Results 11 to 20 of 132

Thread: My 3 Color Mixing Printer

-

10-19-2016, 05:24 PM #11

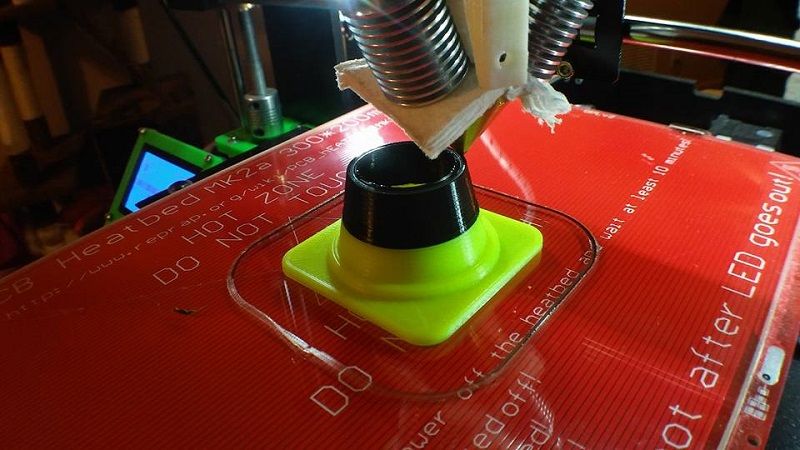

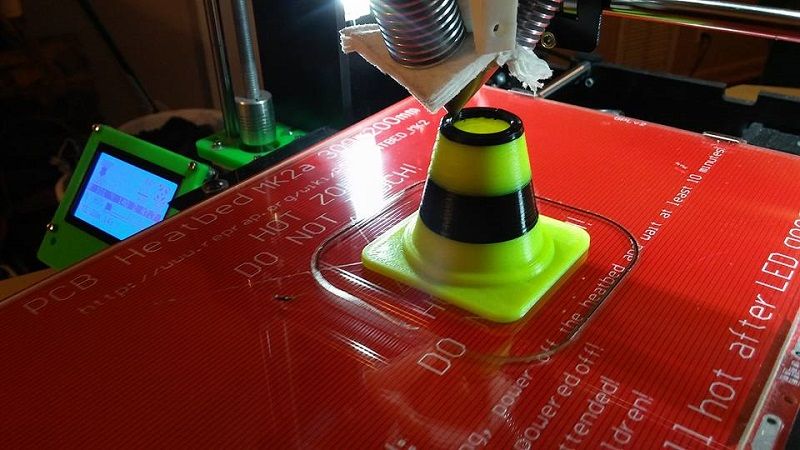

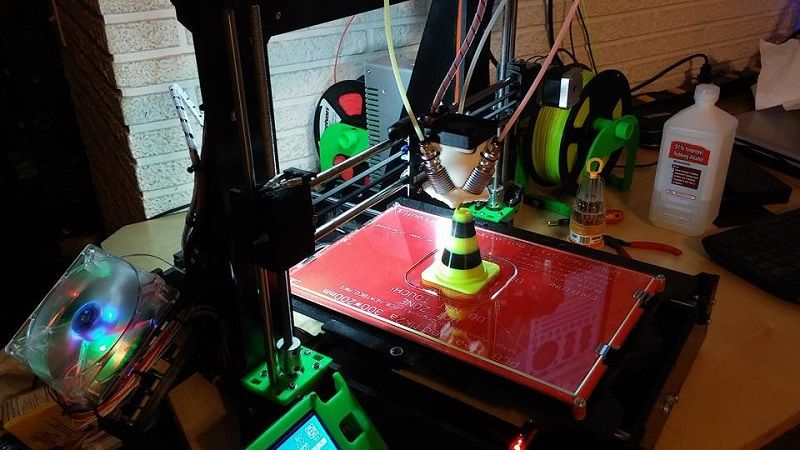

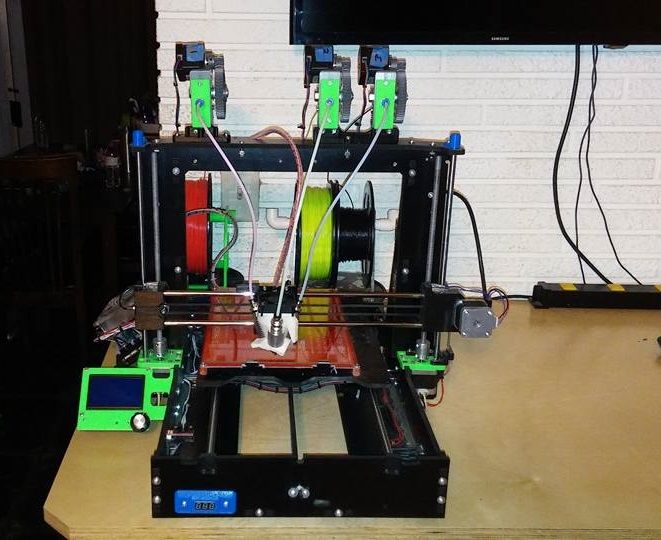

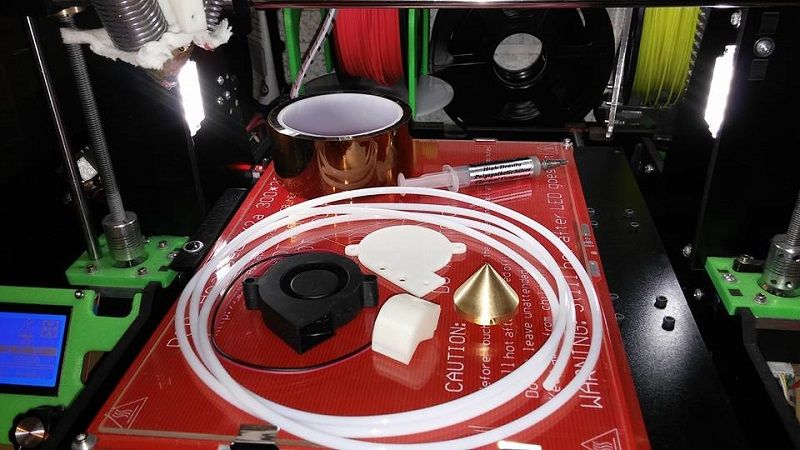

I have finally gotten the positive results I was looking for. It would have been right earlier, But I switched to this clear ptfe tubing and apparently it does not hold up or perform as well at operating temps. And that is my bad. I broke the golden rule of tuning and diagnostics. You make one change at a time and gauge results before proceeding to the next step. I know better. My custom made heatbreaks really did the trick. And here is a cone I made..

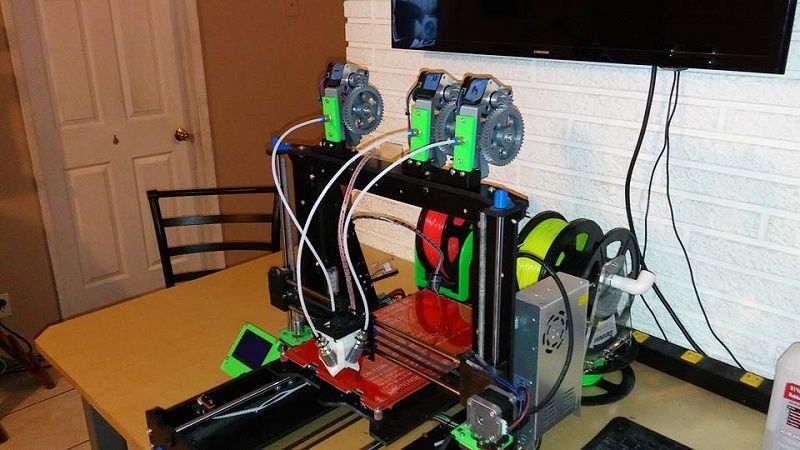

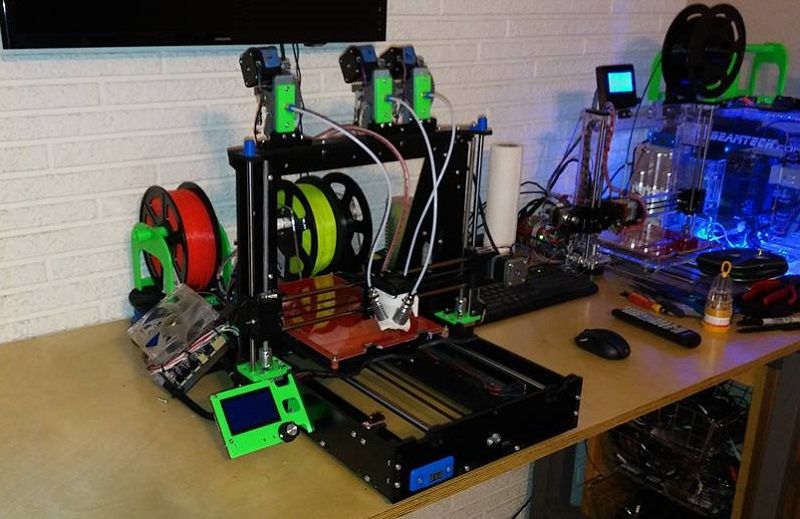

The red filament is still having troubles because there is something wrong with that length of ptfe tubing. the filament is not as easy to push through it as the other 2. So from here my very next step is to fire up the other printer or use this printer and design a new mounting system for the 3 wade extruders in an effort to make the ptfe tubes as short as possible to reduce drag and make it easier for the extruders to move the filament. And I dumped the entire spool of blue filament I had on here. I couldn't find the brand I like in glow in the dark blue and went with this other kind and it was a real bad quality. the filament just snaps and breaks so easy. So I replaced that spool with some black I had left over that was the name I like to use.

-

10-20-2016, 05:43 AM #12

-

10-21-2016, 05:18 PM #13

-

10-21-2016, 06:29 PM #14

Your project is looking good. Nice work.

What kind of tri-color form are you thinking of making?Editor in Chief

Bitsonline

Tips Appreciated But Not Expected

BTC: 16wxHvKd3oU6SVjv6FrenqhkvRmc8t7sPy

DASH: XqyaWxH896j9YeV1M35Gzb5gmRPmPbNDGq

-

10-22-2016, 12:05 PM #15

Well, it isn't perfect, but it can't be put down because it is my very first successful 3 color print..

At the very least this is progress. From here it is a matter of identifying issues and finding solutions one at a time. I will probably re-print this cone a handful of more times making changes in between until it prints decent and at different sizes before moving on to printing anything else. I also still have to learn how to create an image in multiple colors.

-

10-22-2016, 12:22 PM #16

Thank you. I am or was actually hoping to make more than 3 colors. I am new to 3d printing but have some light experience with Arduino boards and am very experienced at fabrication and electrical/electronic systems in the automotive industry. When I saw the mixing extruder, I thought it could be setup to blend filaments and figured if I loaded in the 3 primary colors then with software controlling feedrates I should be able to make every color in the rainbow. That was the whole purpose behind the 3 gear reduction extruders was to give better control over low feedrates because if you want the same amount of filament out of 2 filaments then the extruders have to run at 1/2 speed. I am learning that control does not exist that I have found, or at least yet. But it is a great idea. I am not a programmer and my programming skills are weak at best. So I wont be writing my own software to make purple out of red and blue. I will find it or it wont happen for me.

-

10-22-2016, 05:53 PM #17

-

10-23-2016, 02:22 PM #18

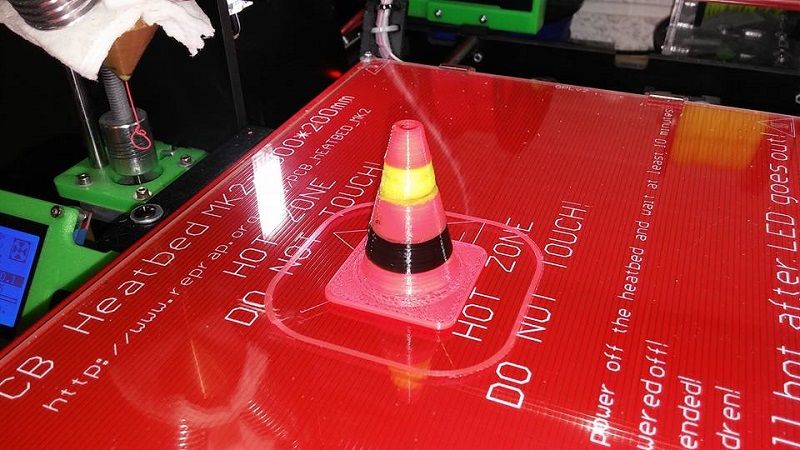

On the subject of temps..

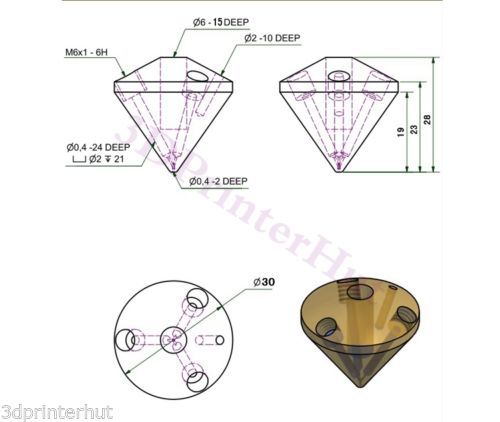

The large cone on the left was printed at 220c. The 2 cones in the middle were printed at 205 and 210. And the cone all the way on the right was printed with the hotend at 215c. The problem with the first print at 220 was the filament completely liquefied and that showed in the print. I have a suspicion as to why I am getting these temp issues where I need a high temp to properly melt the filament and then it is too much. Here is a blueprint of the diamond hotend..

There is a very large surface area exposed to the cool ambient air vs. such a small surface area for the heater. And look how close the bores for the filament are to the outside of the cone. I would bet my life this does not heat up to a uniform temp throughout. So this is my next focal point. I can not find kapton tape locally so the project is on hold for a few days while I await ebay shipping. I plan to carefully and neatly wrap as much of the hotend as possible with 1 or 2 layers of kapton tape leaving only as much of the tip exposed to the air as would be on any other extruder hotend.Last edited by AutoWiz; 10-23-2016 at 02:56 PM.

-

10-26-2016, 10:42 PM #19

I have never been very patient with just about anything in my life. So while I am waiting for the kapton tape to arrive, I used some aluminum foil and tape to make this heat shield and do the same job..

It didn't seem to help in my problem so I moved onto the next step, checking the passages of the mixing hotend for blockage or restrictions. I ordered a special tool set just for this purpose..

And the 2 short bits should explain why I am now waiting on a new mixing hotend. You would not believe how delicate a .35mm or .40mm drill bit can be.

-

11-03-2016, 07:09 PM #20

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help