Results 1 to 10 of 101

Thread: Network Printers

Threaded View

-

06-23-2017, 08:43 PM #11

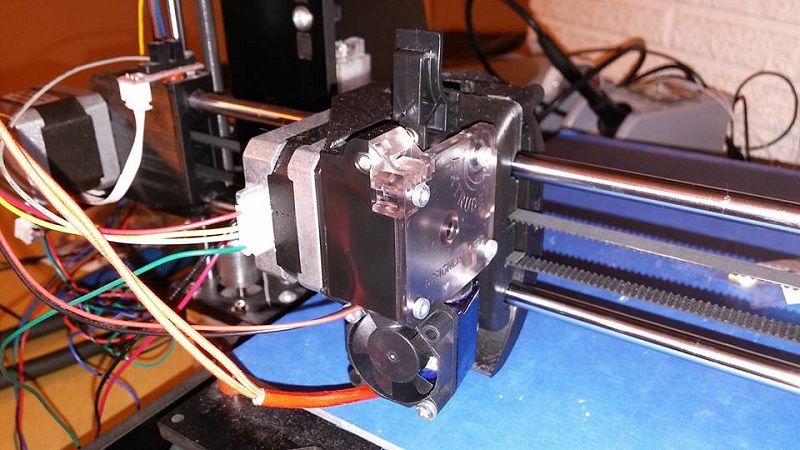

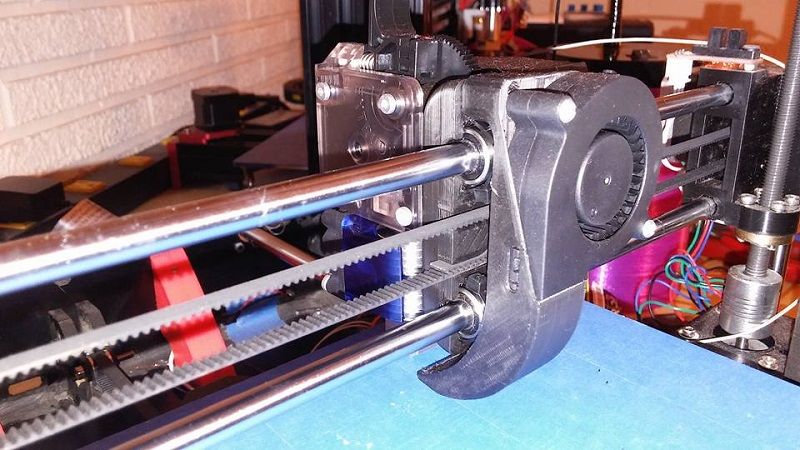

So I decided to go with a lighter weight extruder solution. The titan extruder with a lightweight stepper motor..

The carriage and layer fan are a really neat compact setup. I have to design a mount for the proximity sensor for z height and a flag for the optical x endstop that will attach to this new carriage somehow. But I really like how it mounts the layer fan on the back side..

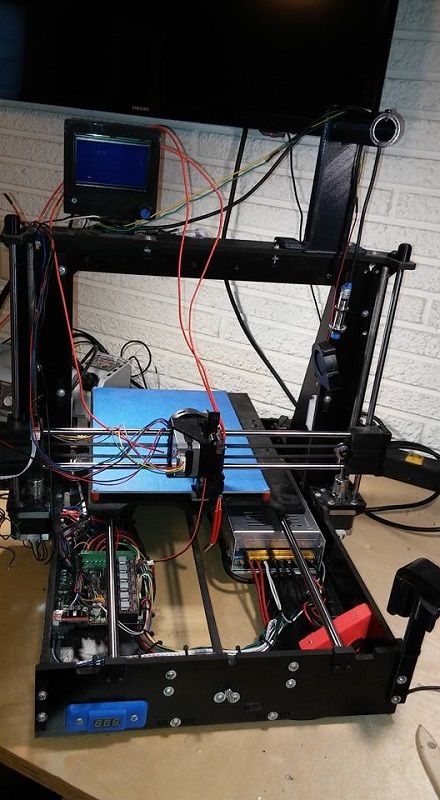

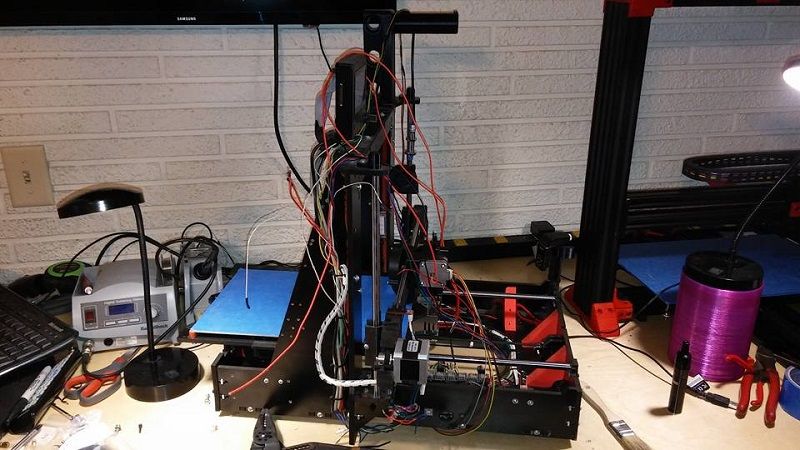

Aside from the power supply upgrade I have decided to also change the stepper motors on x and y axes to 0.9 degree or 400 step/rev motors. The tmc2100 drivers are 1/16 micro stepping and I currently have the 1/32 micro stepping drv8825 stepper drivers. So upgrading the steppers is a good way to keep the resolution up. And at 24v I shouldn't have any issues with skipped steps or holding torque vs. what I was running at 12v. Unfortunately all this means that printalicious is due for some re-wiring..

I don't care how ugly this printer might look to some. This started out as nothing. It was a build from scratch. I started with an ebay unassembled frame and started ordering one piece at a time to make a printer. My other printers I have heavily modified for sure, but this printer I created from nothing. It is not perfect but it is pretty cool. It prints pretty good and it will always be my favorite because it was my creation. And here is the new supply voltage..

There is a voltage adjustment pot on the power supply. I will make that 23.4 say 24.0

Reply With Quote

Reply With Quote

New to 3d printing looking for...

05-20-2024, 12:56 AM in Tips, Tricks and Tech Help