Results 11 to 18 of 18

Thread: Manufacturing Or Fabrication

-

02-02-2020, 10:03 AM #11

Well in the face of building a cnc plasma cutting table, I can maybe just buy a cheap one. I mean they aren't that bad. And if I supply my own plasma cutting tool, they are even cheaper. What do you guys think of this: https://www.youtube.com/watch?v=fdsCEx_YaJk&t=

-

02-02-2020, 11:45 AM #12

The only thing holding me back at this time is a place to put this. Or i would already have it: https://store.langmuirsystems.com/pr...BoCxDMQAvD_BwE

-

02-05-2020, 06:17 AM #13

looks good :-)

Seems weird only having the gantry supported at the one end - but guess it's not a problem.

But for under $2000 - with the extras, seems like a good buy to me.

-

02-05-2020, 07:06 PM #14

I need a sponsor. Or a silent investor. Or even friends that live close by and share in my interests and visions that can share in the cost. And i can find the freedom in fabrication that i so desperately seek. Have you seen this man's youtube channel, CA? I can't get enough of this Colin Furze. I can only dream of being so free to create: https://www.youtube.com/watch?v=QT8QkEK0X8U&t=

-

02-05-2020, 07:10 PM #15

In fact the very first project I have planned for this cutting and welding cart is this inset metal brake from this video right here: https://www.youtube.com/watch?v=Ggy1DHwAh_0

-

02-12-2020, 01:22 PM #16

you are aware of what you do for a living, right ?

How is fabrication equipment not both a genuine business expense and a valid piece of cost reducing equipment.

Now what you do with that equipment out of hours - that's your business :-)

-

03-10-2020, 04:38 PM #17

-

03-17-2020, 05:13 PM #18

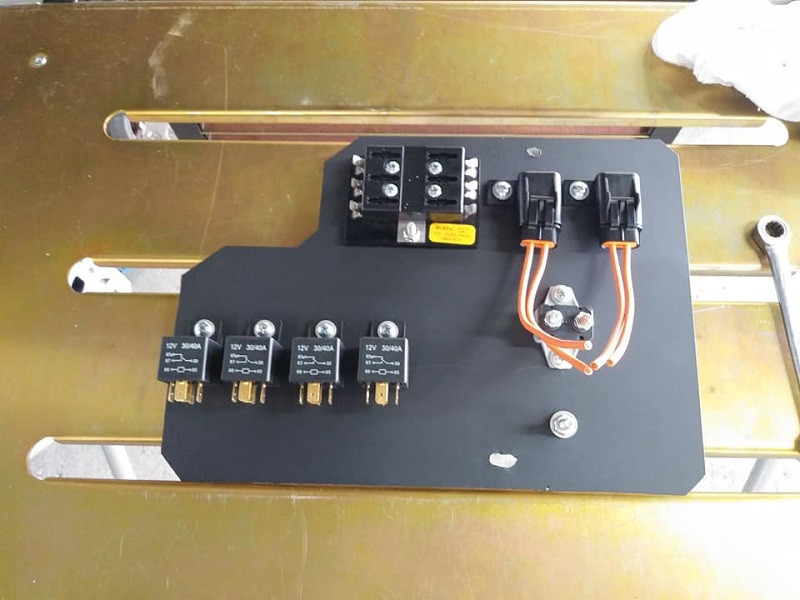

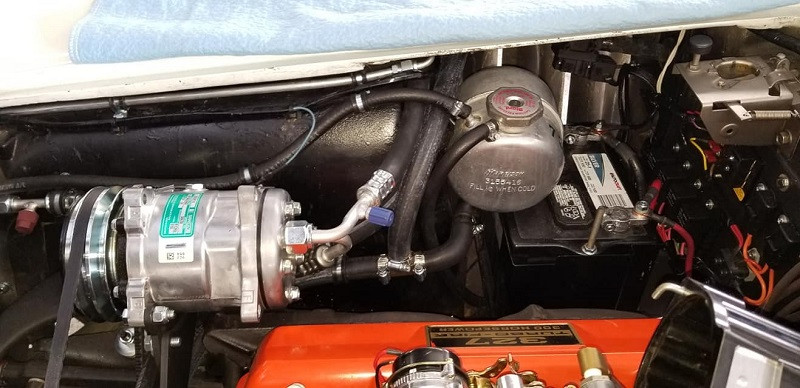

That answer depends greatly on your definition of 'good'. If by good you mean learn how to prep your metals, attach a ground strap within a foot of your welding area, and get good penetration with a MIG so you can get a job done, then maybe not too long. Definitely less if you are used to soldering as it is very much the same process just scaled up a bit. If you want to be good enough to make the pretty welds we all love to look at on social media this can take a while and requires lots of practice like playing a band instrument. And if you want all of your welds to pass X-ray tests then you should have a bunch of experience laying the pretty welds. One of my first jobs in the automotive industry was at a Midas muffler shop 20 years ago, now. There I learned to weld and also to use a pipe bender. And today I can make stuff like this: https://www.digitalcorvettes.com/thr.../#post-3085545 . And this: https://www.digitalcorvettes.com/thr.../#post-3441096 . And also this: https://www.superchargerforums.com/t...ring-gto.3135/ . Or even this: https://www.superchargerforums.com/t...n-a-7-0l.3130/ .

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help