Results 261 to 270 of 354

Thread: 370mm X 250mm X 300mm

-

09-10-2020, 11:15 AM #261

There are 2 linear rails with 2 cars (1 on each rail) for X, 2 linear rails with 4 cars (2 on each rail) for Y, and 4 rails with 4 cars (1 on each rail) for Z(2 rails on the front and 2 on the back). Best quality all genuine HIWIN ordered from motion constrained. It was the 4 Z linear rails that helped with the frame's rigidity and allowed me to remove the top cross brace from the frame. These 4 rails go a long way towards holding the frame square. It is these rails that control the Z banding and have kept it to a severe minimum. But removing the lower bearing and collars from the threaded rods will eliminate it.

-

09-10-2020, 11:24 AM #262

-

09-12-2020, 01:33 AM #263

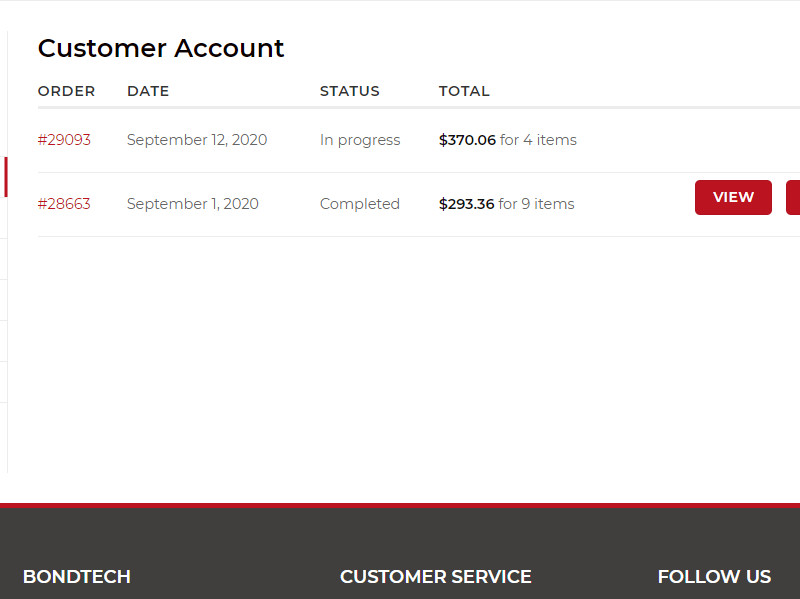

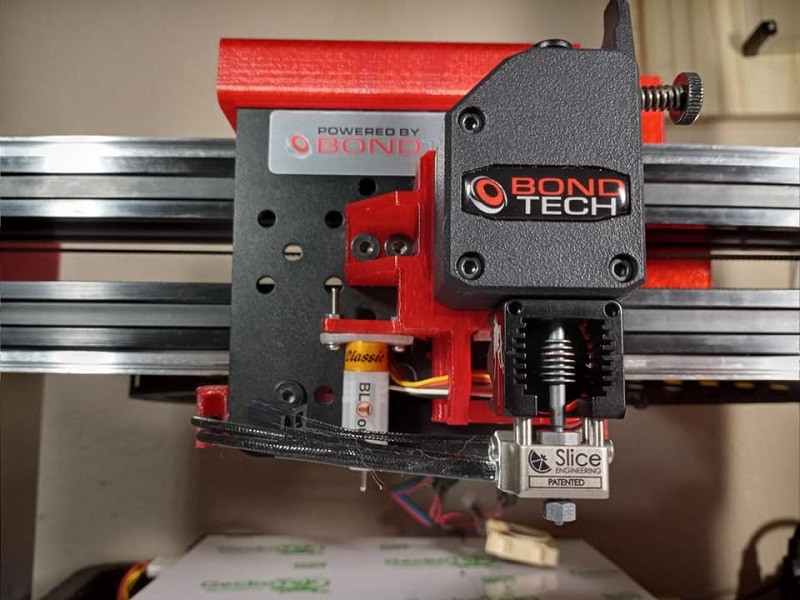

With the aftermarket metal idler arm installed with the bowden fitting screwed in the filament is held slightly off of its optimal angle and is prone to skipping or if I tighten it down enough it will just kink the filament before feeding it down. I swapped the plastic idler arm in to print those large parts with the single filament and as soon as i put the other idler arm back in I'm back to the skipping. I need an extruder i can feed a bowden tube into. I already started down the path of no expense spared with the genuine HIWIN rails and PRUSA MMU2S instead of clone parts so I have resolved this extruder problem in that same fashion and did like I said I was gonna do. Today I have ordered the Mosquito hotend from Slice engineering along with a 24v fan, 24v 50 watt heater cartridge, thermistor, vanadium 0.6mm nozzle, and BondTech BMG-M extruder. I feel all warm and fuzzy on the inside about this new extruder setup and can't wait to change a nozzle with just one hand. This new extruder setup costs more than some printers. But it is fitting and the correct part for the machine I built. Gotta treat my robot right. I ordered my parts directly from BondTech, here: https://www.bondtech.se/en/

Last edited by AutoWiz; 09-12-2020 at 01:23 PM.

-

09-20-2020, 08:35 AM #264

well if the bondtech extruder is anything like mine - I'm not overly impressed.

The fact that you can't feed any flexible filament through it at a print speed faster than 10mm/s without it somehow managing to 'escape' and wrap itself behind the gears - has not endeared it to me.

And there is absolutely nothing you can do to prevent it - short of finding someone with a metal engineering lathe and cutting a couple of new gears with enlarge back barrels that block wriggling filament.

I've even tried fitting a sleeve over the offendind part of the gears, but it just slides across the gear. Guess I could glue it in place.

Hopefully your's is better designed than mine :-)

I'm currently contemplating stripping the extruder out of my original flashforge creator (which is mothballed on top of shelving) and using that. At least i know I can make that flex proof with very little effort.

Extruders can definitely be over complicated.

-

09-20-2020, 01:48 PM #265

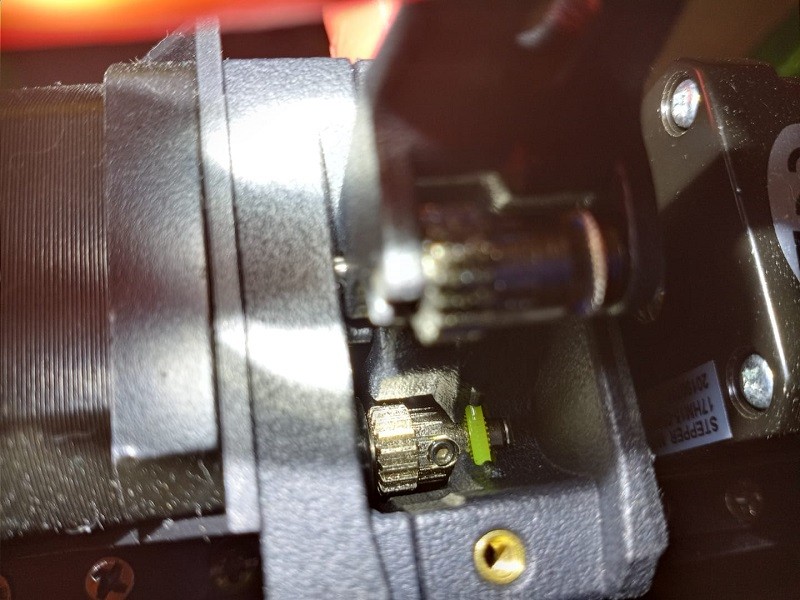

I think mine are a newer design. I currently like BondTech this much..

Did you buy genuine real BondTech or a knockoff? Inside of a real $80 BondTech BMG extruder I am pretty sure it is impossible for the filament to wrap around anything. This is looking down inside one of the 3 on my mixing printer..

The case is made so precisely against the gears on both sides. God Bless BondTech BMG. ...of course I have not printed the flexible materials with one of these extruders yet.Last edited by AutoWiz; 09-20-2020 at 02:32 PM.

-

09-20-2020, 03:05 PM #266Engineer-in-Training

- Join Date

- Jan 2016

- Posts

- 326

My SainSmart Coreception printer is supposed to have E3 Titan extruder but it may be knockoff instead of real thing. One time, flexible filament jammed inside the extruder. On Amazon's website, there are different E3 Titan extruders as well as different extruders for FlashForce Creator printers. How can I buy the real thing instead of knockoff?

-

09-20-2020, 03:36 PM #267

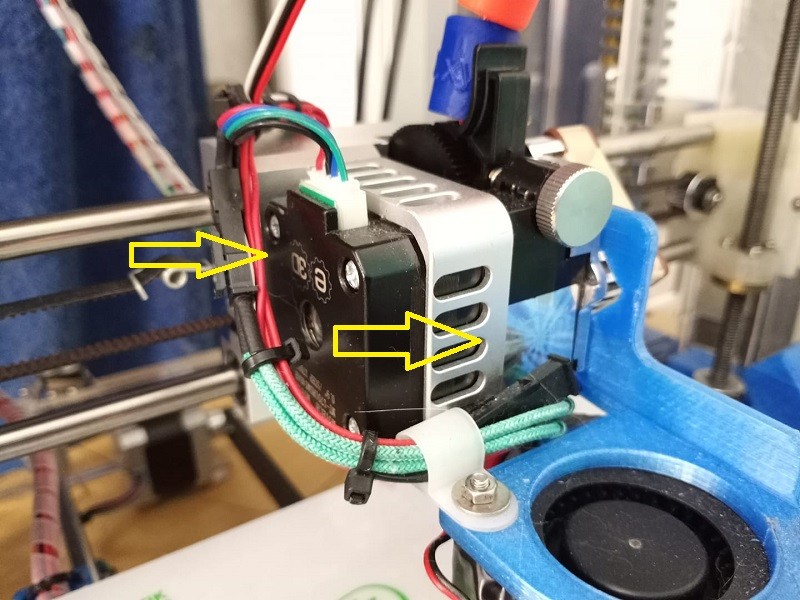

Directly from the manufacturer is not just a great way to ensure a genuine product, but it also ensures that you will have the latest version of whatever product you are ordering and that it has sat on a shelf for the least amount of time. For your Titan you would want E3D: https://e3d-online.com/ . For BMG you want BondTech: https://www.bondtech.se/en/ . For SKR and other chinese mainboards you want Biqu: https://www.biqu.equipment/ . And so on. No amazon or ebay or ali or other middle men. At best they can only add to the price. Biqu is in China so you gotta give them time to get you your stuff. And if you are going to buy yourself one of these extruders here in 2020 you really should spend your money on either the E3D Hemera OR the BondTech BMG. Both are dual drive. Sadly E3D is having troubles keeping up with demand for their Hemera. So really you should be looking at the BondTech BMG. For verification your titan extruder should have a holographic E3D sticker on it's side and the pancake stepper should have the E3D logo on it's backside. Like this..

Last edited by AutoWiz; 09-20-2020 at 07:14 PM.

-

09-23-2020, 04:48 PM #268

-

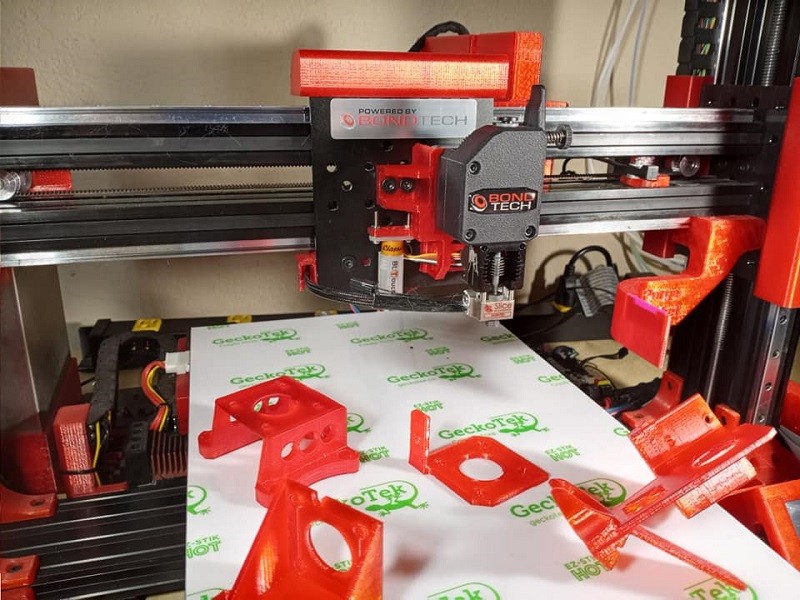

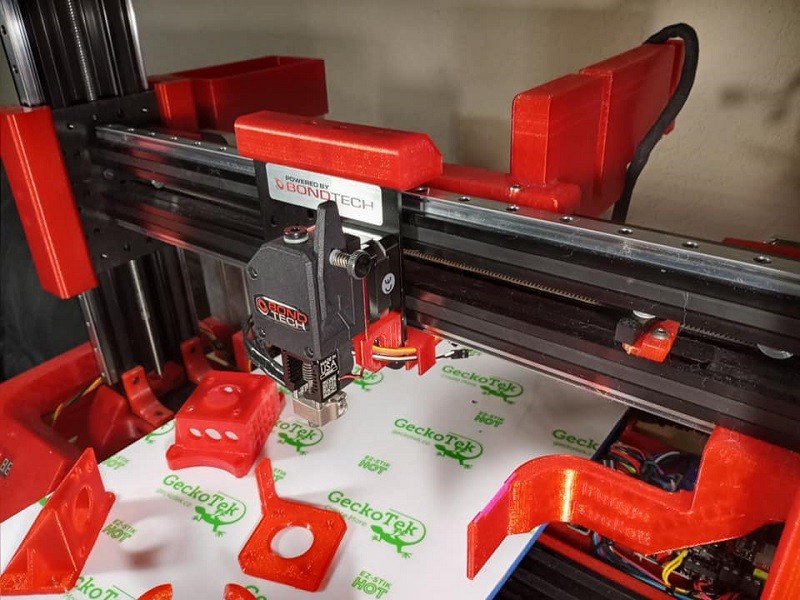

09-26-2020, 12:53 AM #269

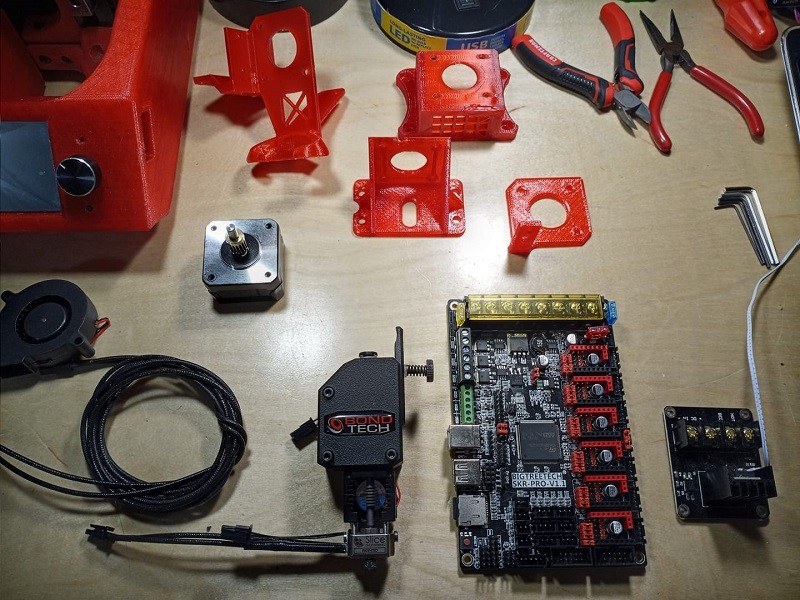

Well mission creep has officially set in. The Mosquito hotend comes with a 50watt heater cartridge and the wires that come with it are thicker than what is inside the drag chains. And I really want to add an external MOSFET for the extruder. Also The bondtech bmg-m mounts the nozzle a little further outboard from where the titan was. So I need to move the towers back a few mm on the Y so that the nozzle can reach all 400mm of the bed. And I need to swap the SKR 1.4 turbo for the SKR Pro I have. Sounds like the next rework but it shouldn't be that bad. I only have to design a new mainboard tray and extruder mount. I did try to download and print out various mounts just didn't find anything I liked. So it's time to rip this machine back down again. Electrical needs to come out so this can go in..

-

09-26-2020, 10:18 PM #270

Why is it the best extruder mounts are always the ones you make yourself? I mean you want to just hit the easy button and print something off of thingiverse and be done with it. But then you just don't get your labels displayed properly. And we do pay a price for them labels so they should be displayed..

Reply With Quote

Reply With Quote

Printing time- Is this right?

09-13-2024, 07:51 AM in General 3D Printing Discussion