Results 1 to 10 of 95

Thread: 12" I3V Build

Hybrid View

-

03-02-2016, 02:45 PM #1Technician

- Join Date

- Nov 2015

- Posts

- 73

I thought about printing something to lock the bottom nut. I like the thumb wheel on the bottom better though as then the hotend and stuff around it will never be in the way trying to fiddle a hex key into the head of the screw and I don't need any tools, besides a piece of paper or my feeler gauge. Place the hotend over the part to be leveled, one hand on the feeler, other on the thumb wheel tweak till it just slides under. Got one that printed ok last night and got it installed. Works really well.

Wanting some feedback on what I should be changing to get my PETG prints better. Thought I was doing better than I apparently am when printing the idler pulleys. Am I under extruding, hotend temp too low or have I maybe leveled my bed with too much space to the nozzle?

https://goo.gl/photos/tBLiXoRCtCeVfUFN7

https://goo.gl/photos/6VU628gR7xVeJW4V7

-

03-02-2016, 04:24 PM #2

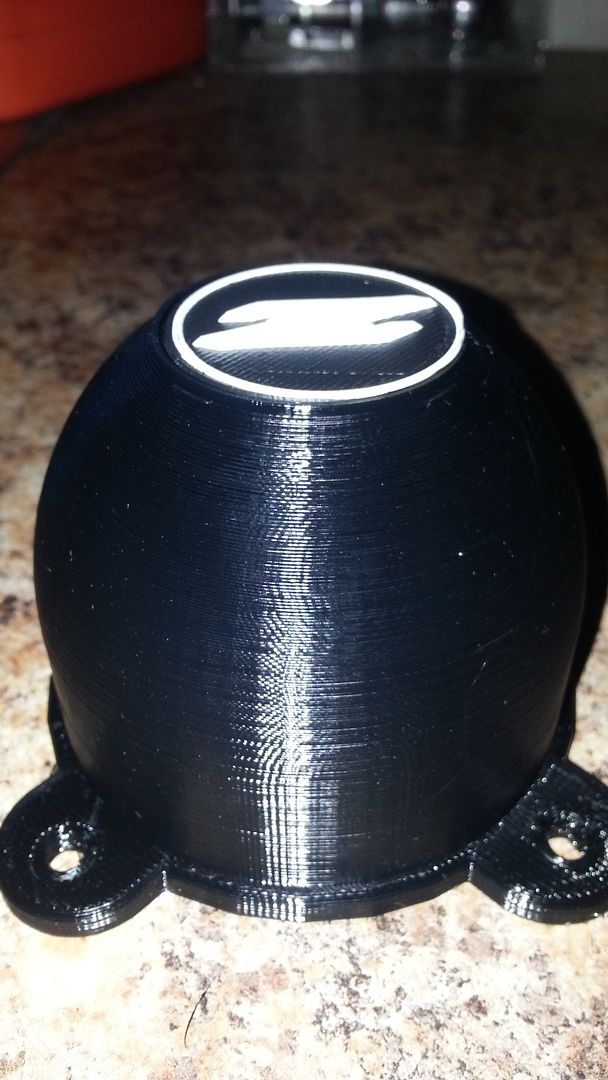

This was just printed PushPlastic Black PETG. .3 layer 260c extruder E3D Itty Bitty Flexv2. 60c bed 40% infill 3 solid outer and inner shells 4 solid top and bottom layers no brim no support.

Reply With Quote

Reply With Quote

Holes and pockmarks in print walls

06-04-2024, 09:14 AM in General 3D Printing Discussion