Results 1 to 10 of 132

Thread: My 3 Color Mixing Printer

Threaded View

-

08-23-2020, 08:48 PM #20

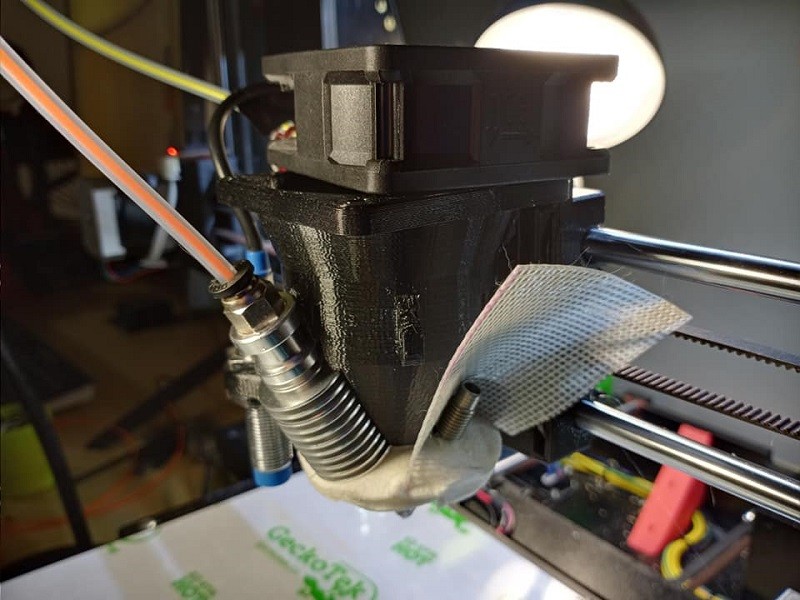

I slept on it and decided on a careful approach to clearing the jam. One by one I removed each heatsink and placed a piece of a silicone mat blocking airflow to the heatbreak allowing it to heatsoak to the 240c temp of the nozzle..

Upon teardown I realized there is no thermal paste on them threads on the cold end side. This is important. And I just happen to have the best thermal paste money can buy. Thermal Grizzly kryonaut. So a little of this needs to go on the threads of each heatbreak only on the cold end side..

Reply With Quote

Reply With Quote

New to 3d printing looking for...

05-20-2024, 12:56 AM in Tips, Tricks and Tech Help