Results 71 to 80 of 173

Thread: My First CoreXY

-

04-09-2021, 11:06 PM #71

And this, I mean, this right here is pure beauty. The best the day has to offer. Oh I can't wait to get it..

50 watt heater cartridge and Slice engineering has done away with their high temp thermistors. They say that the overwhelming majority never use it and so their hotends can have better control resolution over temps with a 300c thermistor. Or something like that. So I get a 300c thermistor and only my other Mosquito has the high temp sensor that identifies as 68 in Marlin.

-

04-10-2021, 12:26 AM #72

Keeping it in perspective, You aren't using a dragon hotend on a Bondtech extruder without a groove mount adapter. And so with a Bondtech extruder you will use the Mosquito hotend for one handed nozzle changes.

-

04-10-2021, 11:17 AM #73

That sounds like an excellent way for you to break into the wonderous world of sharing files on Thingiverse. I love sharing files on Thingiverse and watching to see how many downloads each thing gets. Sometimes people even comment and leave you feedback on their experience with your design.

Last edited by AutoWiz; 04-10-2021 at 02:14 PM.

-

04-10-2021, 10:26 PM #74

Well that's great. But why are you posting that up in my build thread for my TronXY 500 Pro printer??? Why wouldn't you go start your own thread to brag on and post links to your doings?

Last edited by AutoWiz; 04-10-2021 at 10:41 PM.

-

04-10-2021, 10:44 PM #75

I never asked you to post any link or share anything you have ever done in my build thread. You need to read all that again.

Last edited by AutoWiz; 04-11-2021 at 12:34 AM.

-

04-11-2021, 10:46 AM #76

-

04-11-2021, 01:02 PM #77

you know there's real money in a machine that can print a working cat !

-

04-13-2021, 09:16 PM #78

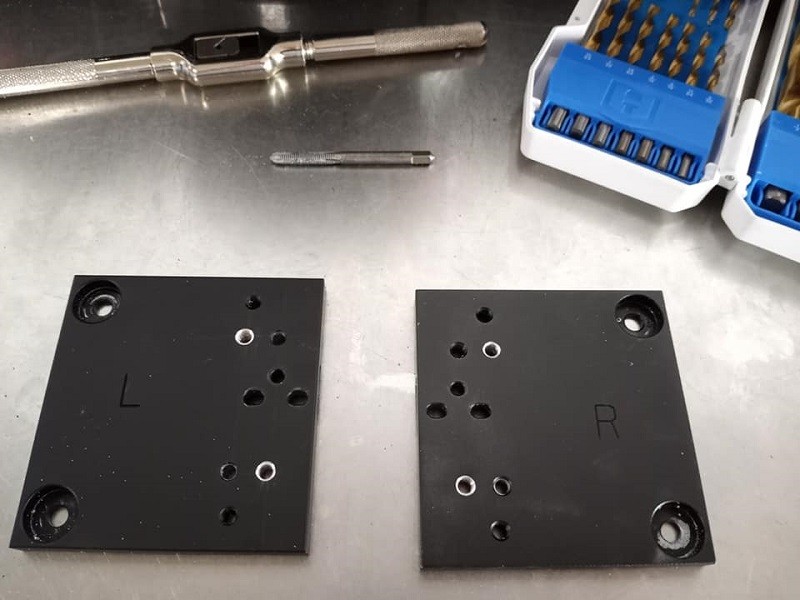

I got to make the modification to the linear guide plates for Y. Because I am flipping the belts around so they cross over in the back I need to change the orientation of the pulleys and for this to happen new holes had to be drilled and tapped. I was able to hold one plate directly over the other to line up and mark my holes. And I drilled them holes in a drill press..

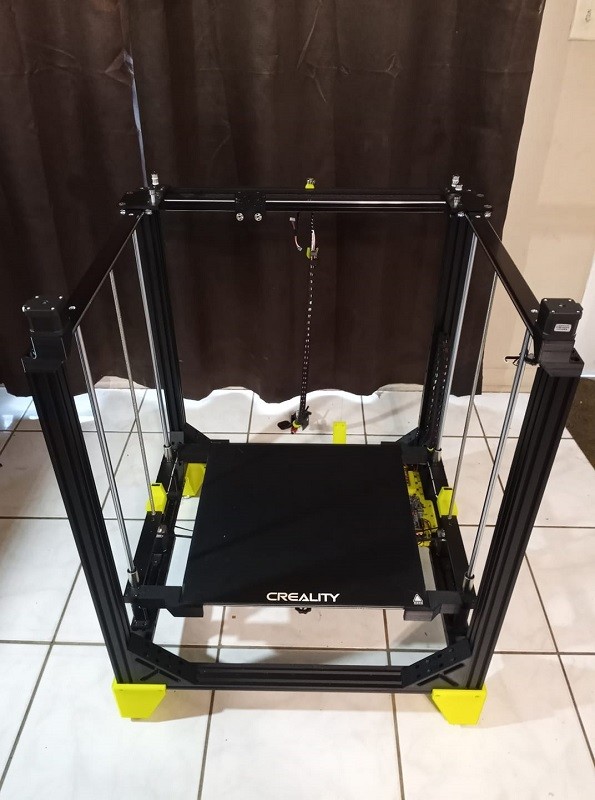

With the guides back on the rails for Y the very next thing I need to do is mount the stepper motors up front without the cross bar. So I am making this part that when perfected I will mirror and print for the other side. I might do the final part in black but for now here is a mockup of how my X and Y motors will now mount..

-

04-17-2021, 11:59 AM #79

So I am happy with the way this looks now. I think I will call this the WFO rework when I am done. The one problem now is what to do with that big screen. That tft70 is absolutely huge. And I want the printer to be no larger than its aluminum extrusion external dimensions. Just so it will fit through doors. And I don't want anything blocking the path I just opened up.

Also I found a path forward to try to correct the ongoing ringing problems I can't seem to rectify across so many different printers and reworks(all with Marlin). And I think I found that solution in Klipper. Or at least I want to try it anyways. With Klipper I can attach an accelerometer to the printer and correctly tune accelerations. Klipper calls this process 'input shaper' and it seems to me to be the best way forward for me to chase this problem. But also Klipper does not like the tft's and with it my printer will have no onboard UI which fits well with the look I am trying to achieve here. I have a small handful of pi's floating around from other projects and fun. I have a zero, a pi 3 model B+, and a pi4 4gb. I will try the best pi first. Gotta do some rewiring before I ever used the rig but This right here is the way to go. big and open in the front. It will be a pleasure to remove things from this build surface..

-

04-20-2021, 01:15 PM #80

it did occur to me the other day that rather than a complete rebuild (which I know you enjoy). You could have simply made the top cross bar easy to remolve.

Lock it in place with a simple locking handle on each side.

And that way you'd retain proper stability and also have easy walk in access.

:-)

But then I thought - that would be way too easy lol

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help