Results 1 to 10 of 26

Thread: looking to build a machine

Threaded View

-

05-06-2017, 09:32 PM #4

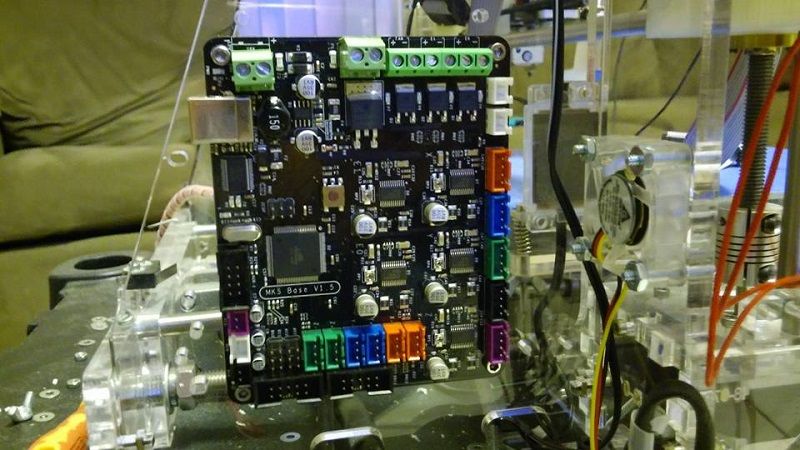

Because of a stated large print area and required large print bed, you should consider a 24v controller and power supply. Most controllers will do 12/24v but this is the first thing you should identify in your hunt. Running 24v will also allow you to use quiet tmc2100 stepper drivers with 1/256 interpolation. These drivers when paired with 400 step/rev. or 0.9 degree stepper motors and a 0.2mm nozzle makes for a high def printer. If you wish to chase down something like this then you also know you want a board with sockets for drivers and not integrated. The mks base boards like this 1.5 I recently swapped into my geeetech i3 have integrated stepper drivers that can not be upgraded or changed. here is what that looks like..

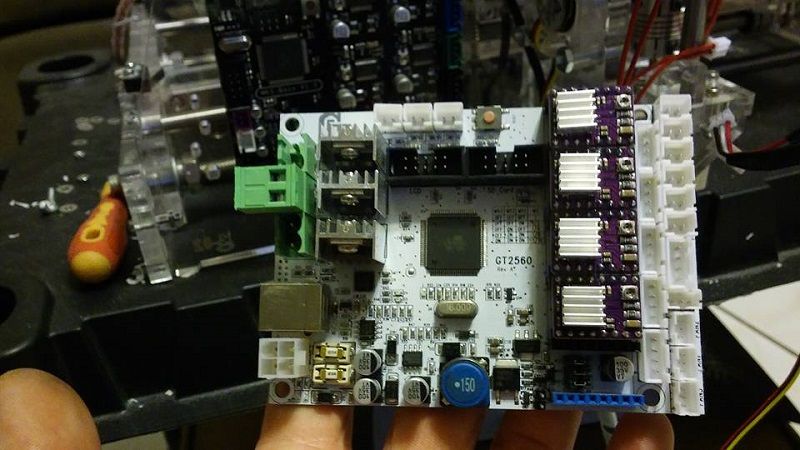

The integrated drivers are a4982 drivers that are 1/16 micro stepping. The board I took out of the geeetech printer was a GT2560. I had swapped from the a4988 drivers that came with it to the better 1/32 micro stepping drv8825 drivers..

Because this swap went from 1/32 micro stepping to 1/16 micro stepping, I had to upgrade the stepper motors themselves to keep the same resolution or number of steps per mm. As far as processing power goes both of these boards are very similar if not exact as with most. The difference becomes features offered by each manufacturer. I have recently started liking the mks boards because they support touchscreens and wifi modules. In my homemade printer I used a megatronics v3 board because it had 6 stepper driver sockets and I was trying to make a 3 in 1 out extruder work..

http://3dprintboard.com/showthread.p...Mixing-Printer

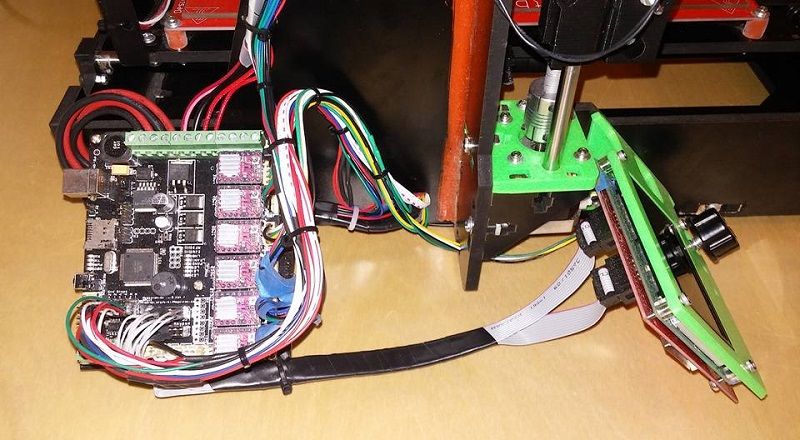

The tevo black widow I am building currently came with a mks gen v1.4 board. The gen boards have stepper driver sockets unlike the more compact base boards. And just like the mks base, The gen boards support touchscreens and wifi modules. But again when it comes to processing power actually driving the 3d printer They all are driven by an Arduino mega / ramps merged board. They all use the same marlin firmware just configured differently. Until you get into the smoothie boards but I think all that is better for the delta's.

All of the above mentioned parts I purchased very affordably off of ebay. So affordable were these parts that trial and error was more fun than pain. Start a build thread and post up pictures of your progress, please.Last edited by AutoWiz; 05-06-2017 at 09:44 PM.

Reply With Quote

Reply With Quote

Printer will print perfect...

Yesterday, 10:44 AM in Tips, Tricks and Tech Help