Results 101 to 110 of 132

Thread: My 3 Color Mixing Printer

-

07-22-2020, 09:44 PM #101

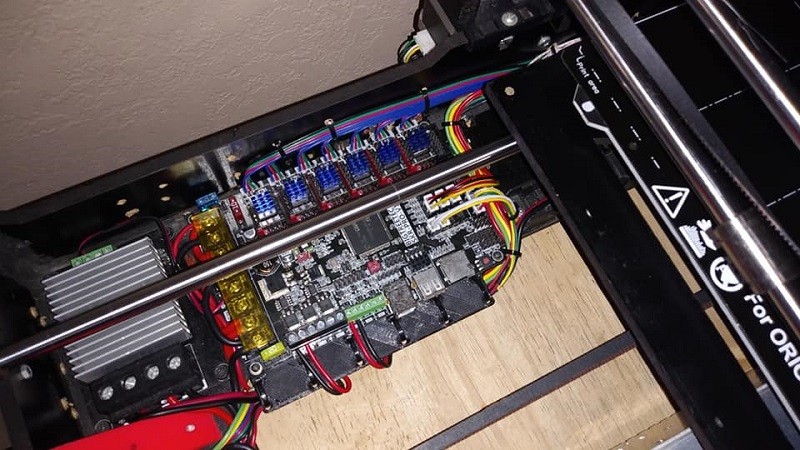

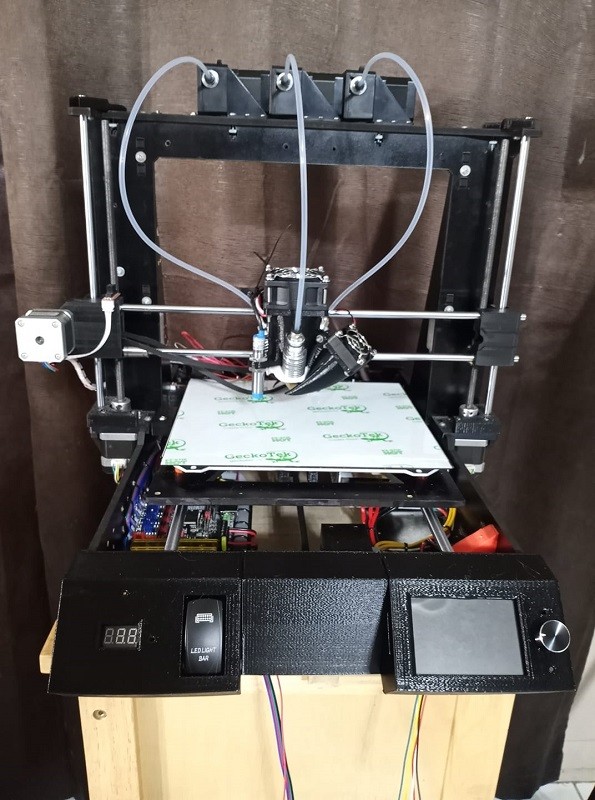

The mainboard is all setup and ready to go. 6 TMC2209 drivers all configured for UART. There are 2 stepper cable plugs on the mainboard for the dual Z motors and there is a splitter hiding at the rear of the frame for the dual Y motors. So despite 5 stepper motors controlling movement on this machine only 3 stepper drivers are working the motion. The other 3 are for E0, E1, and E2. That's 8 stepper motors and 8 stepper motor cables all under a moving bed and here is how all that came out..

-

08-03-2020, 09:48 PM #102

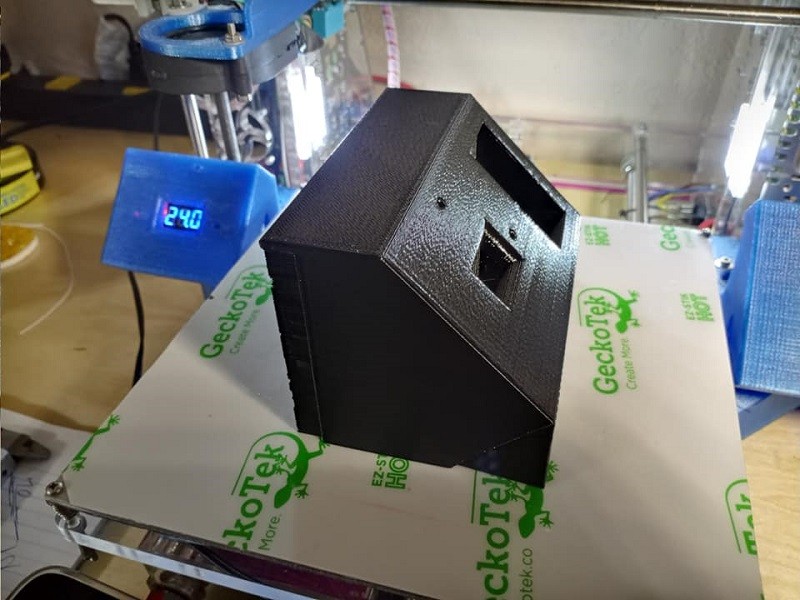

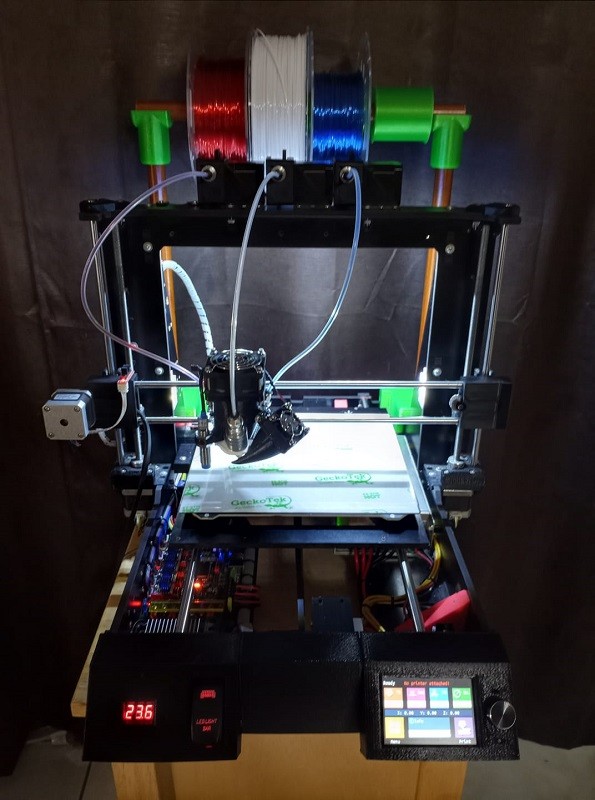

I am getting close to completion on this machine now. When i am done i will upload all the files i made for this to thingiverse and share with all as i did with the other 2. But that is later. Right now 'Old Blue' has finished making the voltage display and light bar power switch mount..

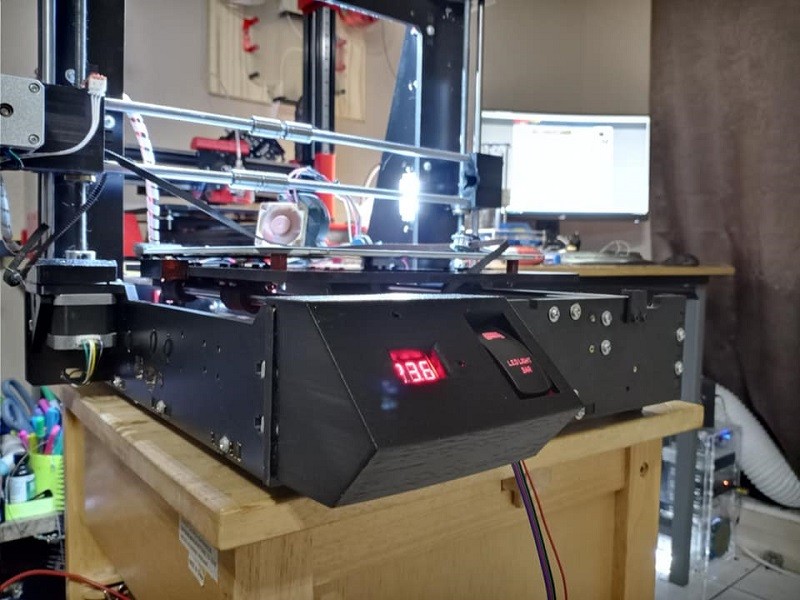

It took 7 hrs to print that part and it printed with a lot of support material. I sliced it with S3D and printed it with PETG at 250c with no cooling fan. After removing all the support material I mounted the lm2596 step down converter with voltage display and the led light bar power switch and installed the assembly on Printalicious. Once i got everything wired up i plugged in the printer and powered it on for the first time since this rework started and i couldn't be happier with what i got so far..

Now I gotta make a mount for the touchscreen with the same dimensions to mount to the other side of the robot and all 3 printers will have a near identical UI setup..

-

08-08-2020, 08:48 AM #103

-

08-12-2020, 09:02 PM #104

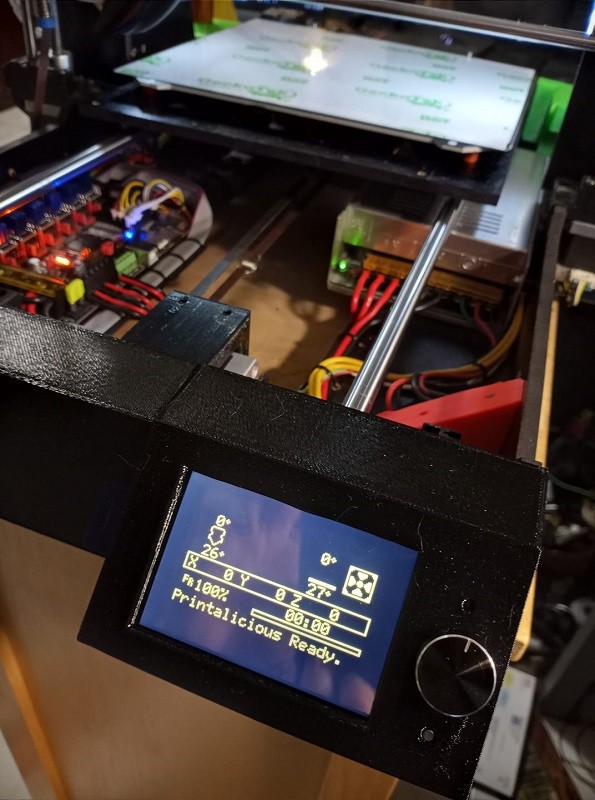

I love these dual mode displays. I remember the crowd and not so long ago that discovered and bought the TFT but had to keep the LCD12864 screen. Always the excuse about babystepping the z offset or something along them lines if i remember correctly. Well these screens have to be wired both ways. That is the 5 pin tft harnes that has =5v, gnd, reset, rx, and tx and also the 2 ribbons that connect the exp1 and exp2 connectors on the mainboard. But once its all together we push in and hold the knob down for 3 seconds and it brings up a menu to let me choose which display mode I want to use. I have my base calibration of marlin 2.0.5.3 loaded in and here is my display in LCD12864 mode..

-

08-12-2020, 10:44 PM #105

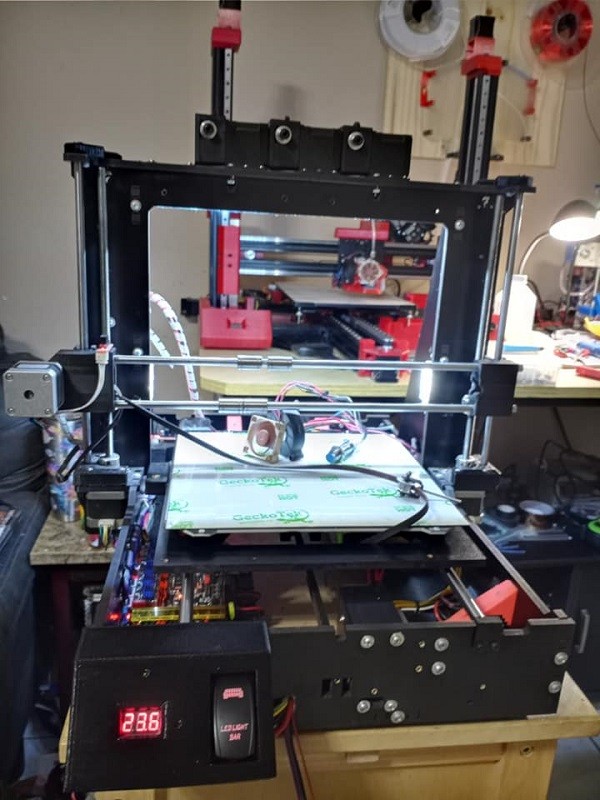

And so this completes all 3 32 bit printer reworks. I now have 2 custom multi material printers. After I am done cleaning my workspace from all the hardware and tools and stuff and put away the soldering station I will turn my focus to understanding how to use S3D with the MMU2S and the Diamond hotend. And then once my machines are printing with multiple materials I will turn my focus to trying to understand how to make multi material objects. Here is my revived 3 Color Mixing Printer completed..

-

08-14-2020, 05:51 AM #106

for me, that's the unpleasant part done and the really fun part of designing multi material prints is to come.

I suspect you probably see it the ither way round :-)

so can actually blend filaments with that setup or just do one at a time ?

-

08-14-2020, 10:32 AM #107Technologist

- Join Date

- Oct 2016

- Posts

- 184

Nice. Interested to see how the color mixing works. I tried it on my clone cyclops hotend with varying results, at least some PLAs weren't mixing, but resulted in a more 'toothpaste' type extrusion. Apparently PETG should mix better, but I didn't try ir, the hotend had too much issues and I didn't have anough patience with it...

About slicers: for MMU2S I think PrusaSlicer is probably the easiest to start with since it the multi-material support is written MMU2S in mind. S3D is harder to get working, at least on my setup where I need to use post-processing sw to add the actual tool change gcode after slicing.

For color mizing I don't know any slicer that supports it. For my tests I wrote a short python port-processor to add the mixing ratio commands per layer.

IMG_20200724_103718.jpgIMG_20200724_103727.jpg

Multi-part desings: if you can read OpenSCAD, I designed some multi-part prints that I use when testing my post-processor: https://github.com/spegelius/3DModel...estmodels.scad

Basically the design process involves designin multiple parts and cutting part y from part x when they overlap, making sure the model origins match so that when imported to the slicer the models are in corrent positions. In slicer then just assing models to proper extruders (in S3D this is a kinda PITA to do properly)

-

08-14-2020, 10:37 AM #108

Ya you seem to know me well at this point. lol. I am so comfortable building because that is all i do all day every day. I am so comfortable here. But we will get it. As for the diamond hotend yes we can mix colors. and there is no backing up one filament before feeding in another. No toolchange at all here. Just start feeding the extruder you want. This is why i had to finish this one before i got too deep into trying to get the MMU2S working. This is easier i think and i will find success here easier. And the MMU2S honestly i will probably get up and going when spegelius gets his MMU2S and shares his gcode with me, lol.

-

08-14-2020, 11:16 AM #109

I am not sure how to make them mix. But i understand we must load translucent filaments for the mixing colors. magenta, cyan, and yellow but all translucent. And I saw a place in marlin 2.0.5.3 to enable mixing extruders which i haven't yet. That kinda sucks about the slicers not supporting the mixing but honestly that is ok for now i guess. one at a time is good to start with. I just read all this here and took off in that direction: https://reprap.org/wiki/Diamond_Hotend

Did you get your MMU2S yet?

-

08-14-2020, 11:43 AM #110Technologist

- Join Date

- Oct 2016

- Posts

- 184

Yep, in Marlin 1.9 I had following:

The virtual extruders are kind of a preset mixing values to use. To use the 16 virtual extruders, in start gcode I defined the virtual tools by assigning the mixing ratios for each. The mixing ratios are what I thought would be good, but they can be anything as long as the total value is 1. So when selecting T5 for example, would drive 21% E0 and 79% E1.Code:#define MIXING_EXTRUDER #if ENABLED(MIXING_EXTRUDER) #define MIXING_STEPPERS 2 // Number of steppers in your mixing extruder #define MIXING_VIRTUAL_TOOLS 16 // Use the Virtual Tool method with M163 and M164 #define DIRECT_MIXING_IN_G1 // Allow ABCDHI mix factors in G1 movement commands #endif

https://marlinfw.org/docs/gcode/M163.html

But this method gives only 16 gradients. The proper way to get full mixing steps is to use M165 in the gcode file.Code:; Virtual extruder 0 M163 S0 P1 M163 S1 P0 M164 S0 P1 ; Virtual extruder 1 M163 S0 P0 M163 S1 P1 M164 S1 P1 ; Virtual extruder 2 M163 S0 P0.5 M163 S1 P0.5 M164 S2 P1 ; Virtual extruder 3 M163 S0 P0.07 M163 S1 P0.93 M164 S3 P1 ; Virtual extruder 4 M163 S0 P0.14 M163 S1 P0.86 M164 S4 P1 ; Virtual extruder 5 M163 S0 P0.21 M163 S1 P0.79 M164 S5 P1 ; Virtual extruder 6 M163 S0 P0.28 M163 S1 P0.72 M164 S6 P1 ; Virtual extruder 7 M163 S0 P0.35 M163 S1 P0.65 M164 S7 P1 ; Virtual extruder 8 M163 S0 P0.42 M163 S1 P0.58 M164 S8 P1 ; Virtual extruder 9 M163 S0 P0.49 M163 S1 P0.51 M164 S9 P1 ; Virtual extruder 10 M163 S0 P0.57 M163 S1 P0.43 M164 S10 P1 ; Virtual extruder 11 M163 S0 P0.64 M163 S1 P0.36 M164 S11 P1 ; Virtual extruder 12 M163 S0 P0.71 M163 S1 P0.29 M164 S12 P1 ; Virtual extruder 13 M163 S0 P0.78 M163 S1 P0.22 M164 S13 P1 ; Virtual extruder 14 M163 S0 P0.85 M163 S1 P0.92 M164 S14 P1 ; Virtual extruder 15 M163 S0 P0.92 M163 S1 P0.8 M164 S15 P1

So to get a gradient sweep with 2 colors is to add following codes per layer

M165 A0 B100 ; layer 1

M165 A1 B99 ; layer 2

M165 A2 B98 ; layer 3

etc.

(For 3-color mixing, add C: M165 A1 B99 C0)

https://marlinfw.org/docs/gcode/M165.html

Sadly no MMU2S, no info or anything. Might ask about the status, it's been quite more than 3 weeks already...

Reply With Quote

Reply With Quote

Printing time- Is this right?

09-13-2024, 07:51 AM in General 3D Printing Discussion