Results 1 to 10 of 354

Thread: 370mm X 250mm X 300mm

Threaded View

-

08-08-2021, 01:27 PM #24

OK you blew my mind with the delta IDEX. Is that even possible? I mean with separate carriages? Can't be. Can it? I will make this commitment right here and now buddy. IF I get my 3 color mixing printer figured out. Despite how rigid it is I absolutely hate the way it looks. So if I find the success in my Geeetech 3 in 1 mixing hotend, I will use that and just transfer over that hotend and get 3 tiny dual drive orbiter extruders to make it as close to a DD 3 color mixing delta as humanly possible. And I will do it with 3 smart filament sensors. Either a custom built frame or a minimum size of the Tevo little monster. God I wish I could find funding or a way to pay for my life so I could just play here.

I need help with getting the printer to behave as I want. I think this is all in the slicer. When the tool change happens the extruder in use raises a bit and shoots over to home and then the extruder to be used comes out to the exact place where the last extruder was. Once it is here it will wait for a sec in this spot on the print until the nozzle temp settles which deforms the print a little, and then it will go over to the wipe tower before coming back to start printing. I need to make some changes to this order. And if I could figure out how to just extrude a few mm of filament before each extruder comes out of park and runs over the wiper than no I don't need a prime tower.

I am still using Autodesk 123d design. Please don't shame me.

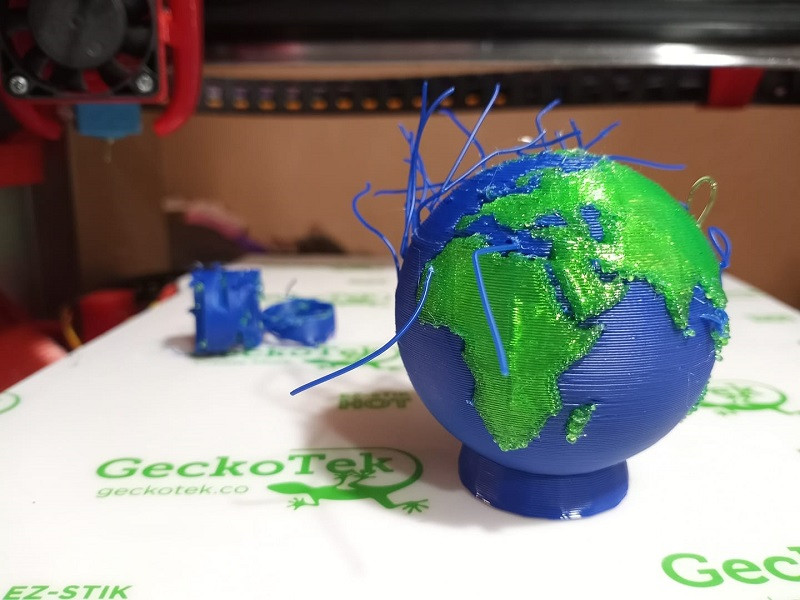

This globe is printed with PETG. Both nozzles are 0.6mm and I sliced it at 0.4mm layer height. The prime tower that Cura builds is but one line wall thickness and the PETG needs to print slowly and I think the speed is a bit high on the prime tower printing as it fell over and let go from the bed. Otherwise I would have one sweet globe right now..

Reply With Quote

Reply With Quote

New to 3d printing looking for...

05-20-2024, 12:56 AM in Tips, Tricks and Tech Help