Results 131 to 140 of 354

Thread: 370mm X 250mm X 300mm

-

10-20-2019, 06:24 PM #131

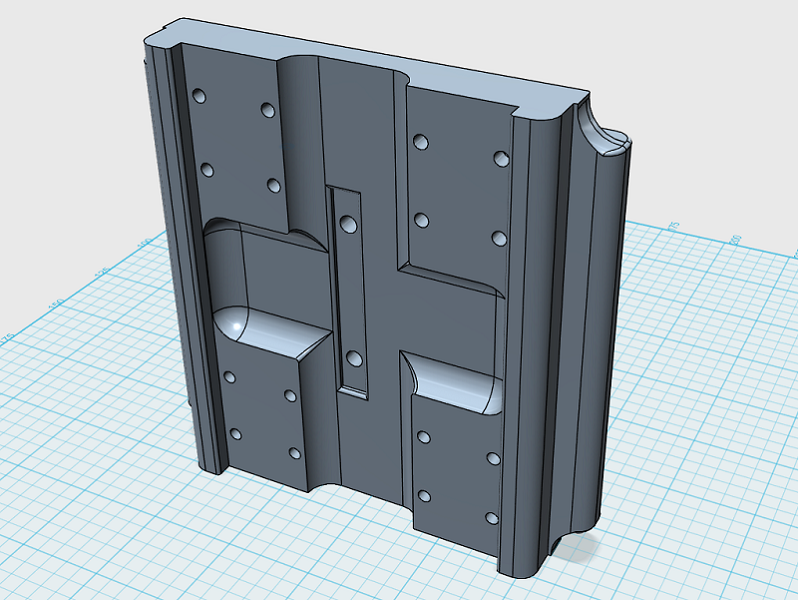

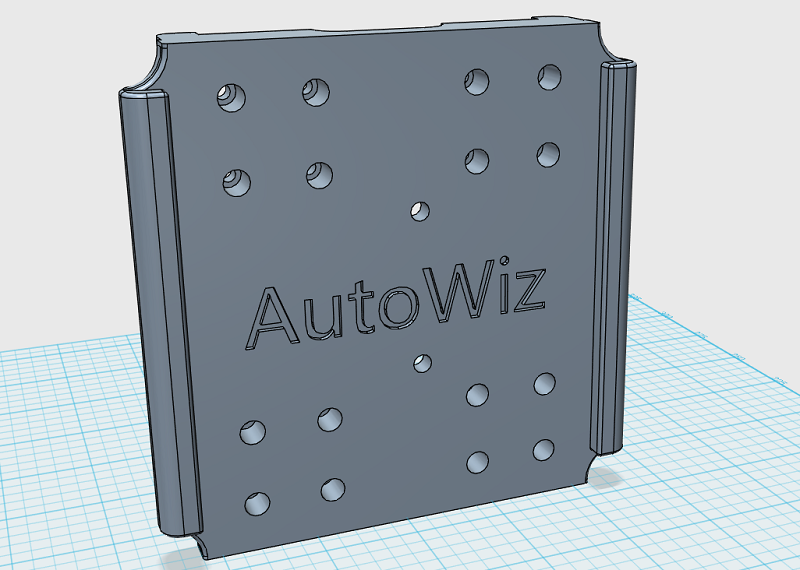

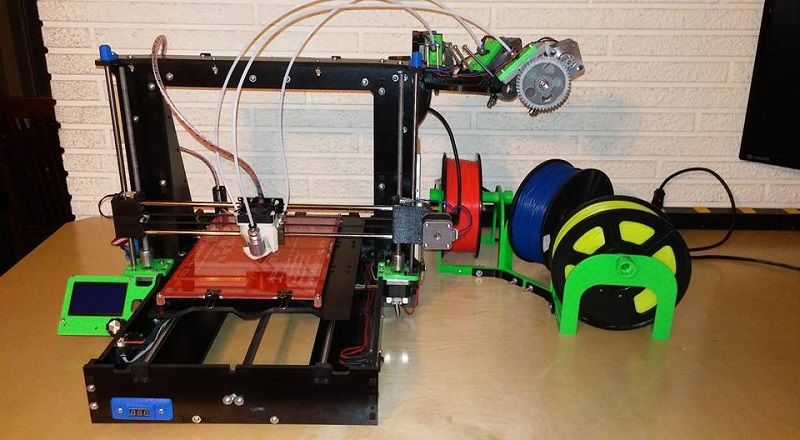

Ok so I am trying to cope with the linear guide costs but I already have my correct parts for Y. So I am working on completing that axis. I am turning the bed sideways so instead of 370 or 380 X 250 I can get the full 400 X 250 build volume. Also I am applying linear guides so I need a very specific piece to attach the mount/ base plate for the heat bed to the linear guides. And here is my design..

-

10-21-2019, 07:28 PM #132

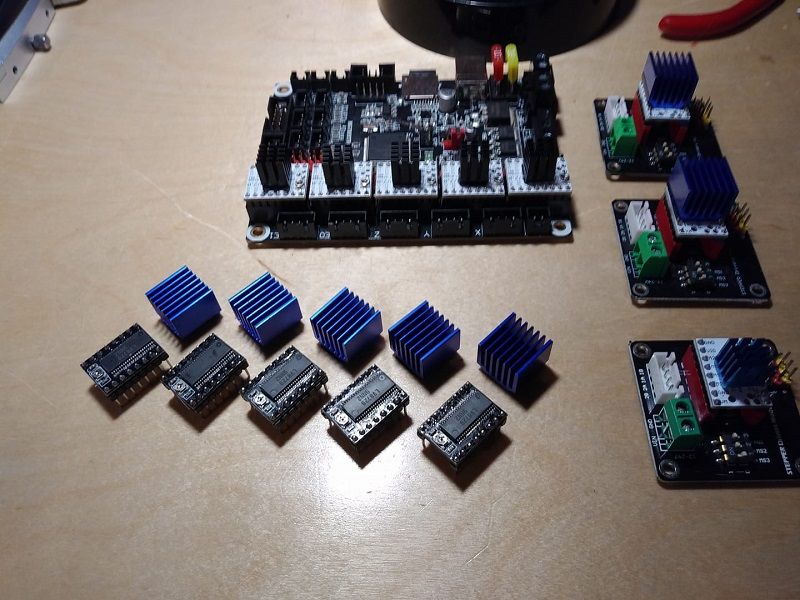

My new stepper drivers showed up. I got 5 LV8729 drivers that I have every intention of running in 1/128 micro stepping. 2 for X, 2 for Y, And 1 for E. Z already has so many steps per MM that I do not know if it will be beneficial for the extra cpu effort required so I am going to run 2 TMC 2208 drivers for the Z motors. Because they are silent at 1/16 micro stepping..

-

10-30-2019, 09:13 PM #133

I learned a hard and expensive lesson on linear guides. The right answer is expensive and to be perfectly honest anything less and you are better off saving your money. I bought the cheap ones first. And then I bought the genuine HIWIN. And while my butt hurts immensely, life has never been so good..

-

10-30-2019, 09:19 PM #134

-

10-30-2019, 09:20 PM #135

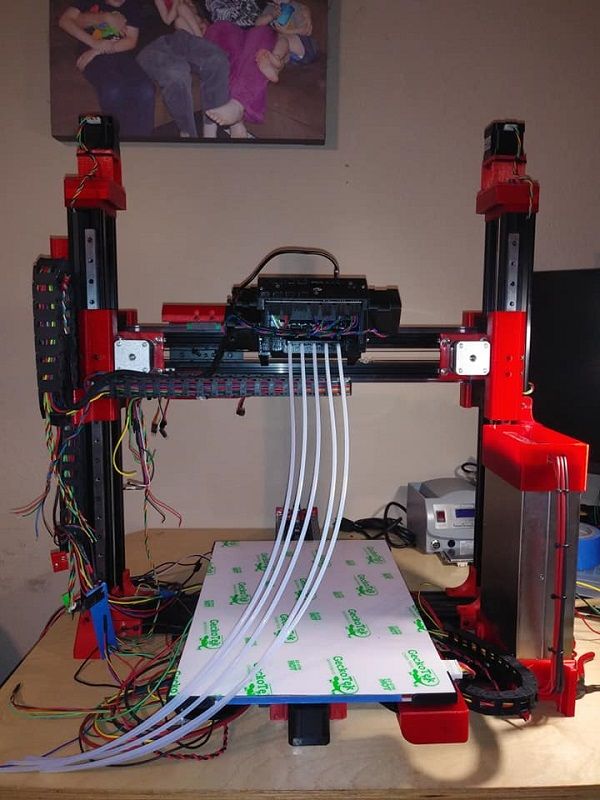

So my bed is going to move more now that it is turned sideways. 400mm travel instead of 250mm. And with the MMU2S unit hanging off the gantry it is clear that the ptfe tubes will have to make sharp bends to avoid the bed at the start of prints. So I am thinking about making a bracket and hanging the MMU2S off the gantry still but just at 90 degrees so the PTFE tubes are off to the side..

-

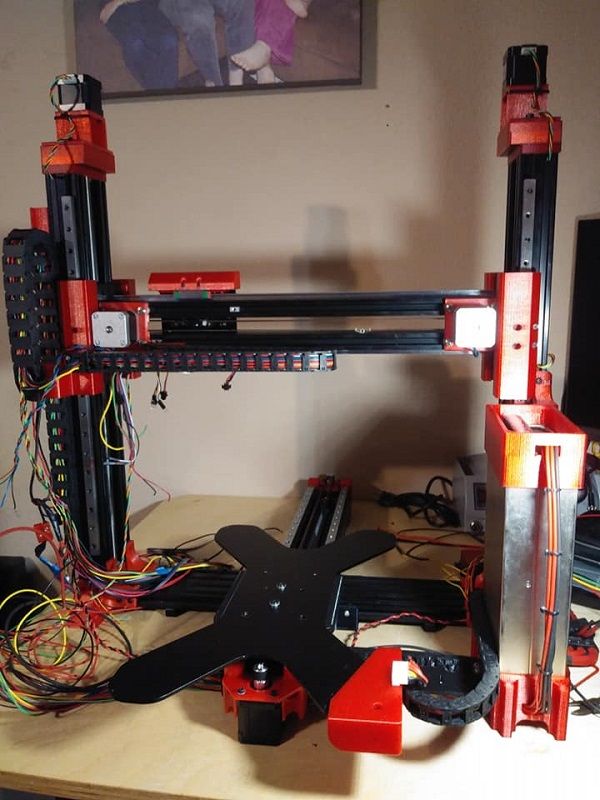

11-02-2019, 12:04 PM #136My last order of HIWINS is on the fedex truck out for delivery right now. I am literally standing on my porch staring at the watch I dont have on my wrist and tapping my foot. lol. And then I got some backtracking to do to get the gantry off and the z motors off so I can change the 4 rails for Z. Hopefully at some point here today I will produce a picture of my Black Widow with 8 HIWIN rails screwed to it.

-

11-02-2019, 06:33 PM #137

so what made you go for the mmu2 over the mosaic palette 2 ?

On balance the mosaic would seem the better option as it will blend colours As well as do multi filament selection, rather than just select single filament types like the mmu2. Also only a couple hundred bucks more. Or about 6 inches of linear rail :-)

-

11-02-2019, 07:51 PM #138

I am going after multi material from 2 different angles. As far as multi material goes, the MMU2S takes in 5 filaments and it costs $300. For twice as much your mosaic takes in 4. This will be my printer to print in many different filaments. When I am done with this build I will most likely hunt down a little monster and apply a diamond hotend to it with my knowledge from today and get a mixing printer with 3 colors. I mean, lets just be real for a second about mixing. All colors come from 3 primary colors. Don't you remember this?

3 primary colors. So then if we are mixing what is the 4th filament for? If we are mixing we need 3. If we are chasing multi material then we can have more than 4. And for hundreds of dollars less I might add. And from a big name like Prusa Research.Last edited by AutoWiz; 11-02-2019 at 07:56 PM.

-

11-03-2019, 03:10 PM #139

I respect you, your thoughts, and your input CA. And as such I have done some further research on the palette 2 and I still feel the same. But for a new reason I want to share with you. For it to take in 4 filaments and feed one out to the hotend and be able to handle mixing can only mean that this machine has it's own hotend built in and it is melting and squeezing out new 1.75mm diameter filament on the fly. While this is a cool feature on the surface my 24v printer is already up to a 600watt power supply. We must consider power consumption when we are dealing with machines that can run for literally days at a time. Of course this is all my thoughts and ideas on the subject this side of a working model or prototype.

-

11-04-2019, 06:03 AM #140

the 4th element is for white. Think about inkjet printers.

4 colours because the white is already present in the paper and you need black to adjust for shades.

Although - it would actually need 5

In life, the white is represented by - well light itself.

In 3d printing you need white and black to make shades of colours. The three primary colours themselves will mix any colour - but the lightness and darkness of shades will be fixed. The white and black are there to change the 'brightness'.

So ideally for a full colour mixing fdm setup you would have black, white, red, yellow and blue.

Quite how you would blend actual filaments together - no clue.

The best option at the moment are the inkjet solutions like the xyz davinci colour uses. A white filament that's coloured with the three primary colours and a black.

That said, looking at the mosaic, it doesn't do blending after all. Pretty much the same as the mmu2s, one colour at a time.

But I do like the way it cuts and shunts the filament into the system as it actually connects each piece of filament to the next with a proper melted joint.

I guess the advantages over the mmu2s would be mainly in speed as you just get a continuous length of filament rather than all the stopping and starting and retracting with the mmu2s.

Each length is precision cut and joined to the next in line.

So no it isn't actually extruding new filament - but it is heat joining the different lengths.Last edited by curious aardvark; 11-04-2019 at 06:10 AM.

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help