Results 71 to 80 of 102

-

06-30-2019, 12:12 PM #71

cable guide is the arch. printed without supports.

Just made abasic cap for the screw and stopped it from popping up with cable ties.

We'll see how long they last, there's zero wobble when you move it up and down. So theoretically, things should have improved.

currently printing a cap out on the ctc - the other two were on my delta.

see if there's any difference in the z- banding.

Couplers:

-

07-01-2019, 09:00 AM #72

Well, while the printer looks better, the vertical striping is a LOT worse !

In fact if you look at this, you'll that rather than just striping, it's formed an actual screw thread.

That should be a smooth surface, I have no clue what's causing this - thoughts ?

-

07-01-2019, 10:08 AM #73Student

- Join Date

- Sep 2018

- Posts

- 11

It's not an accurate method,but I used a set square to level my gantry. I align one side on the bed then measure the gantry height on both sides. But obviously if the bed is off, the levelling is going to be a bit off too.

-

07-02-2019, 04:26 AM #74

good idea. I reckon if I move it up and measure the distance between the rods and the bottom of the top frame, that should help. Obviously you need to level the bed after.

In fact I'll do that now :-)

Well it was way off. But pretty sure that won't make any difference.

When you move the y-gantry up and down, the whole extruder mechanism visibly rocks back and forth.

I'll see if I can video it.

It's not related to how level the gantry is.

And the screws don't wobble any more. Could it be some sort of misalignment between the smooth guide rods and the screws ?Last edited by curious aardvark; 07-02-2019 at 05:16 AM.

-

07-02-2019, 02:36 PM #75Student

- Join Date

- Sep 2018

- Posts

- 11

That threading is weird.

Are you easily able to wobble the gantry by hand? If so, perhaps tightly wrapping cable ties around the linear bearings and the bracket might help to steady everything.

The linear bearings on mine are perfectly snug with the guide rods, but the bearing itself seems to be a little lose in their bracket.

Actually I'll try this now on mine to see if it helps.

-

07-02-2019, 02:46 PM #76Student

- Join Date

- Sep 2018

- Posts

- 11

Scrap that idea. There's no way of wrapping the cable ties round.

-

07-02-2019, 09:33 PM #77

You need to remove those grey printed pieces from the top of your leadscrews. You have precision linear rods for the z axis to follow. The lead screws should touch only at the stepper motor and at the x axis they are lifting. I cut mine to just below the frame. Install your spacers to set things up and get the leadscrews close to straight, sure. But take them out before you run the printer. And when you watch the leadscrew run out like it does, you should smile big and proud at the energy you are keeping away from your linear rods.

-

07-02-2019, 09:38 PM #78

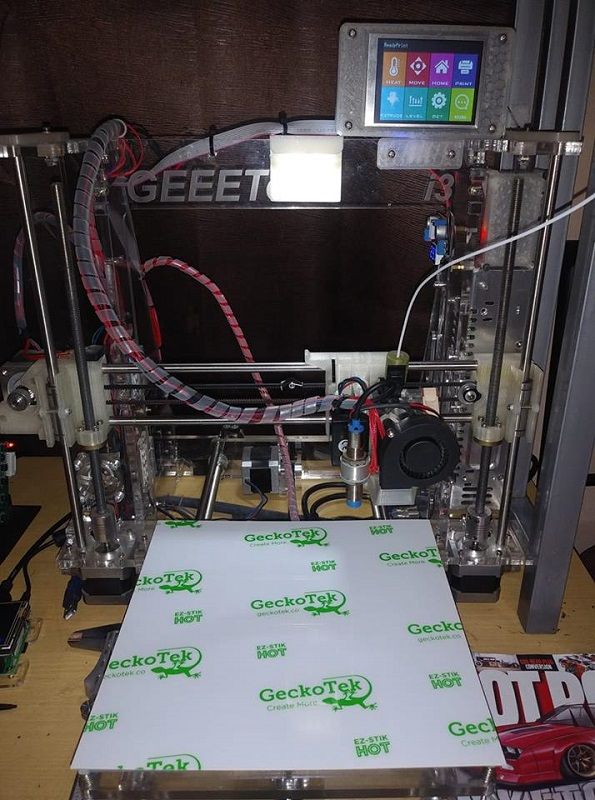

Like this and it prints incredible..

Because there are linear rods and there are leadscrews and leadscrews generally are not a thing of precision. Because they had a tool twisted all up and down the rod to cut the threads on it. So they need to be allowed to do their thing. clamp at the stepper, threaded through the axis and left out in the open.

Because there are linear rods and there are leadscrews and leadscrews generally are not a thing of precision. Because they had a tool twisted all up and down the rod to cut the threads on it. So they need to be allowed to do their thing. clamp at the stepper, threaded through the axis and left out in the open.

-

07-04-2019, 03:34 PM #79Technologist

- Join Date

- Jul 2017

- Posts

- 193

AutoWiz is helping with the z-wobble issue. I just wanted to add the the flashing issue on the red anet board IS caused by the lack of a bootloader on the board. There are youtube videos out how to flash the bootloader, then you can flash marlin ( or others ) using the arduino IDE.

-

07-06-2019, 05:56 AM #80

to be fair I run all the controls from simplify3d, and since I removed the usb cable extender, I stopped having connection issues.

The only thing I use the onboard control panel for is running a print from the sd card.

To be fair, it is the only thing you can practically use it for.

If I could flash it, then marlin is the absolute last thing I would use.

It is my only marlin printer and the only one where the firmware isn't worth the silicon it's written into.

In what universe do you make a 3d printer firmware that won't even load filament from the control panel ?

The other 4 firmwares are all excellent, and all different :-)

Right, so remove the caps and let the screws wobble, but keep the couplers.

And yes, I think the extruder assembly can be wobbled by hand.

I'll have to see why.

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help