have a particular cable chain they like the design of?

-

07-30-2016, 04:42 PM #2607Engineer

- Join Date

- Aug 2014

- Posts

- 627

Irregularities are fine as long as they do not go outside of your first layer height. My I3's bed has a max difference of 0.2mm from its highest point to its dead 0mm point so I try and keep it at 0.28mm (uses a 0.35mm nozzle) for a first layer height.

This is the one thing S3D does 100% wrong because it should never be based on a percentage but on a set value and why it hasn't ever been changed I don't understand it. If I print at 0.1mm height I have to go figure out what a 0.28mm first layer height's percentage would be (0.32mm for a Qidi's 0.4mm nozzle) and if I change my layer height to something else I have to go do it all over again when the other slicers did this right so I don't have to keep effing with it every single time I just want to make a print with a different layer height. You *MUST* do this to insure that your first layer height does not go over your nozzle size * 0.8.

btw, doing it via a percentage can lead to some weird values for the first layer height if you look at the gcode.

-

07-31-2016, 07:52 AM #2608Student

- Join Date

- May 2016

- Posts

- 31

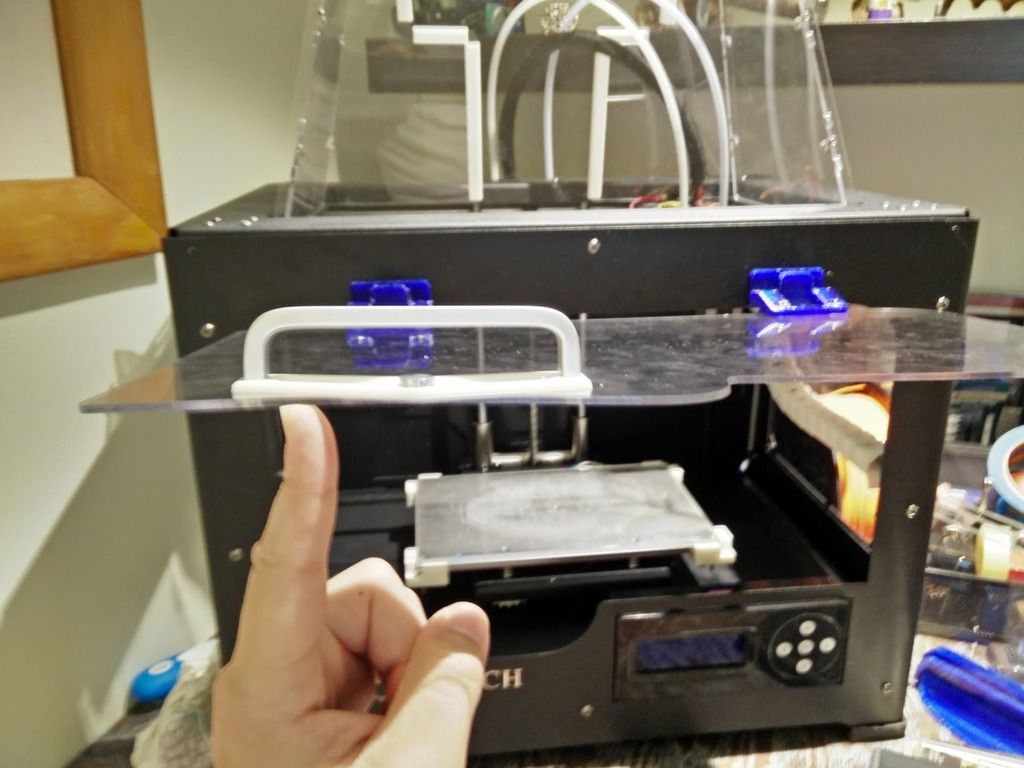

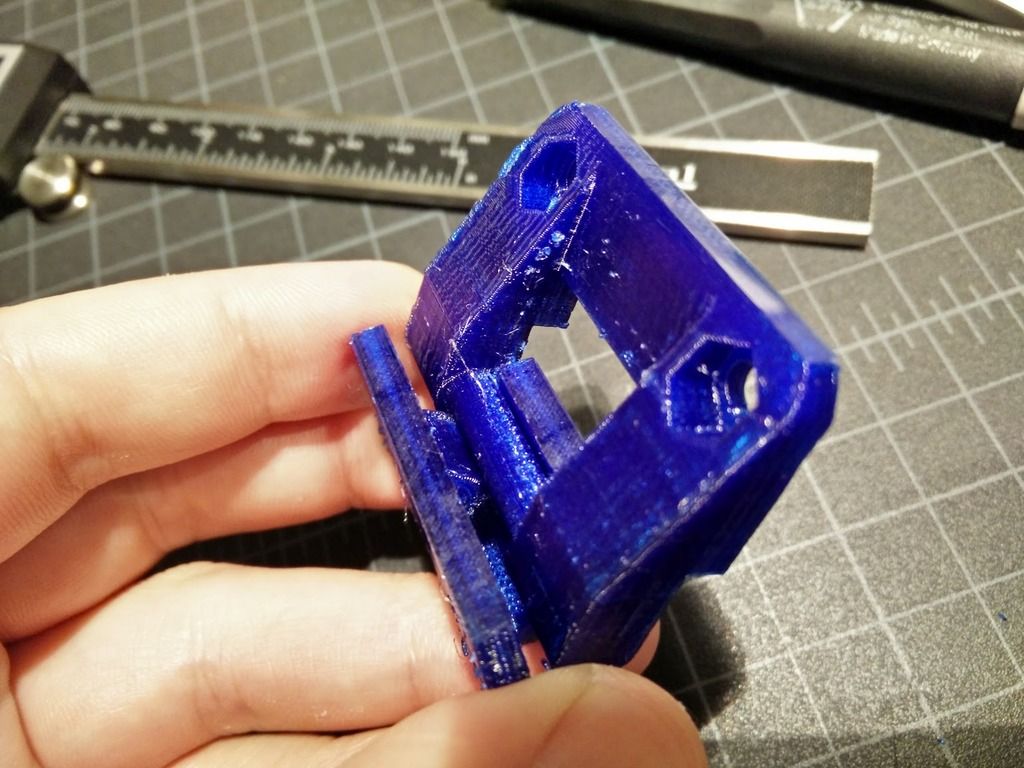

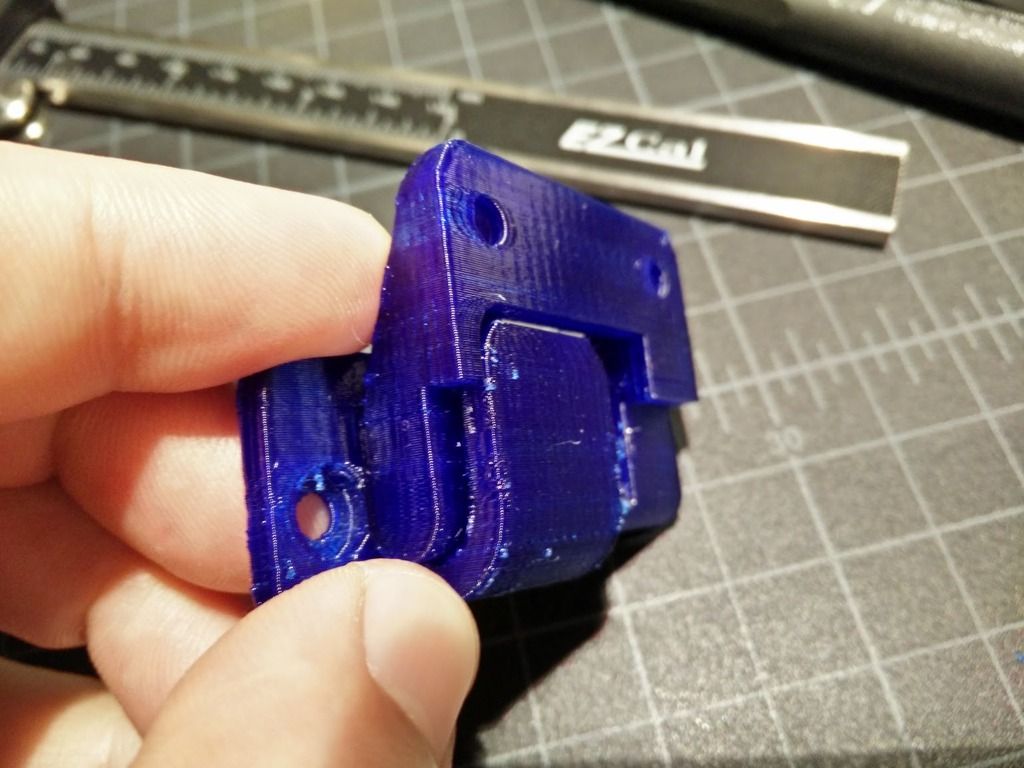

Coming back to this - I made a new open hinge version that only lets go of the door 30 degrees from vertical. It also includes the slide to lock open feature, and won't pop off the hinge in that position.

http://www.thingiverse.com/thing:1697406

I chose 30 degrees from vertical so that you can one-hand open the door through the whole part of the motion that wants to knock the door off the hinge. At 30 degrees, it needs your help to de-hinge.

-

07-31-2016, 08:18 AM #2609Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 902

-

07-31-2016, 08:33 AM #2610Student

- Join Date

- May 2016

- Posts

- 31

Hey wirlybird, I made my own and I can upload the files later today. They happen to fit my borosilicate plates from China just right (friction fit). There isn't much overhang onto the build plate so they may not tolerate plates of slightly smaller dimension.

Last edited by suds; 07-31-2016 at 02:23 PM. Reason: careless phone reply, so I said "Hay Dave" by mistake

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help