Results 11 to 20 of 36

Thread: GEEETech i3 32bit Rework

-

01-04-2020, 12:02 PM #11

The titan aero on this printer is genuine E3D. And while it does have a 24v heater cartridge, it is a 40 watt part with the red wires. These heaters work fine. They have for a long time and never had a problem. However, E3D sells these high precision 30 watt cartridges with the green wires. And they still get up to the high temps just fine. Also I am installing a Micro Swiss plated 0.25mm nozzle..

-

03-11-2020, 06:46 PM #12

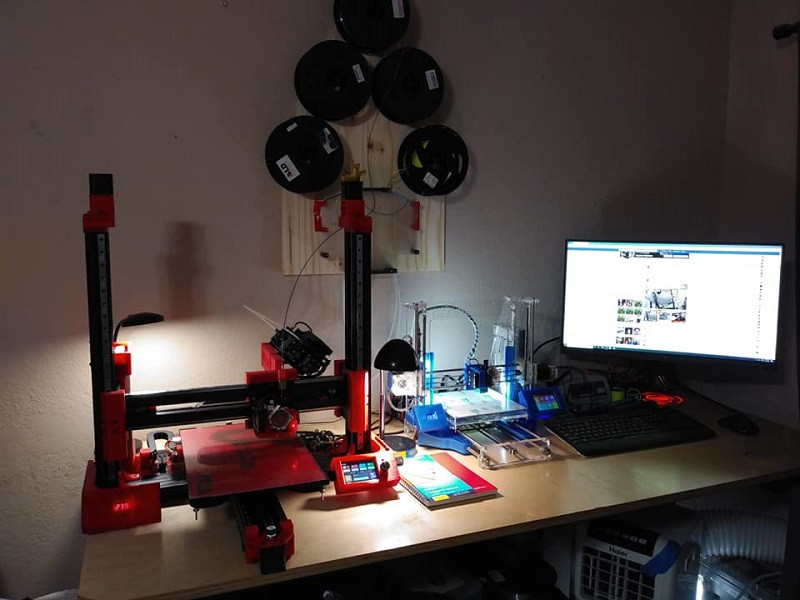

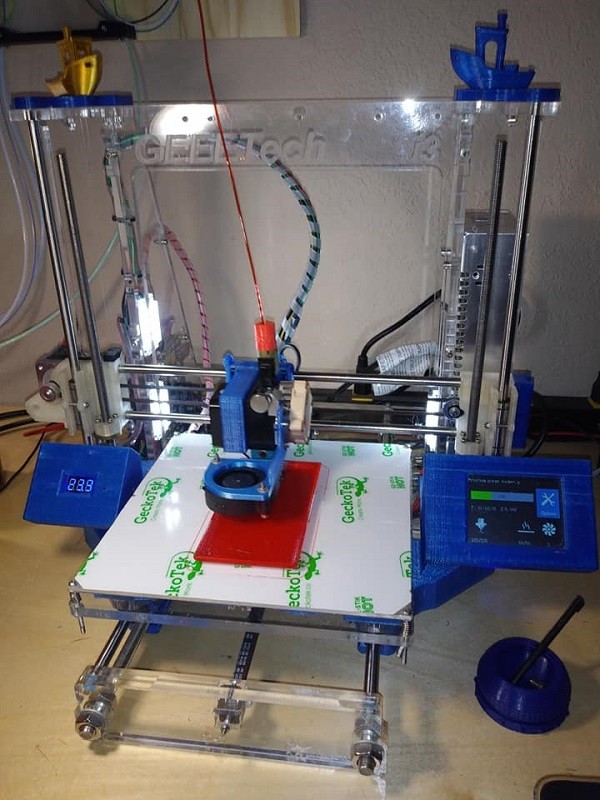

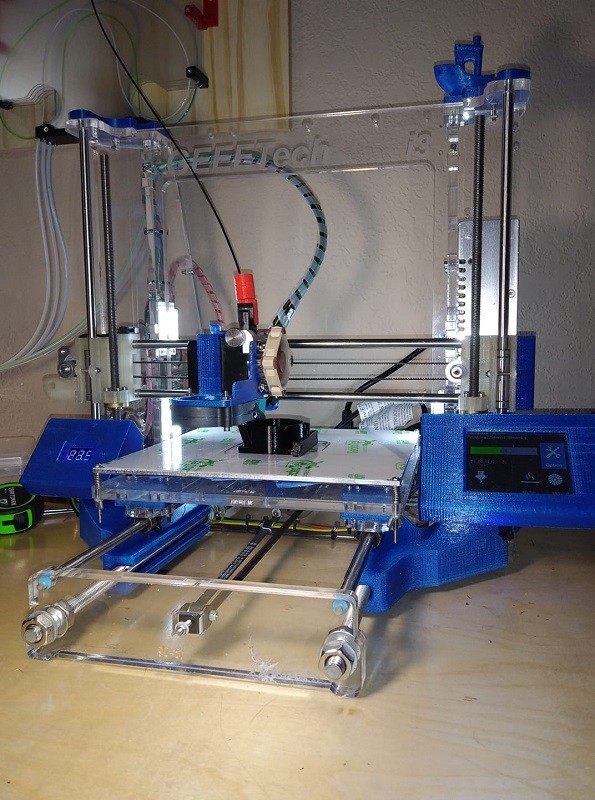

Well i got this thing all wired up and powered on. The only thing it is missing is a layer fan. I have the power wires for it ran and even have a few fans that i could use. I just need to design the part to mount it to. But for now, here is my new old GEEETech i3 pro B..

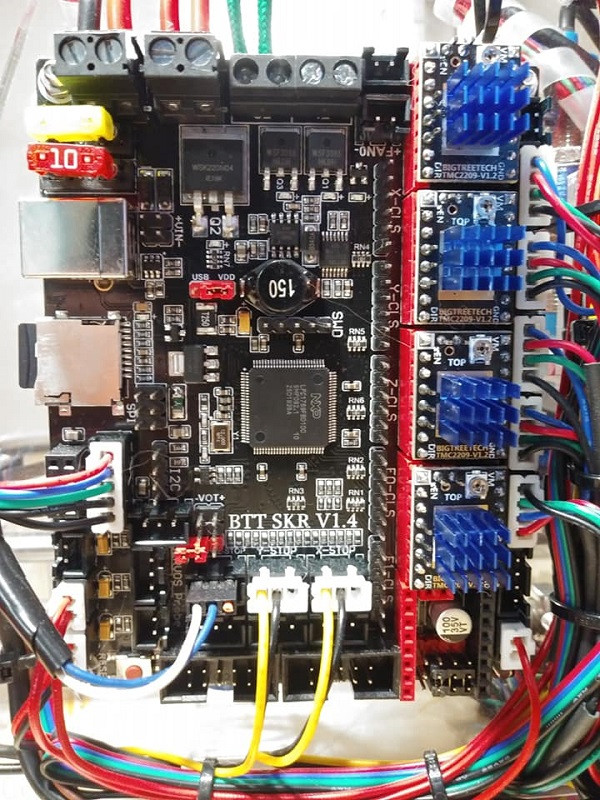

Just to recap this printer is a 350watt 24v power supply, an SKR 1.4 Turbo with 4 tmc2208 v3.0 stepper drivers, an MKS tft32 color touchscreen, buck lm2596 step down converter with voltage display, genuine E3D titan aero with high precision 30watt heater cartridge, a Micro swiss 0.25mm plated nozzle, 0.9 degree stepper motors everywhere but Z, gates pulleys and reinforced belts, an aluminum heat bed with NPN proximity switch for Z, and a Noctua 40mm fan for the extruder. I am very happy with how all this came out. And it really looks the part sitting next to my other printer rework..

-

03-11-2020, 07:56 PM #13

I have a thingiverse going for these reworks here: https://www.thingiverse.com/AutoWiz/designs

-

03-12-2020, 09:43 PM #14

-

03-25-2020, 08:11 PM #15

-

03-26-2020, 08:48 AM #16

what did you do to the printbed ?

Looks like unheated acrylic - that can't be right ?

-

03-26-2020, 10:15 AM #17

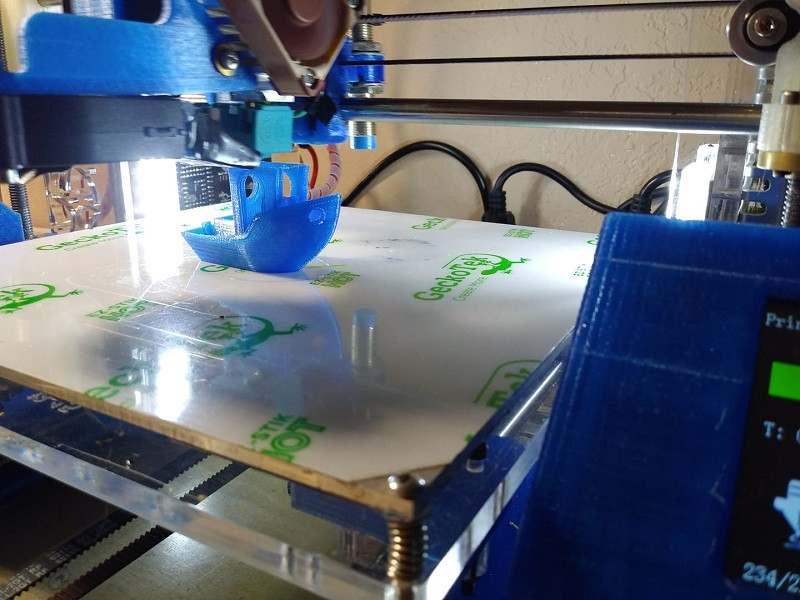

That's the gecko tek build surface. It works really well. I printed out a part cooling fan for this but havent got it working yet. Once it is working i will make another attempt at printing that iris box.

-

03-27-2020, 05:36 PM #18

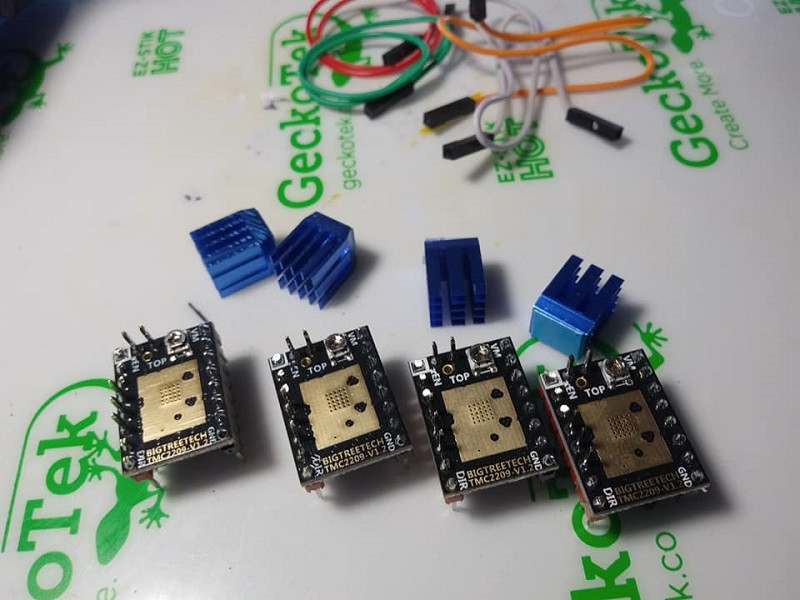

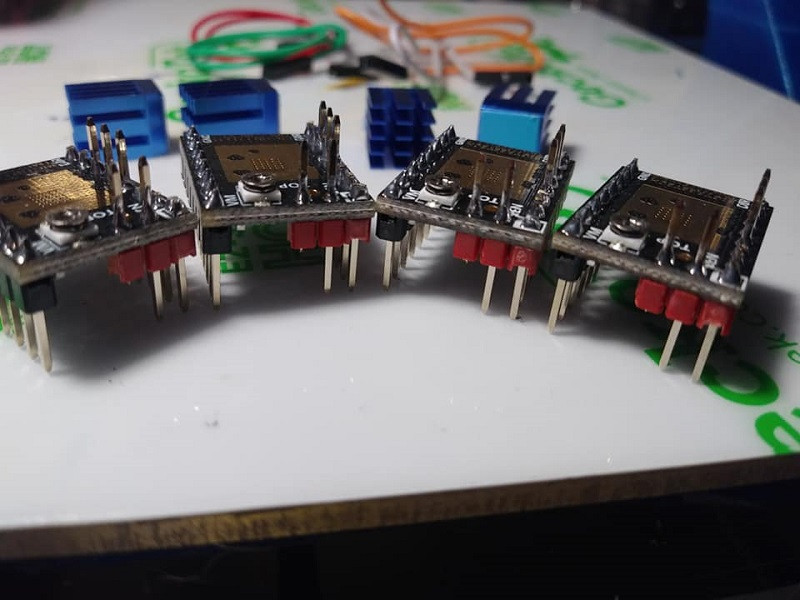

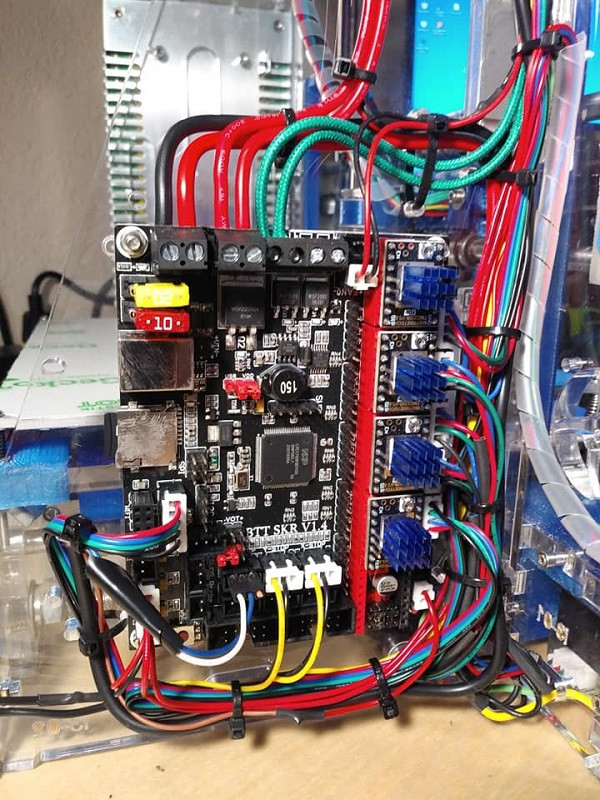

So I have been thinking and while everything is running good, I am just not happy with one of the solder connections I had to make to the underside of the TMC2208 v3.0 drivers to make them run in UART. I have had no problems with this, it is just that I had to solder it under a magnifying glass because it they are such tiny solder pads that need to be soldered. One of them the solder looks close to another soldered connection. Again everything works and well, I am just afraid it might one day short off. This paranoid fear has driven me to one more upgrade for this printer. 4 TMC2209 v1.2 drivers..

I am extremely happy with these drivers in my other printer. Not only can they handle more power but they run cooler while doing it. Which means no active cooling needed. Or at least that is how I understand it. Nothing needs to be soldered for UART however these driver are capable of sensorless homing. My printer is already built and wired around end stops so I do not care for stallgaurd. So before I can plug these drivers into the SKR 1.4 Turbo mainboard I need to remove 1 pin from each stepper driver. This pin..

I am extremely happy with these drivers in my other printer. Not only can they handle more power but they run cooler while doing it. Which means no active cooling needed. Or at least that is how I understand it. Nothing needs to be soldered for UART however these driver are capable of sensorless homing. My printer is already built and wired around end stops so I do not care for stallgaurd. So before I can plug these drivers into the SKR 1.4 Turbo mainboard I need to remove 1 pin from each stepper driver. This pin..  Setup for these drivers from the tmc2208 already run in UART is painfully simple. And running UART on the SKR boards really allows for a clean appearance..

Setup for these drivers from the tmc2208 already run in UART is painfully simple. And running UART on the SKR boards really allows for a clean appearance..

-

07-07-2020, 08:22 PM #19

So 'Old Blue' here is now the workhorse that will make the parts to help me realize multi material printing from 2 angles. Currently This awesome machine is printing out a purge bucket I designed that will sit behind the screen on my MMU2S rig..

After this I will load the black PETG and get busy on making the 3 mounts for them 3 titan extruders for the Diamond hotend rig. This is now my only single filament printer.

After this I will load the black PETG and get busy on making the 3 mounts for them 3 titan extruders for the Diamond hotend rig. This is now my only single filament printer.

Last edited by AutoWiz; 07-08-2020 at 10:47 AM.

-

07-08-2020, 09:41 PM #20

Last edited by AutoWiz; 07-08-2020 at 09:49 PM.

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help