Results 1 to 10 of 174

Thread: My First CoreXY

Threaded View

-

04-09-2021, 10:50 PM #11

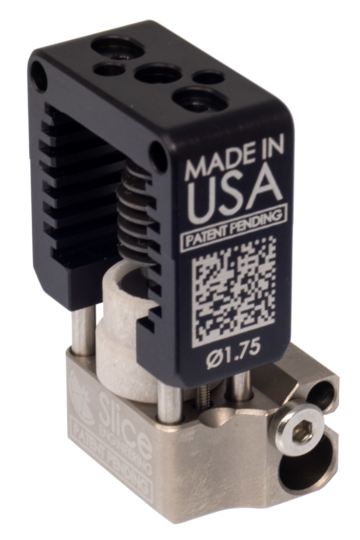

Ok so I will teach you this time. But then you need to calm down on trying to correct everybodys post. Just here in my threads OK?? So the dragon has 2 tiny little shit screws that are meant to hold a groove mount adapter or maybe be screwed directly to something but not withstanding any torsional loads. Or have you never held one in your hand and see these screws? So anyways, the Mosquito does have these screws to mount the hotend but it also mounts on these dowels so it can easily and comfortably handle torsional loads of installing and removing a nozzle. This is a proprietary Slice Engineering thing. Here is a view of the top of the mosquito hotend. The dowels are on the extruder and the dragon will not use the raised surfaces around where the screw holes are on a Bondtech extruder meant to work with a Slice Engineering hotend..

And here is a dragon with the groove mount removed..

And just to help you visualize the issue you are gonna run into doing like you suggested here is the mating surface of the LGX extruder..

Now ya sure maybe you can live with that little gap between the extruder and hotend and who knows maybe it won't become a point of jamming. But it sure as hell won't be as strong as the part that used them dowels, wouldn't you say? And even if it all did work, it would just look out of place and weird, no? to have these mis matched parts that won't even mate up to each other properly? I mean is that how you build your printers? I hope not buddy.

Reply With Quote

Reply With Quote

Printer will print perfect...

06-14-2024, 10:44 AM in Tips, Tricks and Tech Help