Results 31 to 40 of 173

Thread: My First CoreXY

-

10-23-2020, 08:07 AM #31

-

10-23-2020, 11:29 AM #32

-

10-23-2020, 01:53 PM #33

it does go up and down - technically that's moving :-)

But I guess if you start out on i3's the rest of the industry is kind of different :-)

So when you getting a delta ? totally non-moving bed.

Calibrate once - and pretty much never again :-)

It's not just that I like spending other people's money - Deltas are pretty damn cool.

And you can use one of these, you could stick one on cuboxy, but kind of wasted: https://flex3drive.com/product-categ...drive/g5-flex/

-

10-23-2020, 11:42 PM #34

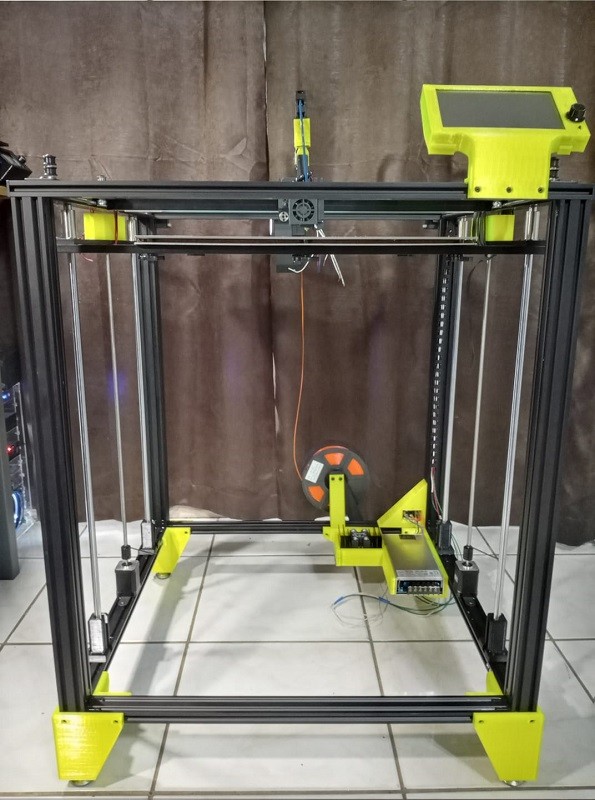

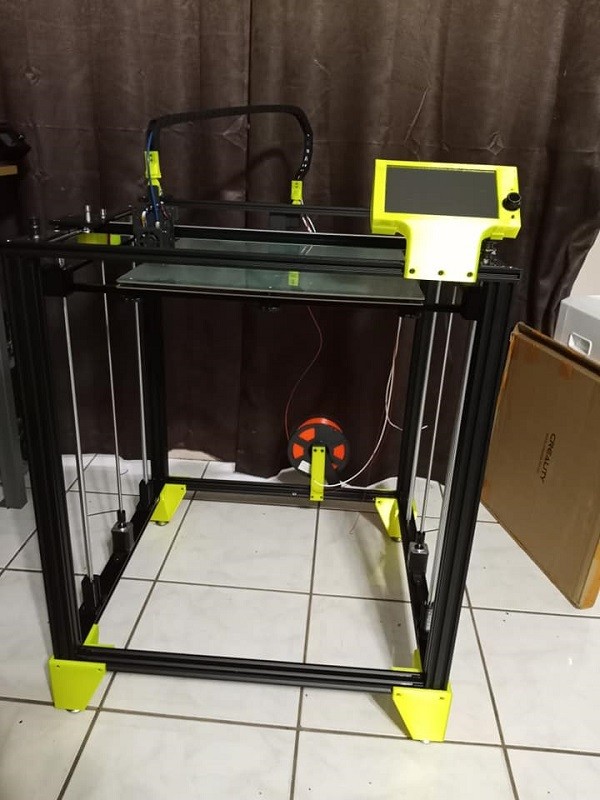

I know I always wanted a delta, too. I just need more space for my hobby. In the meantime for any other TronXY X5SA owners out there that like my printers long legs, I shared my design on Thingiverse here: https://www.thingiverse.com/thing:4632403

-

10-26-2020, 05:56 AM #35

well for a timker toy that takes up almost no deskspace: https://www.amazon.com/Monoprice-Cal...3709338&sr=8-1

price seems to have gone up in lockdown - but used ones or open boxes can be had on ebay for around $100 :-)

Hmm, looks like they might have been discontinued - even ebay prices are stupidly high.

It will print pretty well out of the box (no actual assembling required). But really requires a little tweaking for best performance.

Mine is currently back to 0.4mm nozzle aftre a brief period with a 0.25.

But back pressure is too much and the extruder needs to be moved to halfway up one of the support 'legs'.

Unfortunately while the 0.25 worked great for short items, it just jammed totally at about 40mm height.

The extruder isn't great and the friction generated with the bowden tube and it's pathway - is ridiculous.

But as a cheap introduction to the system - great little machine :-)

And lots of things you can do to it for cheap !

Mine actually takes up NO desk space at all, as it sits directly on top of the he3d k200 :-)

In idle moments I've thought about making a really tiny delta to sit on top of the mini.

But, probably not lol

-

10-28-2020, 09:57 PM #36

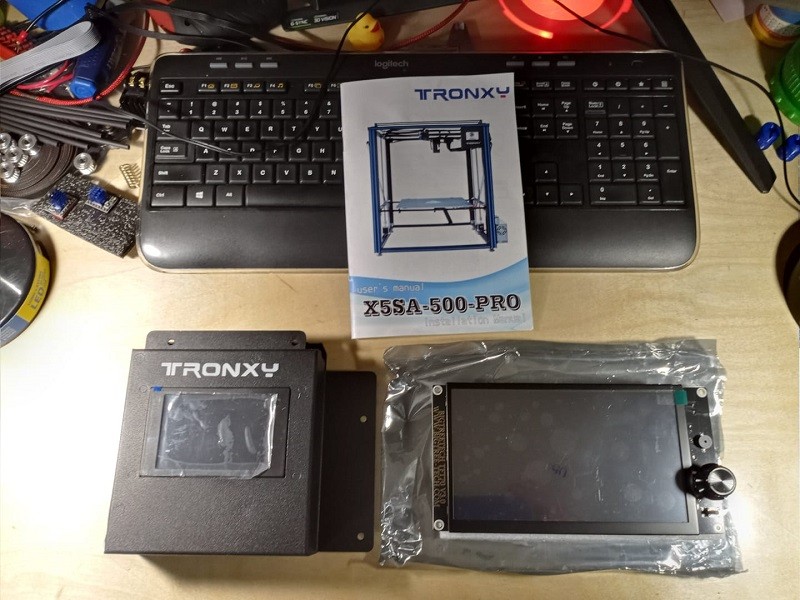

I wanted to get my hands on a Tevo Little Monster a while back. I though I would have had a blast with one of them. I can't believe a printer this big came with a 3.5" display. So here is a side by side comparison of the 2 screens. On the left is the one that came with the printer that will never get used and on the right is the BigTreeTech TFT70 V3.0..

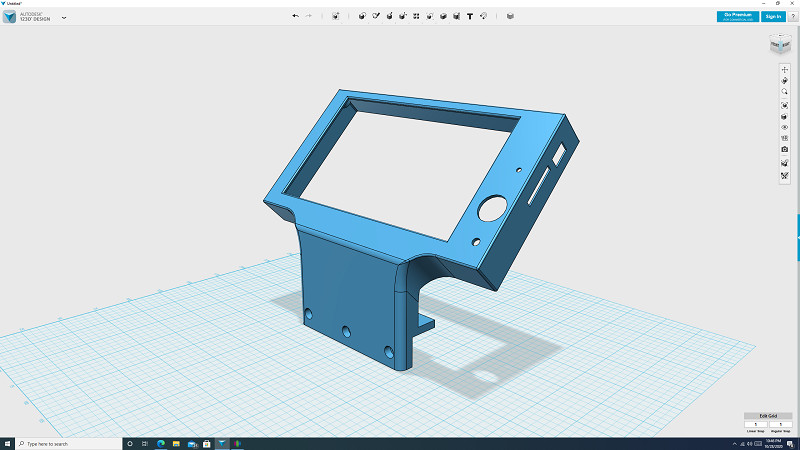

I have drawn up this mount for the 7" touchscreen that I will share on thingiverse as soon as it is done printing and I verify it fits right..

-

10-29-2020, 08:56 AM #37

lol - I love the little 3.5 screen on the sapphire.

But then I've never had a touchscreen on a 3d printer before :-)

plenty big enough for me. It's not like I'm watching youtube videos on it :-)

yeah the little monster is a decent machine. The whole suspended extruder business is fascinating. Most manufacturers use elasticised suspension cords and the extruder shakes about like it's got st vitus dance.

I've also seen one that used rigid rods and the extruder just mirrored the effector movements. Harder to do, but it would seem to make more sense.

-

11-14-2020, 06:04 PM #38

-

11-14-2020, 06:10 PM #39

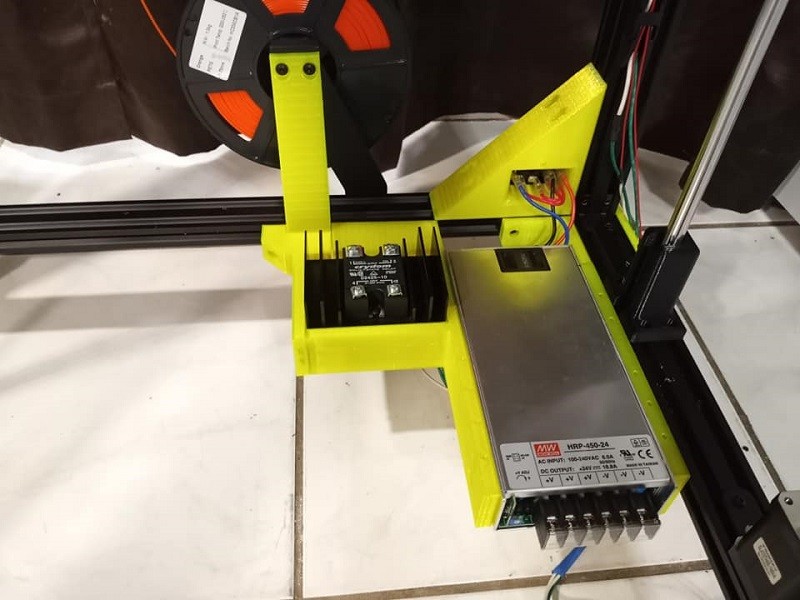

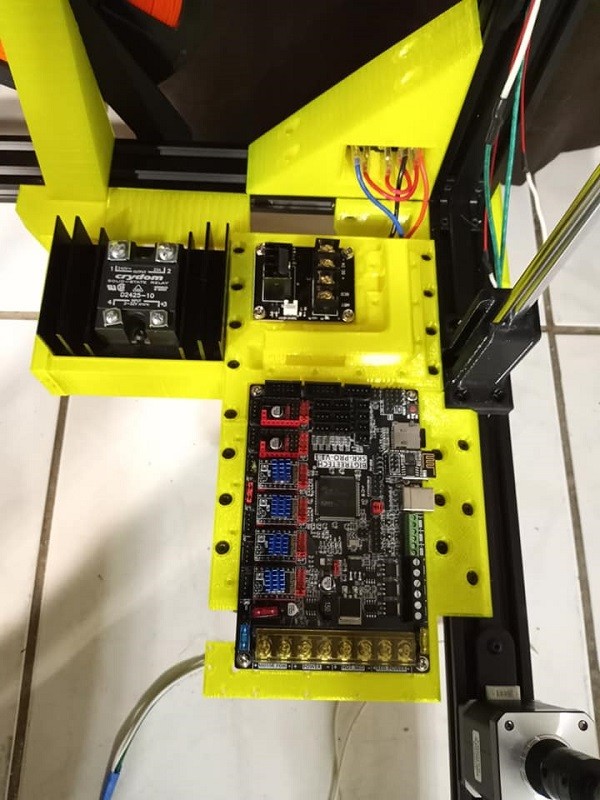

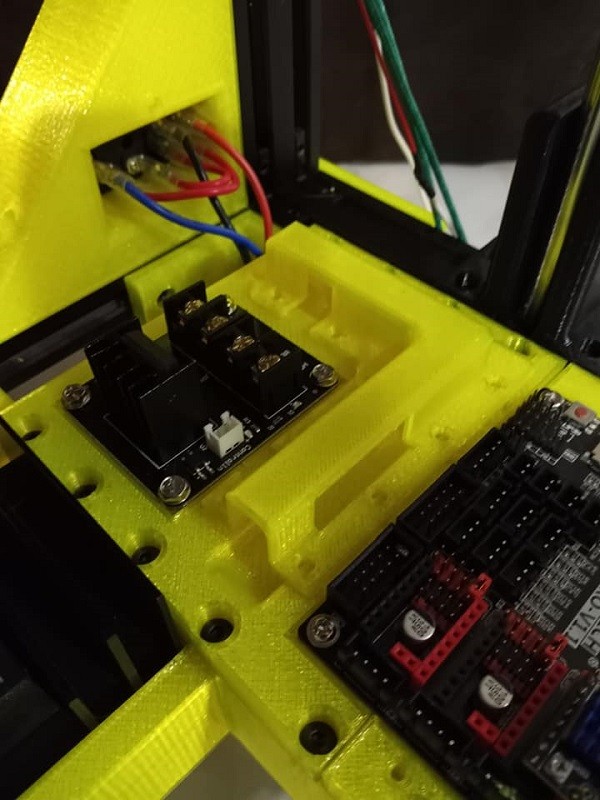

And I have been busy designing and printing mounts for the electronics. So far I have the Power supply, plug, switch, and the solid state relay and it's heatsink mounted to the frame..

I still have to print a tray to hold the mainboard and the mosfet for the extruder. I should be ready to start wiring this up soon..

-

11-19-2020, 10:51 PM #40

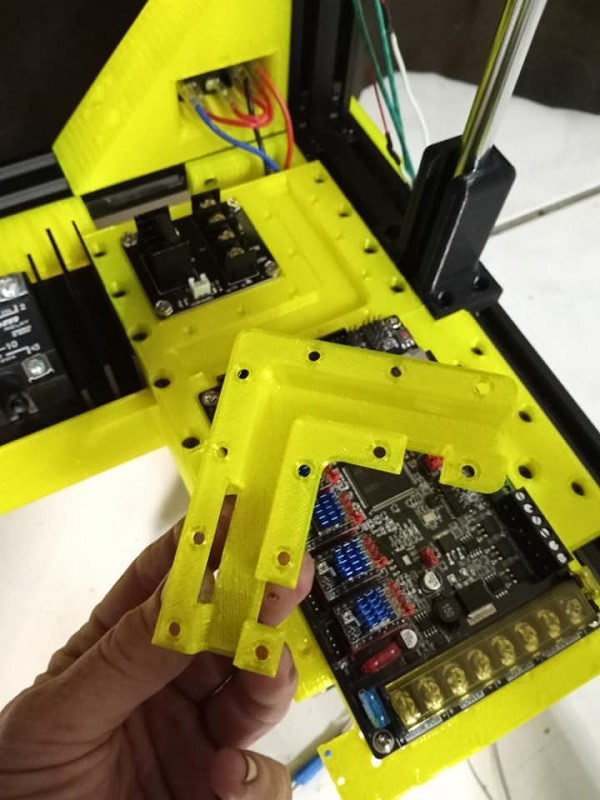

Well alright, we have finished mounting all the electronics. Everything is mounted rigid and strong. To match the printer's frame. All of the bolt holes are equally spaced at only 25mm apart which created a pretty cool look I think..

I like to run external control for all the heaters on my printers just to take the warmth of that current flow away from the mainboard. It might seem like overkill to some, but I have one printer with a mosquito hotend from Slice Engineering and it uses a 50 watt heater cartridge. This is a good place to have a mosfet with a heatsink attached and you wont get that on a mainboard. just a wider path on the board for that circuit in hopes it will dispel the heat on it's own. So this TronXY will run a SKR PRO 1.1 along with a Crydom solid state relay to send 120v to the bed heater and a smaller big tree tech external mosfet to drive the extruder's hotend. And this time I am trying for an even cleaner wiring job than I usually am good for..

I made covers to hide the wires so we should only have to look at the boards themselves..

Oh , and I dropped and shattered the 510x510mm creality ultrabase. And so I ordered another and here is my second Creality 510x510mm carbon silicone glass 400c working temp glass plate..

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help