Results 81 to 90 of 102

-

07-09-2019, 05:05 AM #81

After some judicious wobbling I have found the problem !

The bearings that run up and down the smooth guide rods are simply clipped into the plastric assembly.

There is nothing holding them steady and they rock in the sockets. Presumably they should have been secured by cable ties.

So It looks like I'll need to remove the extruder assembly again and wither drill some holes for cable ties, or glue the buggers in.

Autowhiz, I noted you'd 3d printed your parts - got the stls anywhere ?

-

07-09-2019, 04:58 PM #82

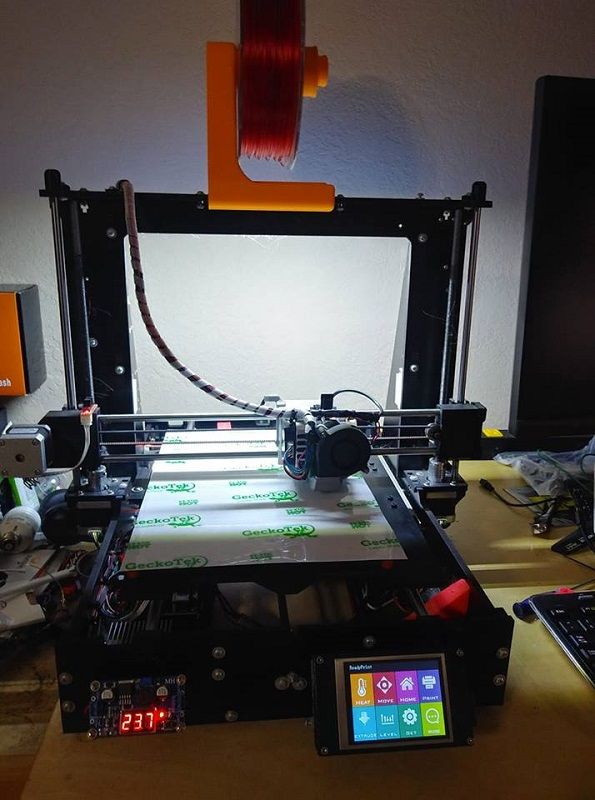

What would you like? I have gone back a few pages and seen your z bearings do not look secured to the plastic. They are a different style than what I am using. If you look at the picture of mine on the last page you will see I have a bolt that goes through my plastic to hold them bearings tight in place. Those are official Geeetech X carriage parts downloaded and printed from thingiverse. I have them on my home made printer also. But because that frame mounts the z rods too close to the frame I had to mirror the images before slicing and then mount the x carriage backwards so those ends would fit on my frame..

-

07-09-2019, 05:08 PM #83

Also you should note the orientation of the filament spool. The other way is functional but far from preferable. And as you reach the top of your build height you might end up breaking some filaments. Which just blows at the end of a really long print that would see the max build height achieved. I have had such great results from each and every time I applied a second motor to an axis that I am thinking now about a printer with no idler pulleys. 2 stepper motors on opposing ends of each axis. This printer will use 7 stepper motors and 7 stepper motors drivers for 1 extruder. I think 10 if we want to use the MMU2.0 stuff which I very much do. Can you imagine a printer with 10 stepper drivers? Sounds far fetched, doesn't it? I think i'm gonna do it. For this effort I will just print another motor end for the x axis and replace the idler end with it. This is such an incredible hobby because there is so much freedom to just be creative here.

-

07-09-2019, 05:27 PM #84

Here is the thingiverse with the printed parts from geeetech for the i3. you can mirror them print them how you like put the motor on whichever side you like facing whichever way you like. These parts take a bolt and even without the bolt they hold the bearing all the way around: https://www.thingiverse.com/thing:989245/files

-

07-12-2019, 06:08 AM #85

cheers - frame looks identical - so the parts should fit.

I can see what you mean about the orientation of the filament spool. that's a fairly easy fix, but can wait for the moment.

Although if it were printing to height, then there wouldn't be an issue. At the moment I tend to put the z axis at the top at the end of a print and that does give a long length, but if it were printing and going up slowly, there wouldn't be a problem. Plus I'd need to move the screen - which I can't be arsed to do :-)

um, 7 - 10 stepper motors for a single extruder i3 ?

why ?

Okay, re-read the post. So a motor at each end of a belt. What benefits would that give ?

If the motor weren't perfectly in sync it would cause more hassle that you might save. You'd need to make sure that all the wires to the paired motors were identical lengths. Okay electricity passes pretty quickly through wire, but it's a measurable speed and you don't need much difference to effect a print.

I guess if you had a very large printer, it would reduce strain on the belts and pulleys - but can't see any other reason.Last edited by curious aardvark; 07-12-2019 at 06:17 AM.

-

07-12-2019, 11:16 AM #86

counting equal steps to 2 motors has been perfected since the first i3 printer came about. This is no problem. The benefits of this conversion will be speed and strength without artifacts in the print from heavy axes being slung back and forth, to and froe. It is the difference between pushing or pulling depending on which way you are going vs. pushing AND pulling in each direction. I ran 2 motors for my Y axis on my Black Widow printer with the big heavy 400x250 heatbed with 3mm borosilicate glass plate. It works amazing. no more skipped steps and I was able to raise the print speed as well. 2 motors on an axis directly translates into 2x holding torque on that axis.

Another great place for this conversion would be if you had a 12v printer and wanted to run the silent drivers in stealthchop. a second motor and driver on a given axis would go a long way towards correcting for the lost holding torque.

-

02-18-2020, 10:26 AM #87

well it's been a while.

Main reason being the x-axis endstop has ceased to work, and the z-axis endstop is so frigging awkward to adjust, I've been waiting till I've got the incentive to sort things out properly.

So As the firmware is so bloody awful and the screen and buttons are barely functional - I'm going for a major (from my parsimonius point of view) upgrade.

I'll make an easily adjustable z endstop, and change the board to an mks sbase 1.3 that's been hanging around my workshop for a couple of years. Also comes with a 3.2inch colour touchscreen with a full size sdcard slot.

I've even got a wifi module for the screen - but that can be played with at a later date. For now I just need it properly functional.

I think the screen can do the whole restart after power outage bit as well.

I've tracked down the smoothieware configuration file that lets you use the second extruder motor as a second z-motor.

Looks like a few wires mirrored from the actual z acis connector and I should be good to go :-)

I've got to the point now where I need a larger print volume and this is the best candidate for the job. Plus it's actually faster than the delta, and hopefully with the new board and stepper controllers - should be as good a quality as well.

More as I go.

Now given that all parts were paid for a good while ago and were for an entirely different project - I'm not counting cost ;-)

Cheating - probably, but it's all about what it costs ME - not someone else :-)

I'm sticking with smoothieware - it's just so easy to adjust things on and the only marlin I've seen is the one already on this machine and it's just truly bloody awful.

Updating smoothieware and the config is as simple as putting the files on the sdcard and booting up.

None of this messing around with horrible 3rd party software nonsense :-)

Plus the configuration file I found was already set up for my screen.

Right - off to try and work out what pins I need to mirror and work out how to do it :-)Last edited by curious aardvark; 02-18-2020 at 10:37 AM.

-

02-18-2020, 10:55 AM #88

Also there is a network socket on the board which I can connect to the k40's server and put the printer on my workshops native wired network.

Once all this is done - I'm curious to see how well the prusa slicer will drive the beast. Given that it is an actual prusa clone(ish) - well, considerably more of a clone than 90% of current i3 machines anyway :-)

-

02-19-2020, 01:41 PM #89

well I plugged everything in, and powered it up.

No smoke ! - Result :-)

The dual z motors work - steps are clearly off, but they both turn together :-)

That said all the axis appear to be reversed.

Endstops don't appear to have registered and axis home in the opposite direction to the stops.

Hmmm.

But the screen works.

And nothing explided or caught fire.

So I think it's mostly a case of working through the configuration file and seeing what's what :-)

-

02-20-2020, 11:32 AM #90

Tracked down the problems - for some reason it's not updating the config file.

So it still thinks it's a delta.

Tried all the stuff it says on the various wiki's.

Just not updating settings.

:-(

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help