Results 11 to 20 of 27

-

09-02-2020, 09:01 PM #11

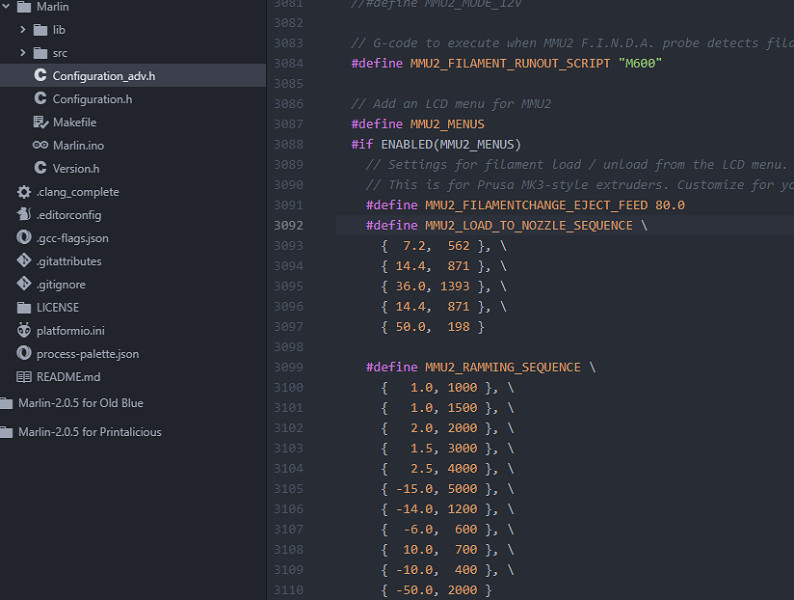

Ok now we gotta get the MMU2S up and going. I entered the menu on the mmu itself and adjusted the length for the ptfe tube from the mmu to the extruder. I was however lost on how to adjust for the distance between the driven gear of the extruder and the nozzle. I mean i know where that is, I just do not understand what the numbers are or what they adjust. And sadly i have found no real answer. The youtube video i watched on setting this up skipped over this leaving it alone because his extruder was a near identical match to the prusa mk3 or mk3s extruder. These numbers, what do the individual numbers here mean? For filament load and ramming..

-

09-02-2020, 09:10 PM #12

By following a tutorial on youtube i got as far as trying to start a print but got weird behavior out of the extruder gear and putting it in relative mode made no difference. I made this short video of what it was doing on the initial prime line at the start of a print. https://www.youtube.com/watch?v=iICQ8sENQJs&t= . That prime line is in the start gcode. I just need known good start/toolchange/end gcode for the MMU2S and to get this distance from the gear to the nozzle set right and i will be printing big stuff in color and with stunning precision.

-

09-03-2020, 12:11 AM #13Technologist

- Join Date

- Oct 2016

- Posts

- 184

I guess the number are the lengths and speeds, the loading and ramming have been split into smaller moves.

I'll have a look at Marlin after work, I wonder if the current code expects the filament sensor to be present. That's how it works on actual Prusa, but Prusa has it's own Marlin fork running and I think that shouldn't be a requirement on other printers as most don't have a filament sensor on the extruder...

The filament sensor functionality is neat, though. Now it actually detects when the filament has reached the extruder gears instead of relying on preset feed length. There was actually a smaal extruder upgrade needed, the idler and IR-sensor housing needed to be changed. There was a mention on the handbook that the special menu feed length tuning is not needed anymore due to this.

-

09-03-2020, 08:12 AM #14Technologist

- Join Date

- Oct 2016

- Posts

- 184

Ok had a look at configuration_adv.h and it seems that by default Marlin doesn have the sensor functionality enabled:

So it's something else. Have you enabled #define MMU2_MENUS?Code://#define PRUSA_MMU2_S_MODE #if ENABLED(PRUSA_MMU2_S_MODE) #define MMU2_C0_RETRY 5 // Number of retries (total time = timeout*retries) #define MMU2_CAN_LOAD_FEEDRATE 800 // (mm/min) #define MMU2_CAN_LOAD_SEQUENCE \ { 0.1, MMU2_CAN_LOAD_FEEDRATE }, \ { 60.0, MMU2_CAN_LOAD_FEEDRATE }, \ { -52.0, MMU2_CAN_LOAD_FEEDRATE } #define MMU2_CAN_LOAD_RETRACT 6.0 // (mm) Keep under the distance between Load Sequence values #define MMU2_CAN_LOAD_DEVIATION 0.8 // (mm) Acceptable deviation #define MMU2_CAN_LOAD_INCREMENT 0.2 // (mm) To reuse within MMU2 module #define MMU2_CAN_LOAD_INCREMENT_SEQUENCE \ { -MMU2_CAN_LOAD_INCREMENT, MMU2_CAN_LOAD_FEEDRATE } #endif

-

09-03-2020, 08:38 PM #15

Yes. And I can go into those menus from the lcd12864 display. I can load the filaments and unload a everything that way works. Because my titan aero is so much shorter than the prusa extruder I always end up with a blob. I entered the menu from the prusa MMU2S itself and adjusted the length of filament for all 5 filaments and saved it so it load all just fine.

-

09-04-2020, 12:07 AM #16Technologist

- Join Date

- Oct 2016

- Posts

- 184

Ok you could try changing the values in MMU2_LOAD_TO_NOZZLE_SEQUENCE, maybe lower the last value from 50 to 30 or so. The MMU2_RAMMING_SEQUENCE should be ok, not sure...

-

09-04-2020, 09:48 PM #17

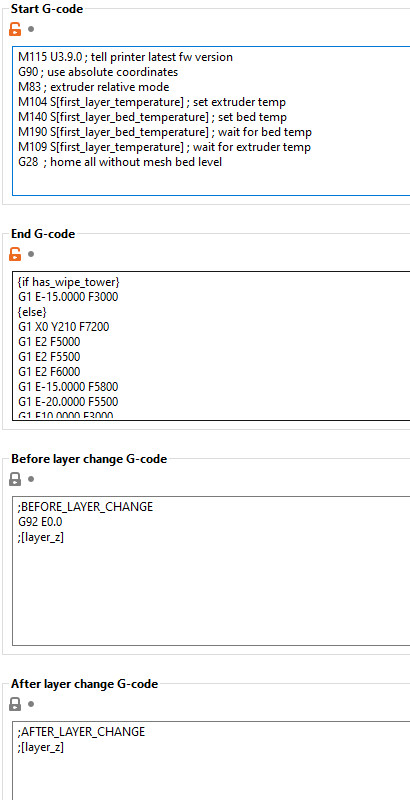

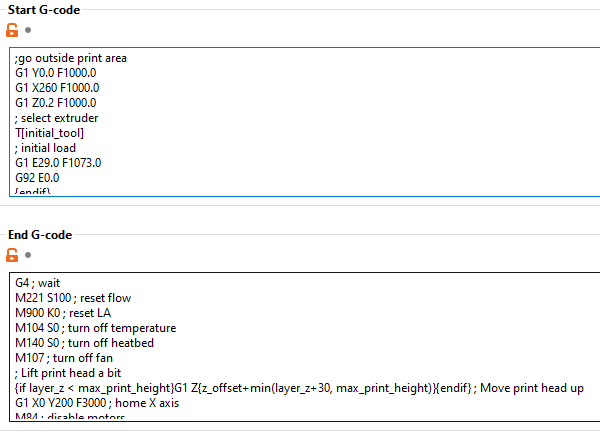

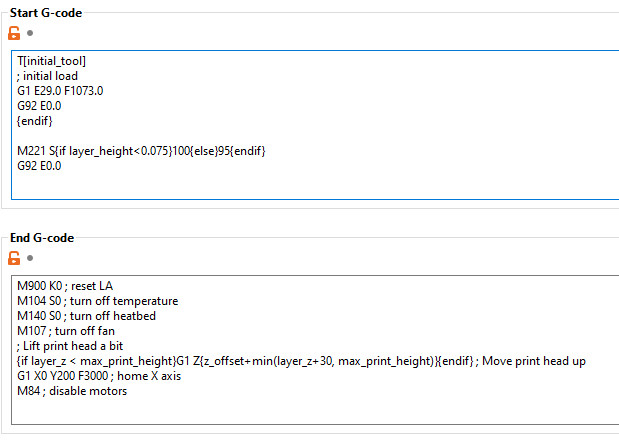

Alright I am home for the 3 day weekend. What I really need to figure out is my gcode. Buddy this is what I am so hoping you can help with. I need to know what my gcode needs to look like. I have 4 pictures of what i currently have. It is long and i do not understand it and i just need the printer to home and start the print. I need to know what minimum mandatory gcode would look like to get this up and going..

-

09-05-2020, 12:31 PM #18Technologist

- Join Date

- Oct 2016

- Posts

- 184

From Start gcode, remove M115 as it's for Prusa FW version check. Also the M221 might be Prusa specific so remove it, at least the 'official' gcode listing doesn't seem correct: https://reprap.org/wiki/G-code#M221:_Turn_on_AUX_V1.0.5. Here it seems to control extrusion %.

Other than those I guess it's all good. The M403 I suppose are in latest Marlin as MMU2S is.

-

09-05-2020, 07:58 PM #19

Thank you. I tried it and it started. I still have this problem when it starts priming the first filament and the extruder spins backwards while the x axis moves in one direction and then when it moves in the other way the extruder spins the correct way. And it goes back and forth for this prime. But when it goes to the color it is going to print with it does ok. So we are making progress. Sadly these titan extruders are absolutely killing me. I am really thinking hard about building a clone prusa mk3s extruder assembly or a Bond Tech with Mosquito. What do you think? The sound of the titan extruder skipping has become like nails on a chalkboard to me. Common as it seems to have become of late. Only with the multi material printing do I use PTFE tubing. Otherwise I am direct drive with open filament hanging above feeding straight down. very low restriction path. I always have the spring tension very light on the filament and no problem. But inside the long ptfe tubing I have to crank the spring tension down so much it deforms the filament and then it binds on its way down to the hotend. Or I loosen it and it skips.

-

09-06-2020, 08:05 AM #20

are the extruders dual gear extruders ?

I've got a bmg dual gear extruder on the sapphire pro.

I'm not convinced it's better than the mk8 on the delta.

The double gears definitely seem to grind a lot more then the mk 8 (7 ? - hang on)

this one:

That is hands down the best extruder from all 6 machines.

I think I'm up to about 8km through a 16 inch(ish) bowden tube. Never a single issue.

Whereas the bmg - only worked at all with it's bowden tube, when screwed right down to the point I can't turn it any more.

Plus grinds both sides, and it's still got a 2mm gap between the gears and the feed hole that the slightest back pressure causes flexible filament to bulge out of.

I'm going to strip it down and see if there's anythign I can do to block the gap.

Now it's direct drive, it's only got 105 mm tube that's vertical straight, so I don't have to screw it as tight.

But the gap needs blocking.

As it won't print flexibles at anything past 12mm/s.

The fixed mk8's on the klic-n-print happily knock it out at 30mnm/s.

I think sometimes the expensive, fancy extruders just don't work as well as the original simple ones.

manufacturers try and fix problems that didn't actually exist in the first place.

One other thing that might be relevant.

The bowden tube on the delta has a slightly wider bore than the one on the sapphire pro 2.

So there's very little friction on the delta and there was a lot on the original sapphire setup.

Could be an issue.Last edited by curious aardvark; 09-06-2020 at 08:10 AM.

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help