Results 21 to 30 of 173

Thread: My First CoreXY

-

10-13-2020, 01:29 PM #21Technologist

- Join Date

- Oct 2016

- Posts

- 184

So these still have the separate Z-motors... I remember that was a PITA to keep level when Z motor current is tuned off. I designed a single Z motor mod: https://www.thingiverse.com/thing:3612257, but there are others available, I've seen one where the motor is located on the side which might be a better solution. Also for maybe more rigid bed support: https://www.thingiverse.com/thing:3630372, not sure if this works with the bigger printer, mine is X5S which is 330x330.

-

10-14-2020, 11:04 PM #22

I looked at them but my smooth rods are farther apart so those will not work. But no worries. I am going to drive this thing with a SKR PRO and 4 TMC2226 drivers. I think it would be absolutely awesome to have a printer with a glass bed that has sensorless homing for X,Y, and Z. It will make for less wires and a cleaner appearance. And it also wont matter if the bed falls to the ground every time the printer shuts off. It will level itself as it homes with the sensorless homing. I flipped the bearings upside down so the length of them sticks up and don't ya know all 4 bottom out on the top of the frame at a very good place to just use the bed screws to adjust the bed height for the first layer. So now I wish I didn't buy that BLTouch. Maybe I will send it back when it comes.

-

10-16-2020, 09:19 AM #23

so how does the sensorless homing work ?

There was a post or thread or video i watched recently (well this year) about someone with a similarly size machine who had a stepper motor at each corner. So that the auto levelling was ACTUALLY auto leveloing.

That sounds like you kind of thing :-)

I've never had a bed move when the power is off.

Admittedly all three of my vertically moving beds are held only at the back, but even without power, stepper motors don't turn all that loosely - after all the magnets are still working.

Polycarbonate is going to be your hi-temp superstrong friend :-)

And i have some sample filament of polyamide - also fairly hi-temp and supposed to be super strong - I've never been able to test the polyamide stuff: https://www.bcn3d.com/product/pa-bcn3d-filaments/

Good for up to 120c - given that most car radiators will have blown by that point - ought to be good for some parts of an engine.

And a LOT cheaper than PEEK (what isn't ? )

So despair not - you will not have to fall back on pet-g - which to be honest really isn't all that. It's soft, bendy and nowhere near as strong as pla.

Polycarbonate and polyamide - are both well within Cuboxy's usage parameters.

Yes, it has a name :-)

They might even come in colours :-)

There are probably more engineering plastics around (hell I've probably got samples of some of them).

PEEK's the top dog - stronger than aluminium - but the rest are all still pretty amazing :-)

But doesn't like uv light - so not good for outdoor usage.The polycarbonate filament can withstand temperatures ranging from -150°C to 140°C,

https://www.3dnatives.com/en/polycar...ng-110220204/#!

Can you not build a shed for the printers and set up a bunch of networked cameras ?

has to make more sense than a divorce ;-)Last edited by curious aardvark; 10-16-2020 at 09:33 AM.

-

10-16-2020, 11:20 AM #24

The sensorless homing goes with the tmc2209 or 2226 or 5160 drivers. There are 2 extra pins on these drivers one of which we have to cut if we are not using the sensorless homing. For this we should be using 32 bit boards like the SKR series so we have support for the extra pins on these drivers. Once together we tune the stepper voltage so it is strong enough to not skip but not so strong that it breaks our printers when it butts up against the frame. The driver senses the skipped steps and knows it is homed. I will show you guys my trick for sensorless homing on Z. And no shed. I rent. However, I am very much trying to get my own show on the road. My business is an LLC. And if I can get my shift together and get this off the ground then I will happily keep my printer(s) in my shop. Check out my professional logo. I paid somebody on fiverr.com for this..

-

10-19-2020, 05:38 AM #25

Ah - excellent explanation - so the stepper acts as it's own endstop sensor - clever - odd, but clever.

Presumably that means it can home in either direction.

Good logo - mind you how many americans actually know what a proper gear shift stick looks like ;-)

In case anyone doesn't know. In britain 90% of cars are manual shift and in the states 90% are automatic. I presume it's because your fuel costs about 1/3rd what ours does and automatics are nototiously bad on fuel economy.

I guess when we all go electric, that all changes.

And yeah, how do you do sensorless homing on a moving z axis ?

Particularly on a corexy - I presume you home it at the bottom of it's travel and it remembers where the start point is ?

Althogh it would probably make more sense to just have an moveable block at the top so that it's adjustable, should you change hotends or nozzles.Last edited by curious aardvark; 10-19-2020 at 05:48 AM.

-

10-20-2020, 08:53 PM #26

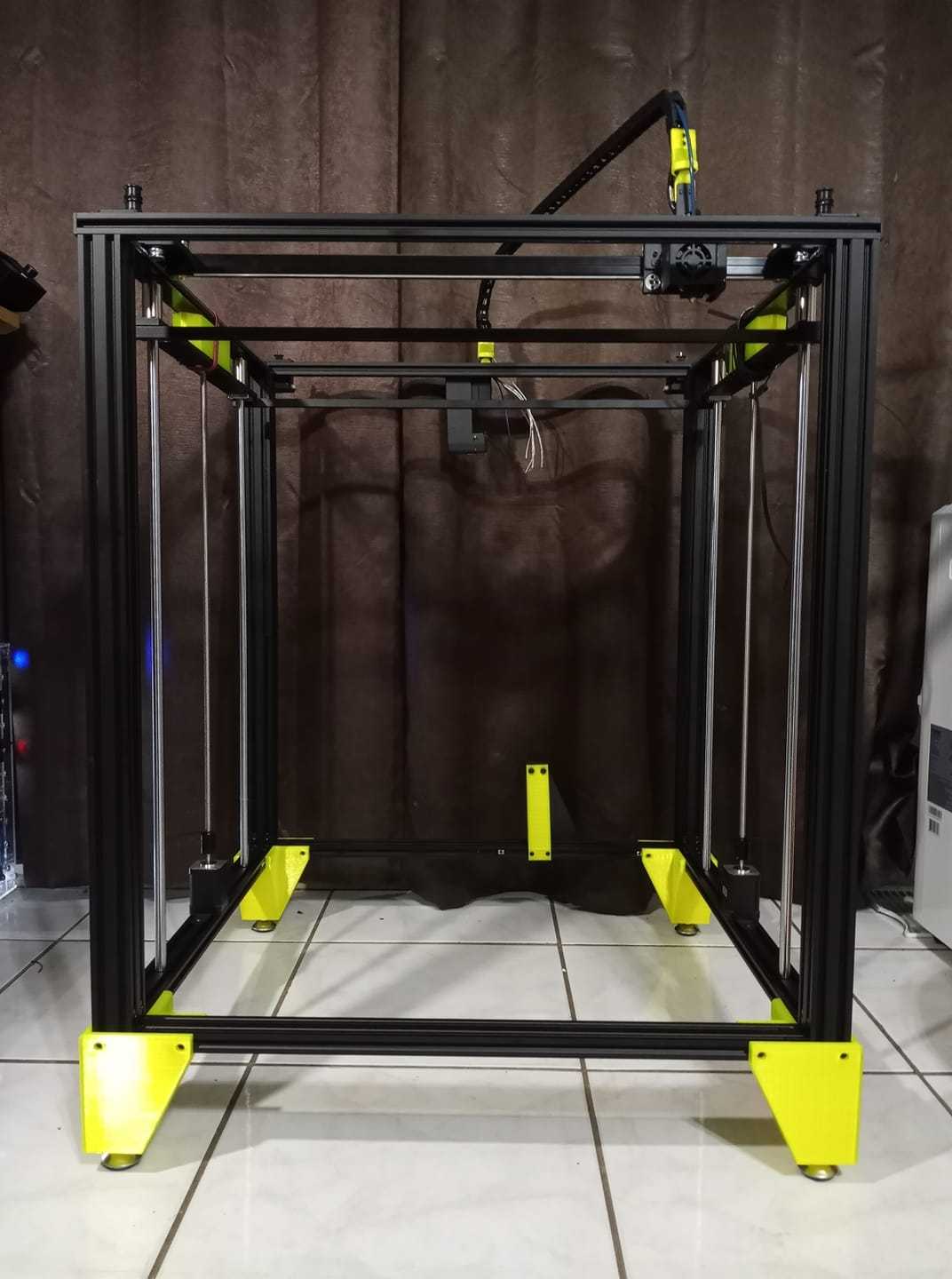

So because of the way the frame and X carriage and leadscrews are I had to make these yellow bricks so the Z carriage didn't flex and allow for extra steps from the Z steppers. When the carriage bottoms out the leadscrew needs to sop immediately. That is the yellow bricks on the carriage at the leadscrews. The yellow support at the lower rear of the frame is for the filament spool holder. It is just a plate and flexes easily so now it doesn't. There are a few spacers I made to go under the idler plates up top at the front of the machine and also to relocate the filament runout sensor so it is in line with the BondTech BMG extruder. The fewer wires inside the cable chain allowed me to put the Capricorn tubing inside the cable chain for an even cleaner look. And because the printer is so huge I am just gonna leave it on the floor so I drew up these feet that raise the printer 100mm, square the lower frame, and also moves the rubber feet out to the corners so the printer is even more stable. So far so good. The bed is off for it's mod..

-

10-21-2020, 09:22 AM #27

-

10-21-2020, 11:40 AM #28

Ya I am. But under the absolute best of conditions. Genuine Bondtech BMG extruder and real Capricorn brand tubing. I want to see how well we can get that to work. You know I am not afraid of making changes down the road. The Capricorn has a smaller ID than the rest and so the filament has less room to move about inside of the tubing and with Capricorn tubing we can usually lower our retraction settings. And even with the smaller tubing the filament pushes through it even easier than the regular PTFE. Amazing stuff. The bed doesn't move on the coreXY. just that hotend moves on X and Y. And so I want to explore just how lightweight I can get that assembly and what benefits I might actually see from it.

-

10-22-2020, 10:27 AM #29

honestly - a solid corexy doesn't notice the extra weight of even a hefty extruder like the bond-tech - pretty sure that's what mine uses.

A 40mm smooth iris box printed at 150mm/s - with the slowest being 80% of that and the majority actually running at the full 150 - pretty much answers that question.

You're going to be using proper linear rails arne't you ?

The capricorn tubing sounds interesting - might look at that for my bigger delta.

It's too small for a suspended extruder, but is currently using pretty wide bore tubing.

So what's the capricorn tubing made of ?

Some kind of self lubricating nylon ?

The bed moves up and down :-)

And have alook at this for a PEEK printer !

https://www.e-ci.com/baam

-

10-22-2020, 10:27 PM #30

Ya this is gonna go be subject to a major future rework to include a direct drive extruder and some of them HIWIN rails. I just have to recover from this round of spending. But I am unimpressed with the rails or whatever these guides are that came with the pro. They aren't ruff but they aren't exactly smooth either or as smooth as them HIWINS. I swapped the generic titan that came with the tronxy with one of the 3 new Bondtech extruders I recently put on Printalicious. And I'm not buying a hotend for it at this point. So I haven't actually spent money on the extruder aside from the tubing so far. But I will get to it. And when I get there it will likely get a BMG-M extruder with Mosquito hotend. But for now I am just gonna find a bigger nozzle. I can't believe this came with a 0.4mm nozzle. I mean the build volume is 500x500x600. Somebody has a sense of humor. Anyways the Multi Widow can build up to 400x250x330 right now and I got a 0.6mm nozzle for that so I feel like the TronXY should be even bigger like 0.8 maybe? I have to see how big of a nozzle I can get for this TronXY hotend. self lubricating is exactly what the capricorn tubing feels like. I have some off brand stuff that is blue and then I got name brand Capricorn that is a darker blue. And I am so happy to FINALLY have a printer with a bed that doesn't move about.

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help