Results 1 to 7 of 7

-

04-18-2020, 02:21 PM #1Student

- Join Date

- Sep 2018

- Posts

- 10

Need Help moving 48x48 inch printbed

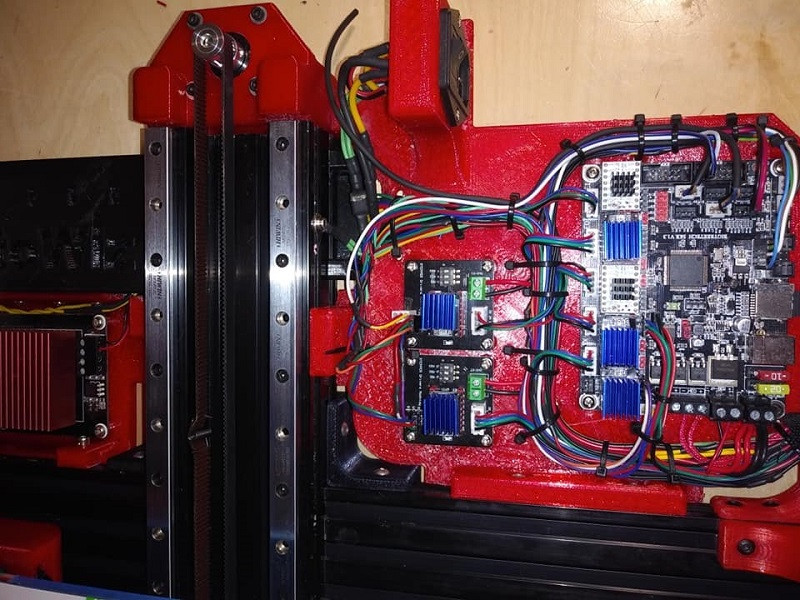

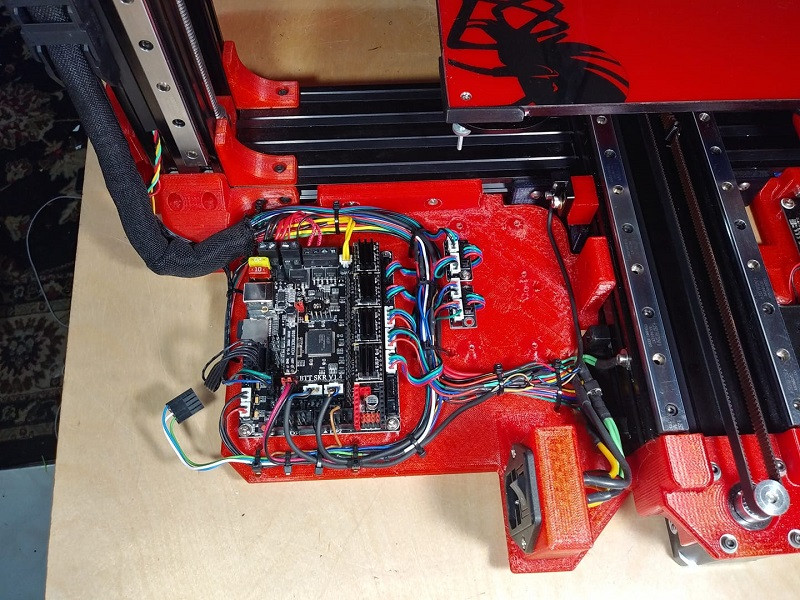

Hiya All,I'm making a large 3D printer but I'm having issues moving the printbed. My current goal is to have a ballscrew on each side with a 1A stepper driving each of them. Ill offset the weight with some constant force springs pulling it up. My trouble is powering all 4 of the 1A steppers off of a single motor driver. I'm using a smoothieboard and only have room left for one more stepper driver which I would hope wouldn't be a problem given all of their inputs should be the same. So how should I power 4 1A steppers off of a single stepper wired to my smoothieboard? I would very much appreciate suggestions for a sufficiently powerful driver as well as wiring ideas.Thanks!

-

04-19-2020, 09:53 AM #2

get a better board.

You need at least 2 stepper drivers as I think a standard driver is ONLY rated for 2 amps and they recommend you stay clear of the maximum anyway.

Nope you need something like a duet or duet clone board. You can add as many stepper drivers to that as you like.

You might be able to add a breakout/daughter board to a smoothieboard that will add extra drivers.

No idea but you can do that with a bog standard ramps board, so why not a smoothie ?

How are you attaching the bed to the rails - assuming you're using linear rails - wheels, would seem inaccurate for such a large bed.

Also curious how you'll attach springs given that as the bed moves the springs will also need to move, and the motors will be moving the weight of the bed plus springs plus spring frame attachment.

Can't visualise how that can work.

Also - why are you moving the bed at all ?

The sensible option would be a moveable gantry for the y axis and x and z axis attached to the gantry.

Have alook at the 3dp printers - that's how they do it.

https://www.goprint3d.co.uk/3dp-worktable.htmlLast edited by curious aardvark; 04-19-2020 at 10:23 AM.

-

04-19-2020, 11:28 AM #3Student

- Join Date

- Sep 2018

- Posts

- 10

The only moves in the Z axis. It starts at the top near the gantry which moves in X and Y and lowers as layers are extruded.

-

04-19-2020, 01:37 PM #4

so a standard cartesian setup.

Check to see if you can add a daughter board to the smoothie board.

-

06-10-2020, 10:33 PM #5Student

- Join Date

- Sep 2018

- Posts

- 10

My current plan is to get a TMC 5160 driver which supplies 4.4 Amps max. I'm going to use this to power 4 pancake steppers rated at 1 amp, 3.5 ohms. I'm not sure if I should wire the steppers in series or parallel. I'm researching but any help or pointers appreciated.

-

06-11-2020, 04:47 PM #6

I like the idea of the 5160. If not there is usually a breakout of pins right next to each stepper socket on the mainboard that you can tap into and run some wires to a remote or aux stepper driver board. Get a splitter for each so 2 steppers can drive 4 motors and get a pair of TMC2209's.

-

06-11-2020, 04:55 PM #7

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help