Results 1 to 10 of 13

Thread: 3D Printing for My Day Job

-

07-16-2017, 10:10 AM #1

3D Printing for My Day Job

First off I just want to say I have one of the coolest day jobs on this or any planet. I build, tune, and test custom high powered corvettes every day. Our website: http://www.corvette-performance-expert.com/ . For me 3D printing is a new path to making parts for the stuff I build. This legendary vehicle I built before I discovered 3D printing: https://www.superchargerforums.com/t...ring-gto.3135/ . I sometimes reflect on that job and think on how it could have been even better if I had this ability at the start of that job. So now that I have 4 heavily modified printers and the means to be serious about taking on big projects with 3D printing. I wanted to share some early examples of applying this to my automotive trade.

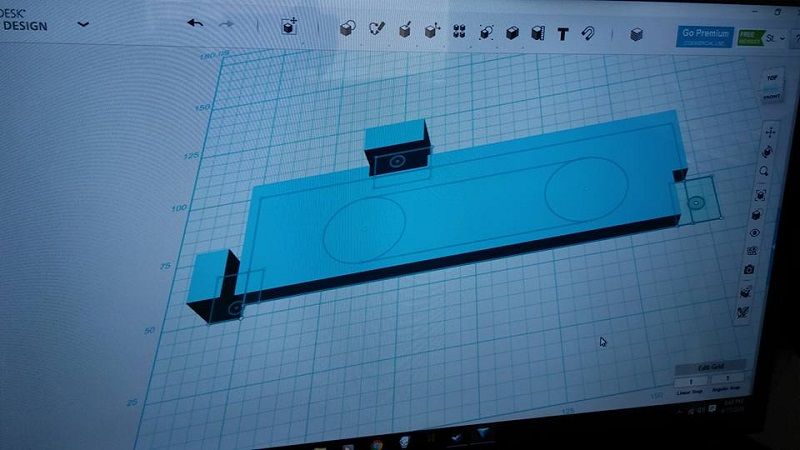

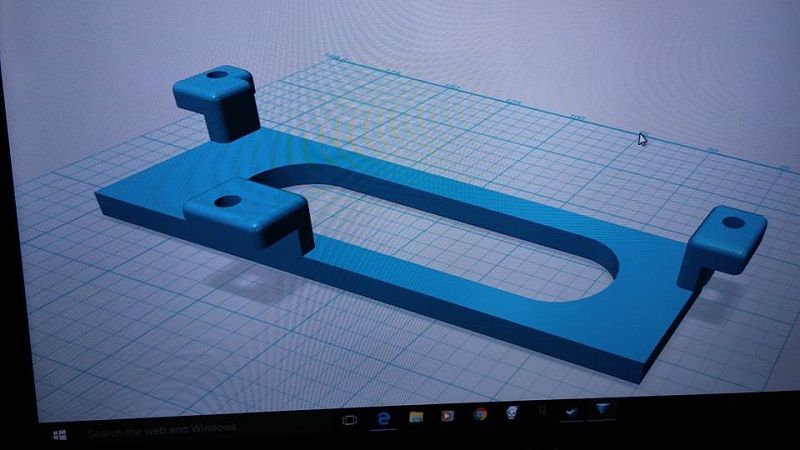

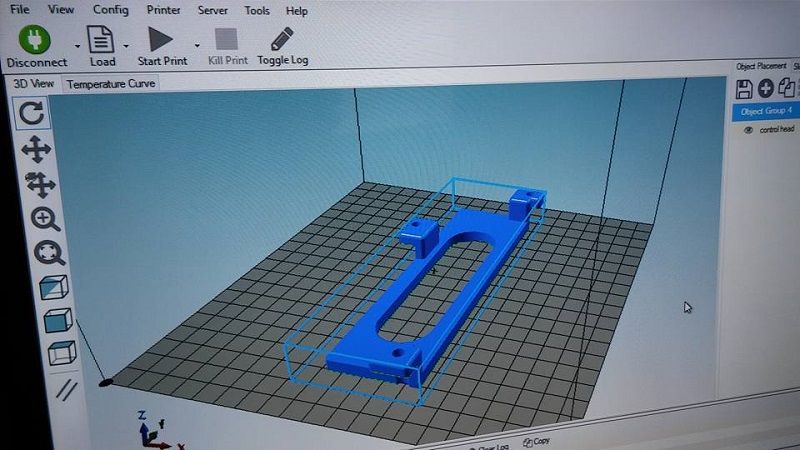

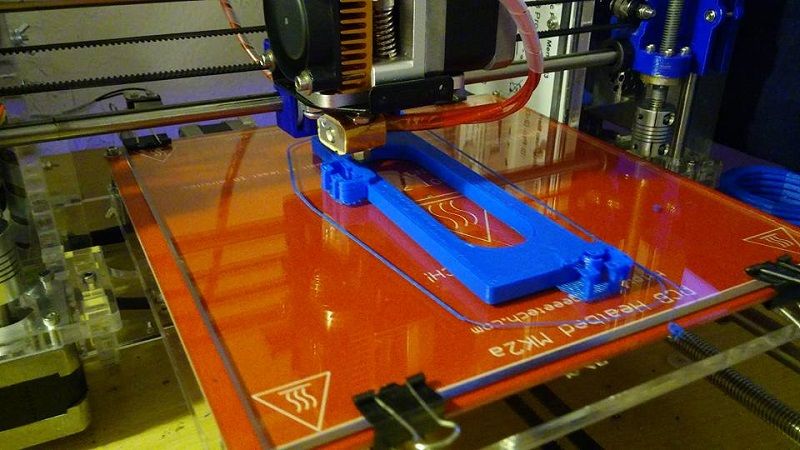

We are primarily a restoration shop. And as such the 3rd generation(C3) of corvette (1968-1982) is our biggest customers and also our bread and butter. At any given time in our shop is at least 1 c3 corvette with the body off. Air Conditioning was a big problem with these cars as it was an afterthought. These cars were made for performance not creature comforts. So we are a vintage air dealer and installer as it is the most functional a/c upgrade option for these cars. However the 1978-82 cars had a slight variation in the dash design that made these kits not compatible with those years. The control head mounting was one problem. So I came up with a design that would use a universal vintage air control head..

And of course it is a perfect fit..

Last edited by AutoWiz; 07-16-2017 at 10:42 AM.

-

07-16-2017, 10:18 AM #2

-

07-16-2017, 10:28 AM #3

Then there is this completely and utterly over the top PD blown 1967 Corvette roadster I am actively building right now. This car is truly the peak of my career thus far. It can be seen here: https://www.superchargerforums.com/t...n-a-7-0l.3130/ . And in a little bit more detail here: http://www.digitalcorvettes.com/foru...d.php?t=278842 . For this car so far I have had to make bezels to fit the undersized aftermarket clock and also to house the mp3 control head and tire pressure monitor. While the clock is done and right, I might still go through a couple more revisions for the tpms. Here is where I am at right now..

-

07-16-2017, 10:26 PM #4

pla for mock ups abs for the final draft.

-

07-17-2017, 05:51 AM #5

-

07-19-2017, 08:47 AM #6Student

- Join Date

- Aug 2015

- Location

- Wisconsin USA

- Posts

- 27

That is indeed, a 'cool' job!

-

07-21-2017, 10:00 PM #7Student

- Join Date

- Jul 2017

- Posts

- 42

very very cool. Quick question. That blue piece looks very nice. Shiny and pretty smooth right off the printer. Any special brand of filament or treatment?

Just curious, my biggest hurdle to making 3d printing a regular part of my business is quality of the print.

-

07-22-2017, 04:31 AM #8Engineer-in-Training

- Join Date

- Jan 2016

- Posts

- 326

The blue piece is metal part of the car. AutoWiz printed the black pieces for the clock and for the mp3 control head and tire pressure monitor.

-

07-22-2017, 05:34 AM #9Student

- Join Date

- Jul 2017

- Posts

- 42

I mean the first couple pics, first post. The blue accent piece for the fan controls you printed. It came out looking great. I'm seeing now the awesome pic is of the bottom side. I need to get a glass bed for sure to get surfaces like that.

Still curious if you use particularly high end or specific brand of filament for that glossy look I'm seeing in the photoLast edited by Nepherael; 07-22-2017 at 05:40 AM.

-

07-22-2017, 07:23 AM #10Student

- Join Date

- Jul 2017

- Posts

- 42

yeah I know. I print with both but his part is coming out looking pretty slick compared to mine whether PLA or ABS. I'm assuming it's a filament quality thing. If he's installing these in vettes I'm down to print with the same stuff he is. I am currently just printing with super cheap ($13/kg) filament for the learning process.

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help