Results 211 to 220 of 354

Thread: 370mm X 250mm X 300mm

-

12-17-2019, 07:30 PM #211

Oh man that hurts. I have a mainboard and the stepper driver expansion boards mount the steppers oriented opposite to what is on the mainboard and then the pot is on different sides on the TMC2208 and LV8729 drivers and I installed 3 drivers backwards on the mainboard. I let the smoke out. Now the drivers are dead, with them removed the mainboard is dead. The screen is not turning on and I hope it is just because of the lost connection to the mainboard. So this job is on hold while I wait for a new mainboard and drivers. It stinks in my living room now. But hey, If your gonna be dumb and stupid, you gotta be tuff. I gotta go open a window.

-

12-17-2019, 08:40 PM #212

Well how about that. The SKR 1.4 and SKR 1.4 TURBO are out and available on BIQU's website. It has the same footprint as the 1.3 so it is what I ordered. While I wait on shipping for anybody interested in the latest version of the 32 bit SKR board that is still right around $20 here is a link: https://www.biqu.equipment/collectio...31198920999010

-

12-19-2019, 05:41 AM #213

speed - if it won't print as good at 150mm/s as your other printers do at 50mm/s - then, well it's mostly for nothing :-)

Go on load up an iris box and crank the speed right up

I'd drop you the link to the iris box - but thingiverse is currently a bit poorly :-)

try this: https://www.thingiverse.com/thing:1817180

I don't count benchy's.

Make something both practical and a right bastard to print is my test. And then see just how fast you can make it.

I think my current best for an 80mm (widest point of base) smooth running iris box is just under 4 hours at 0.16 layer height.

This is also just about the best test of clean retractions I know of.

I struggle with the 60mm version in the link - so that would be an even better test.

I reckon Brian ought to be able to knock one of these out in under 1.5 hours.

These boxes are great for little screws and stuff that won't fall out when you knock them on the floor (like i do lot).

Plus about the best thing to show people to illustrate how 3d printing differs from injection moulding.

Once working I usually add a drop of 3-1n-1 oil to the base of the 'flaps' with the box closed. Then work it a few times to fully lubricate the mechanism. Amazing just how smooth they'll open and close after that.Last edited by curious aardvark; 12-19-2019 at 05:54 AM.

-

12-19-2019, 11:15 AM #214

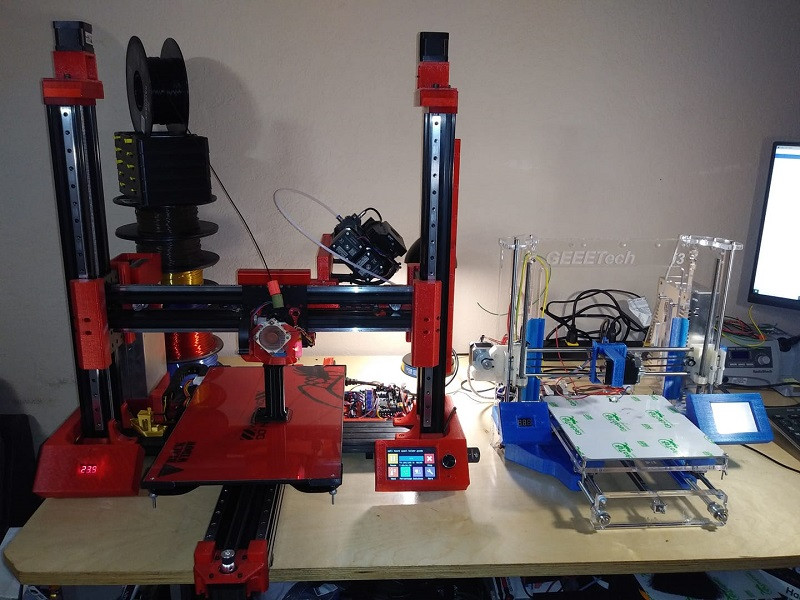

I have been learning on the fly as I build and play. I chose a starting point and gave it a go and have walked away with some important knowledge to share. The LV8729 drivers are great for the 1.3A stepper from E3d that comes with the titan and titan aero. But them drivers max at 1.5a and most nema17 stepper motors we use start at 1.68a. On a loose, broken in, or worn printer maybe this might work. But on my machine with the high end guides with preload I have had a few of the lv8729 drivers fail and have replaced them before deciding to go back to the TMC2208. What this is teaching me is that my large format printer needs a 0.5 or 0.6mm nozzle and .3mm layer height. And it can build big things fast and accurately. I think I need to rework my geeetech i3 to have a 32 bit skr mainboard, put the LV8729 drivers on that (it already has all 0.9 degree stepper motors and a titan aero), get a 0.2mm nozzle and make that my precision machine to chase the 0.025mm and less layer heights or make detailed miniature action figures or something. I think that is what i am doing. So much so that i have already started designing braces for the Geeetech and ordered a second SKR 1.4 mainboard.

-

01-01-2020, 07:52 PM #215

Tracking shows both SKR 1.4 Turbo mainboards are inside the country. I should have them soon and I can get back to this incredible machine. One thing that is different with the SKR 1.4 over the 1.3 is it now natively supports dual Z stepper motors and has a second connector tied to the Z stepper driver. For strength and because I have such a heavy gantry I am going to be using TMC5160 drivers. This has had me thinking if I need 2 stepper drivers per axis or if just one TMC5160 is fine to drive 2 stepper motors on each axis? This sure would let me clean up my electrical. while I do not have a breakout for a second connector on each axis I sure can get or make some adapter harnesses or solder the wires together myself. I think I still have a few days to mull how I want to proceed. I do want a clean look.

-

01-02-2020, 04:40 PM #216

-

01-05-2020, 07:06 PM #217

Oh Yes! Finally, this printer is back in the game. The SKR 1.4 Turbo is a new board with a new chip for the SKR series. Where the 1.3 and 1.4 have LPC1768 running at 100mhz the Turbo has swapped this for LPC1769 @ 120mhz. While I can not yet speak on the performance benefits of this I have a lot to say about setting it up. The first time around and just recently I bought a SKR 1.3 and at that time there was not an official release of marlin 2.0 yet and I setup and installed marlin 2.0 bugfix. Now there is an official release of marlin 2.0 and there is also a marlin 2.1 dev that can be had. In all of these versions of marlin the only one that had the SKR 1.4 turbo listed in the boards tab is a version linked from biqu.equpiment's website. it is marlin 2.0 official but is is a special version of it from biqu for this board that I guess came out after the board list for the official release was done. BUT WAIT, SKR 1.4 Turbo is also not listed in marlin 2.1 dev? So I guess it will be added to a later version of it. Maybe when we get to 2.1 bugfix we will see it. This matters because there is no other boards or even a viable way to tell marlin you are using LPC1769. Anyways, the Multi Widow lives. It died after printing 3 of 5 wall mount spool holders I designed for the mmu. Right now it is working on the other 2 and then I will get the 5 spools and filament buffer mounted and we will start down that path.

-

01-05-2020, 09:17 PM #218

-

01-06-2020, 06:33 PM #219

Alright CA i am printing your Iris Box right now. I am using the speeds that came with the marlin 2.0 firmware and the settings that came with the Prusa slicer. I have not made any changes to any of the speed settings yet. I am open to suggestions or screenshots of better settings i might try. Or i will find an answer from youtube or google. This iris box for me is set for 3hrs and 2 mins. But it is looking good so far..

-

01-07-2020, 06:06 AM #220

be interesting to how easy it is to get working. You cut the tabs underneath. Then work a small screwdriver around the edge of the base to loosesn the base. Then cross your fingers and twist :-)

3 1/2 hours sounds about right. So you don't know the actual print speed ?

what diameter/width are you printing it at ?

Brian definitely looks like he's about to leap at you ;-)

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help