Results 2,571 to 2,580 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

07-28-2016, 11:27 AM #2571Engineer

- Join Date

- Aug 2014

- Posts

- 627

Let us know as I am already against SF due to a lot of limitations I found in it just glancing around the firmware then being confirmed by the authors. What ticks me off about the authors of SF is they tell me I don't need something so they will never implement it YET every other firmware out there does the things already. They are just not nice people and very closed minded in my opinion. Shame too.

-

07-28-2016, 08:51 PM #2572Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 902

I think the glass I have for the bed is not flat. I can measure at the two front adjustment points and get it good but equally in between those two points it seems to be higher. Suggestions on a good place to get it from?

-

07-28-2016, 09:05 PM #2573Technician

- Join Date

- Mar 2016

- Posts

- 52

Your X Y gantry is sagging in the middle from the weight of the extruders. Thats why it appears as though your glass is not flat

-

07-28-2016, 09:48 PM #2574Engineer

- Join Date

- Aug 2014

- Posts

- 627

Exactly.

All printers sag in the middle if they are using 8mm smooth rods (an 8mm smooth rod held at both ends that is 350/370mm will sag on its own) over about 300mm long.

Can you believe that originally these things used 6mm? Anything less than 10mm will sag horribly and to be honest 12mm is what everything should be using or doing what a few printers are doing and going to V-Rail aluminum extrusions so they don't sag. They even go to Bowdens but I would prefer a direct drive on 20x40, or even 20x60 if dual direct drives, instead (Bowden they use on 20x20).

-

07-29-2016, 09:02 AM #2575Technician

- Join Date

- Mar 2016

- Posts

- 52

Hey all,

I am receiving a second Qidi Tech controller in the mail to see if it improves my situation. I also plan on figuring out a way to upgrade the controller to official Sailfish. Will keep you posted...

-

07-29-2016, 10:39 AM #2576Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 902

What do you guys recommend/use for first layer settings for PLA in S3D?

I am getting a little bit of incomplete lay down of the material - gaps etc on the first layer. I thought bed level but I am not sure.

I increased the extrusion multiplier from 90 to 95 and it helped a lot but it also made the subsequent final layers much "rougher" when compared to the same piece printed at 90 which prints really great. My thinking is I need to address only the first layer and not all layers. Does this make sense?

-

07-29-2016, 10:44 AM #2577Technician

- Join Date

- Mar 2016

- Posts

- 52

I print with 100% extrusion multiplier and 100% first layer height for all my prints. Most important part is to dial in your initial z-gap or z-offset for the first layer. This is all dependent on the thickness of your business card or piece of paper you used to level your bed. Plug that value in as a negative value for z-offset. In my case z-offset is set to -0.25mm (the thickness of the business card I used to level my bed).

-

07-29-2016, 10:45 AM #2578Student

- Join Date

- May 2016

- Posts

- 31

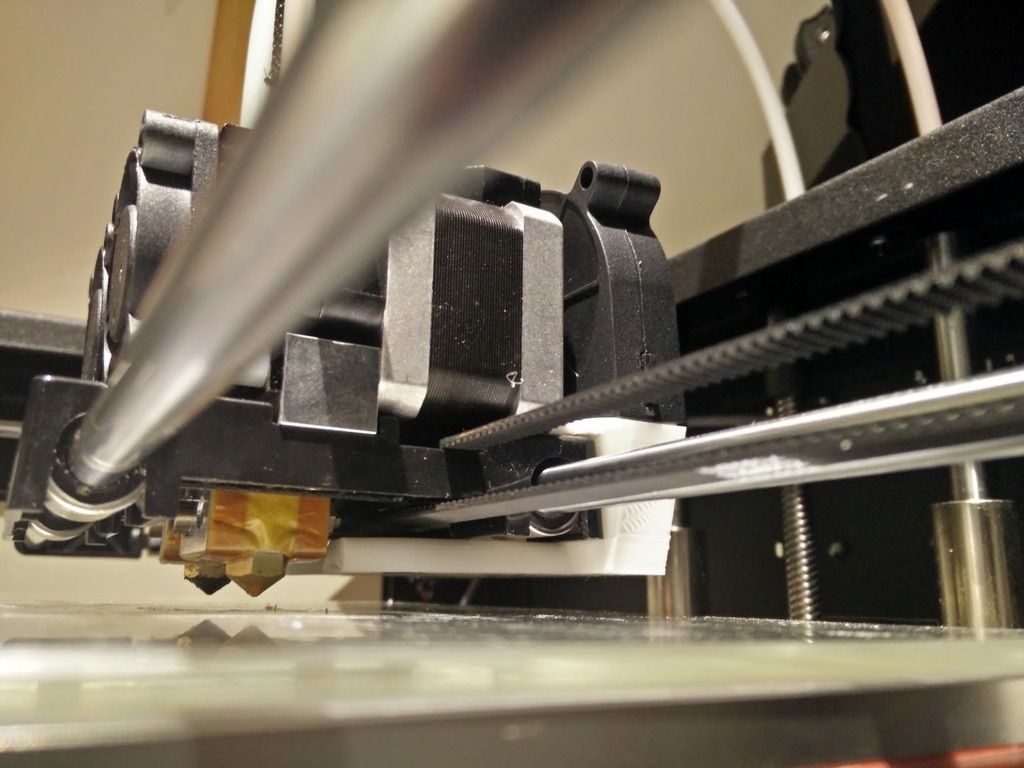

Buds, if anyone is interested in a rear mounted dual blower, I uploaded one on thingiverse: http://www.thingiverse.com/thing:1695189 It needs a 2nd stock blower, or one of the same dimensions.

It's working great so far. I used it on a 4 hour print.

Happy printing.

-

07-29-2016, 11:24 AM #2579Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 902

When I increased the multiplier to 95 the first layer was good but when it printed the final layer it was very rough to touch and visually. With the multiplier at 90 the final layer is perfect but the first layer suffers this is for PLA, I do use 100 for ABS.

I am trying first layer width and height adjustments to see what happens. I will also try the Z offset.

-

07-29-2016, 11:25 AM #2580Student

- Join Date

- May 2016

- Posts

- 31

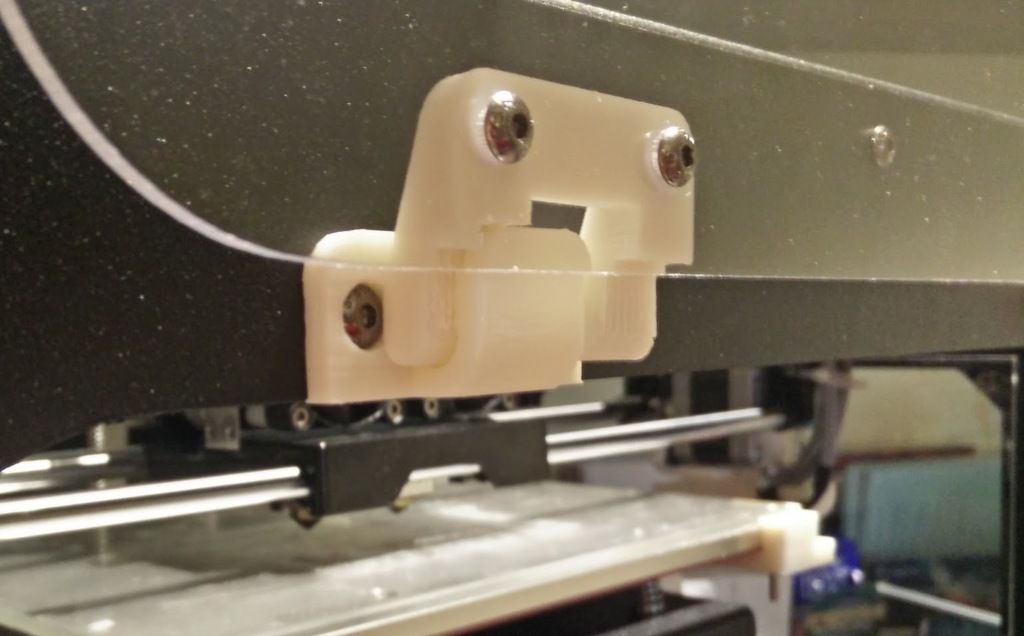

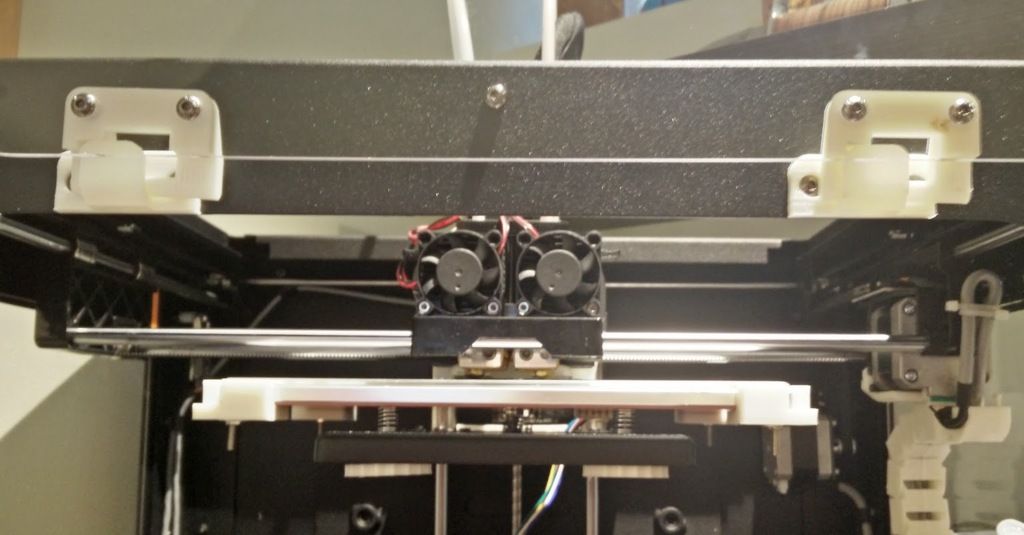

Also, if you notch out a piece of these hinges (http://www.thingiverse.com/thing:1597284 not my design), you can simply slide the door to the right (or left, per your notches) in order to keep the door held up. I find this is way easier than the add-on door holders. A chisel makes this a quick mod

... or I suppose you could edit the print file.

... or I suppose you could edit the print file.

Here are some photos to demonstrate. Sorry about the quality:

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help