Results 41 to 50 of 132

Thread: My 3 Color Mixing Printer

-

01-13-2017, 07:31 PM #41

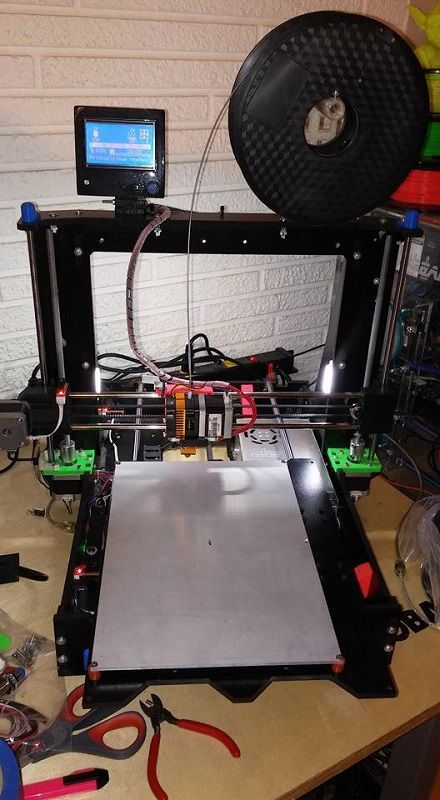

I have decided to apply this to the worst performing printer first so I still have 2 working machines to aid in this effort. The aluminum plate looks good on my home made machine..

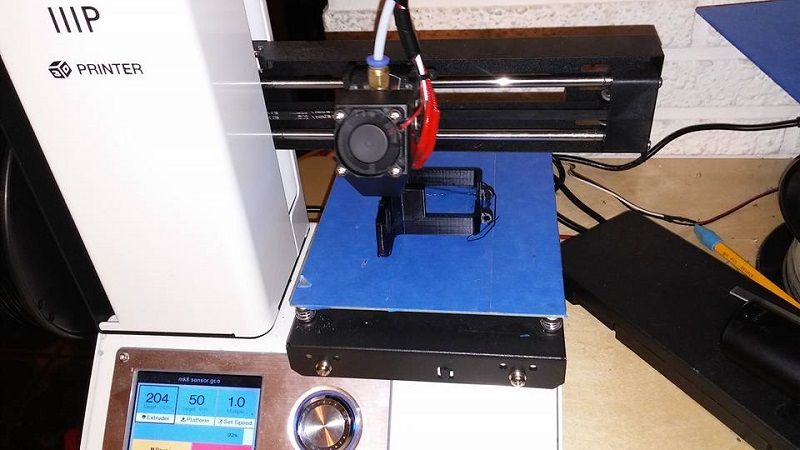

I have decided for the time to stay with the mk8 extruder at least until it is printing as good as the geeetech i3. So I have the monoprice mini printing out a simple mount that will attach to the nema17 stepper motor and hold the sensor..

-

01-16-2017, 05:33 PM #42

-

01-16-2017, 05:51 PM #43

I needed a 300x200 print bed for a specific project which I can now take. A while ago I put a double din android head unit in my car that is only meant for a 1.5 din radio. I made it fit but it is less than pretty..

So I made a few pieces trying to get something that will fit and hide the ugly. The printer is doing real good and the aluminum bed is sweet. Here are the first few bezels I made..

Once I had the basic shap and size right I switched to the black and rounded the edges and junk and printed this..

And while it is not exactly attractive itself it does look better than what it was before..

I will probably remake this piece a bunch more until I get it even better but that black bezel was 230mm wide.

-

01-20-2017, 04:30 PM #44

-

05-07-2017, 01:26 AM #45Student

- Join Date

- May 2017

- Posts

- 16

Very nice project. I find it kind of funny that you mention doing a double din radio in an older corvette with the 1.5din opening. I just did the same thing a few weeks ago and just lots of fileing and fitting, though your car is in much better shape then the one I had to work on

-

05-07-2017, 01:59 AM #46

I enjoy my new path to making parts. Didn't always used to be that way. My carputer project was a great example of how I used to have to build before I discovered 3d printing:

http://www.mp3car.com/forum/general/...al-time-tuning

-

08-03-2017, 09:54 AM #47

Coming back to the topic of a 3 color mixing printer, check this out:

https://ultimaker.com/en/blog/49783-...0|%20Ultimaker

In the future, Cura will implement functionality for creating full-color prints made with halftoning.

-

08-03-2017, 04:23 PM #48

yay! so I wasn't retarded. Just ahead of my time. Hopefully by the time that comes to the mainstream we will have better mixing extruders.

-

06-26-2018, 10:53 PM #49

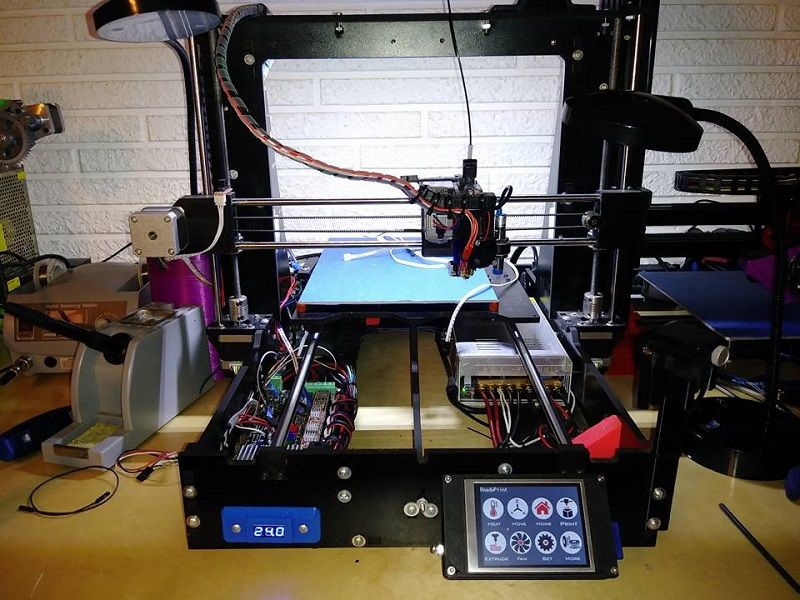

So here we are almost a year after the tragic failure of my multicolor printer project. And I just want to say that this machine has evolved into a great machine.

I am happy with the end result of this machine. But looking back I now understand the problems I was having. I was struggling with and didn't understand a heat creep issue. The fan that came with the ebay diamond hotend was way insufficient and after a short time of printing the filaments that were not in use the longest were melting in the cold end. Sadly it is too late for printilicious to go back to a 3 color printer. But I might try making a new machine now that I know it was a simple problem I was choking on last year.

I am happy with the end result of this machine. But looking back I now understand the problems I was having. I was struggling with and didn't understand a heat creep issue. The fan that came with the ebay diamond hotend was way insufficient and after a short time of printing the filaments that were not in use the longest were melting in the cold end. Sadly it is too late for printilicious to go back to a 3 color printer. But I might try making a new machine now that I know it was a simple problem I was choking on last year.

-

06-27-2018, 05:31 AM #50

'evolved' is the right word !

Half expect it to get bored, sprout arms and legs and go look for stuff to print :-)

The main problem i see with the bezels, seems to be that you print with the part on display the 'rough' top, if you printed them the other way up then the bit on display should be the smooth 'bottom'.

Failing that some fine sand paper anda little black spray paint would also do the job :-)

did you ever give your mate the one you made from scratch ? If so, has he used it ?

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help