Results 1 to 10 of 15

-

02-16-2015, 05:00 PM #1

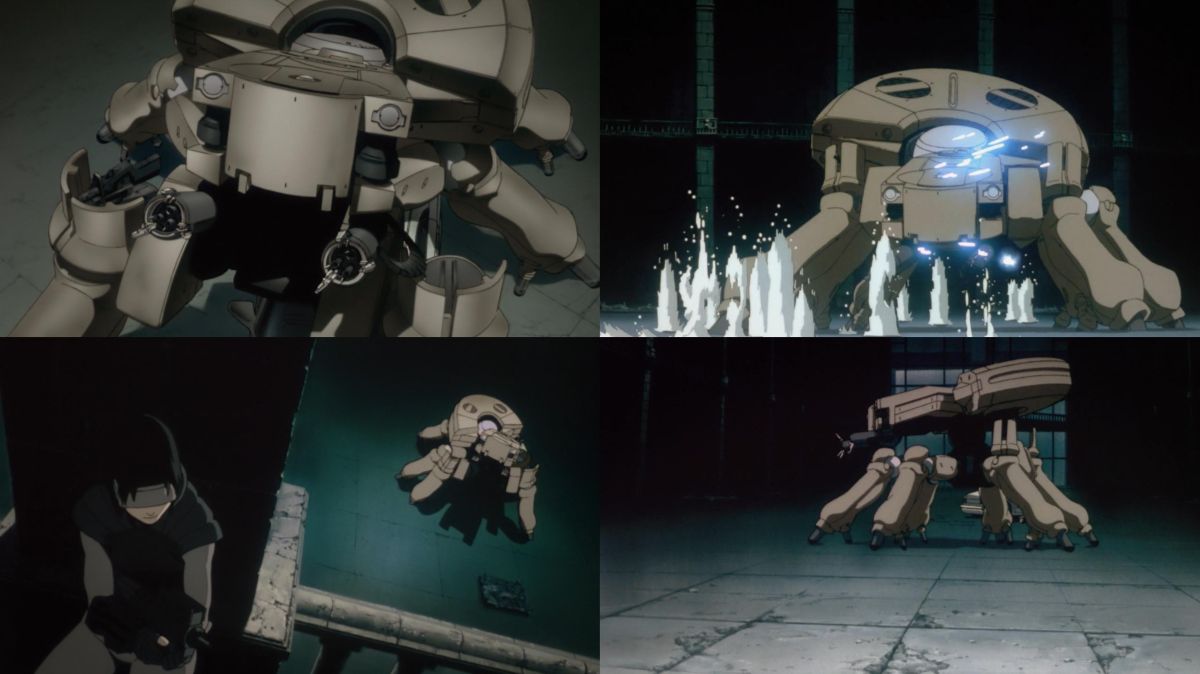

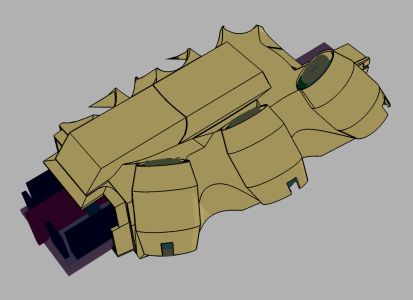

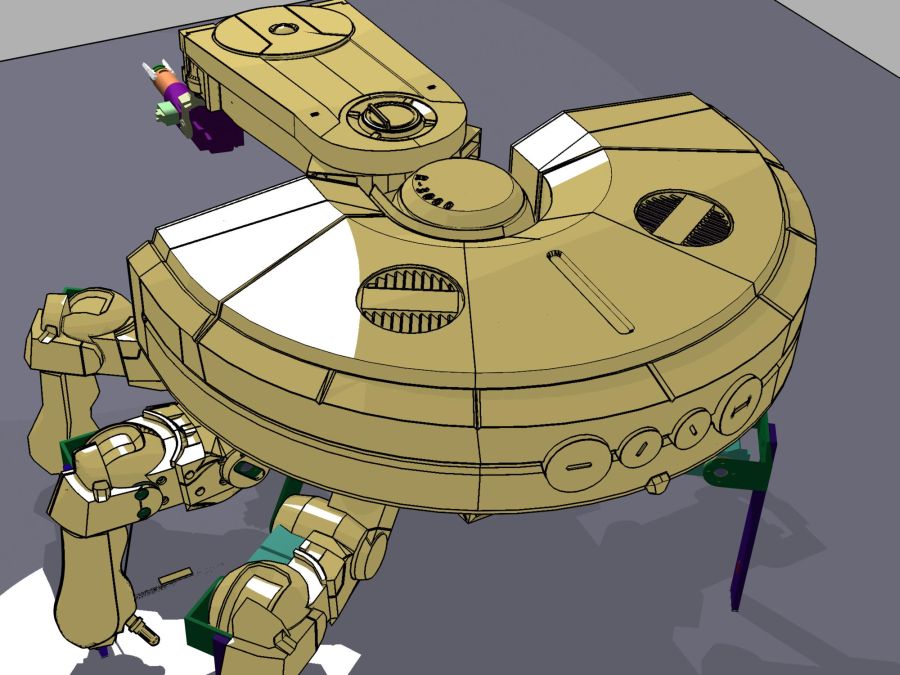

Hexapod robot: T08A2 / R3000 spider lightweight tank (from GITS)

Hexapod robot: T08A2 / R3000 spider lightweight tank (from GITS)

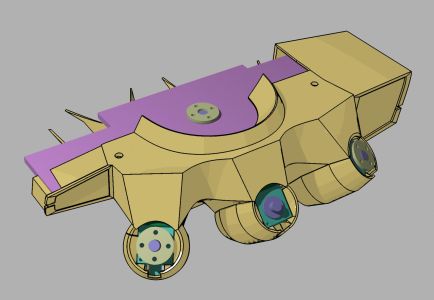

I started working on T08A2 / R3000 spider tank from Ghost In The Shell movie a year ago. For those who haven't seen the movie - I would highly recommend, it's one of the best sci-fi anime movies.

Scale 1:20 (roughly )

)

One of the biggest problems that I had from the start was non existence of blue prints, or actually anything that would be close to that. That's why scale is approximate So for "blueprints" I ended up with a few things:

So for "blueprints" I ended up with a few things:

- Screenshots from the movie

- Smaller resin model from ebay, which isn't proper quality

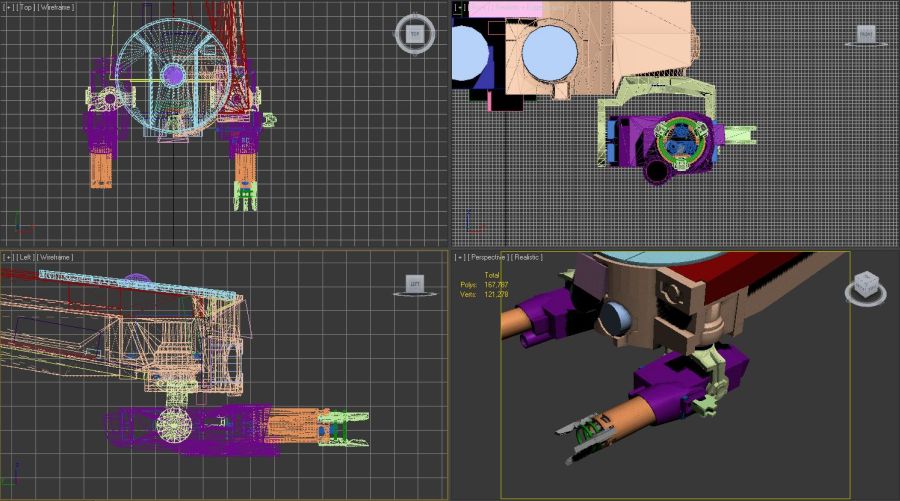

- Someone made a 3D model, which I managed to acquire. It isn't very accurate, I would say it follows movie almost...

So yeah, none of these were precise. Actually, even frames from the movie sometimes contradict itself. To make matters worse I wanted to make a model which could move, so following sizes and strength of mechanical components had to be taken into consideration as well...

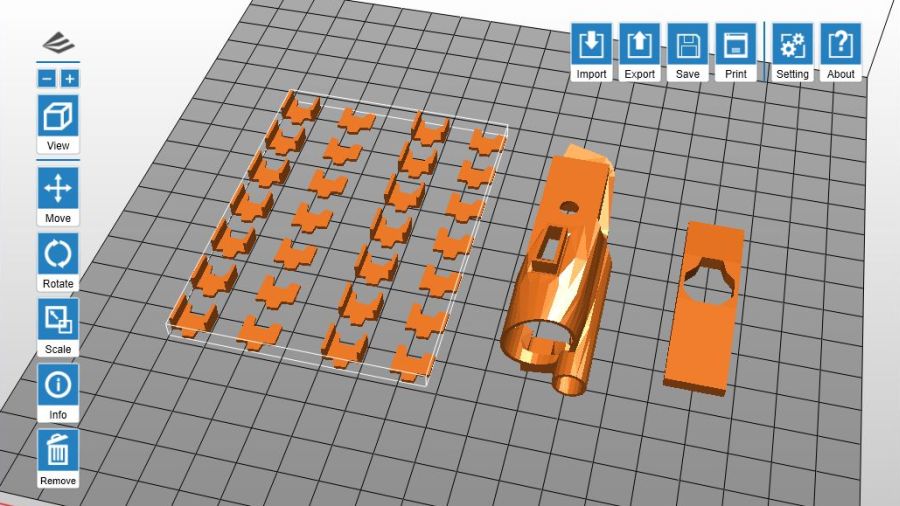

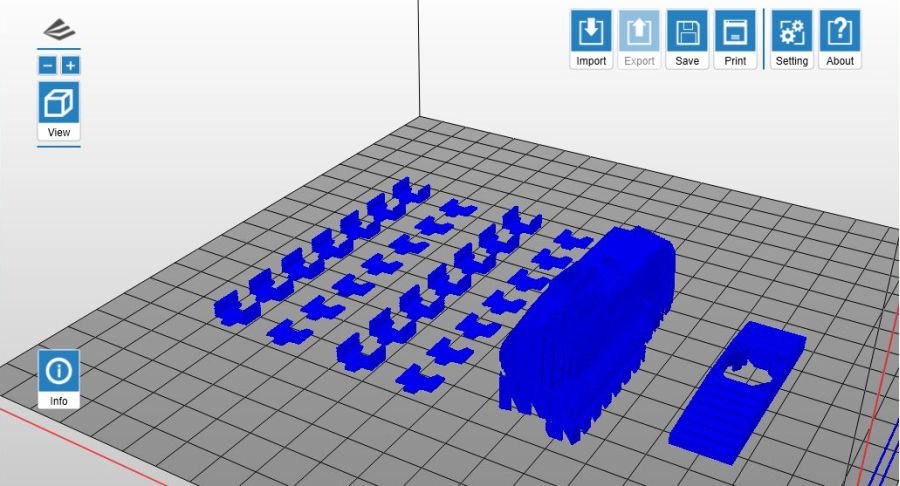

During last year I bought a 3D printer, which came very handy when making these complex shapes

-

02-16-2015, 05:15 PM #2

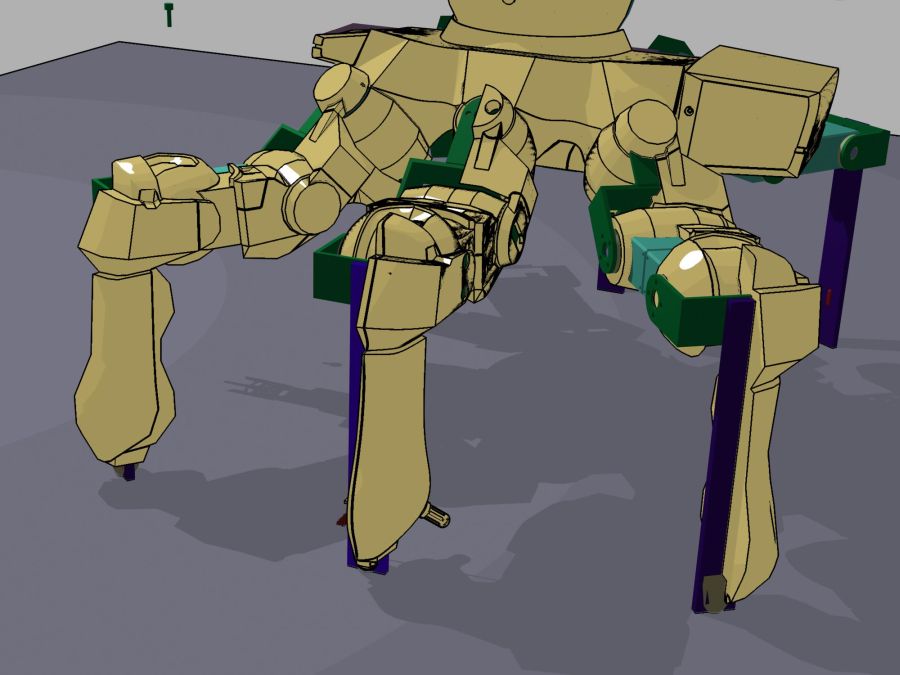

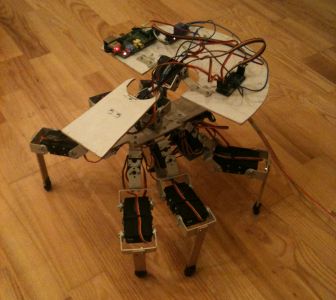

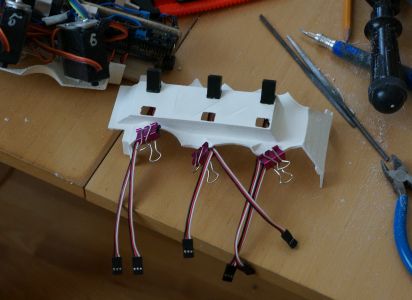

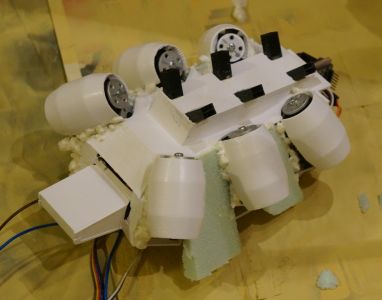

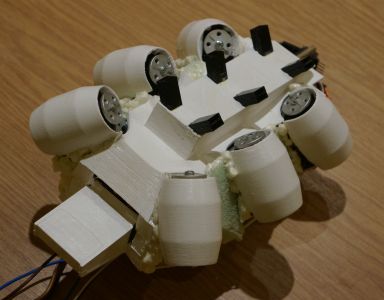

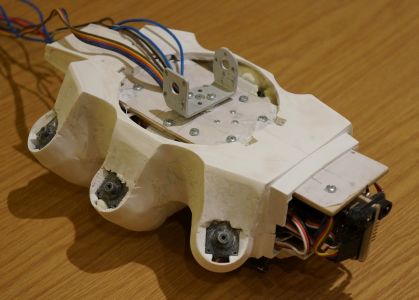

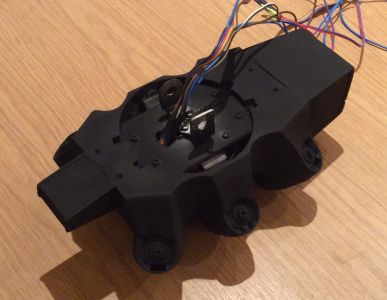

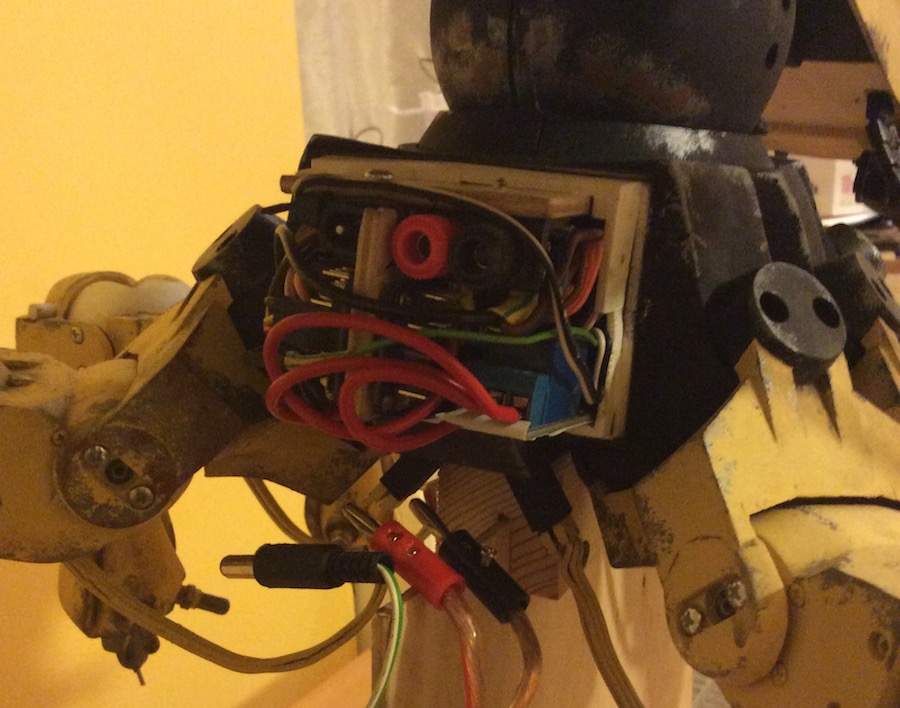

This is almost complete frame (except "arms"/weapons) and close to complete electronics:

Motion is controlled by RaspberryPi. Programming in C++, from scratch. It is controlled with PS3 joystick, but there are plan to have some autonomous functionality.

-

02-16-2015, 05:22 PM #3

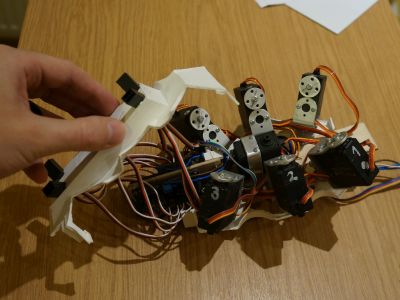

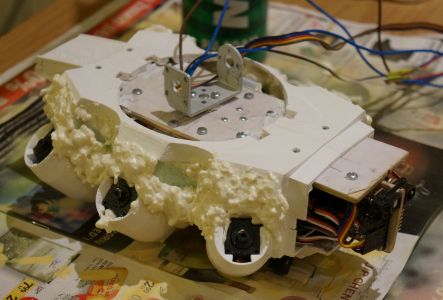

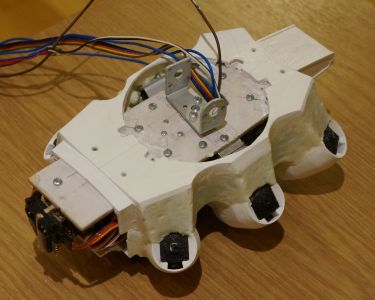

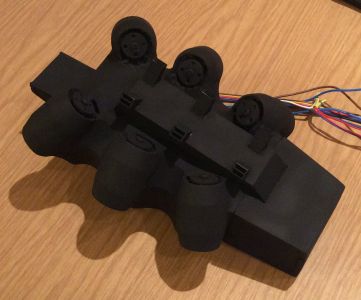

This is one of the better shots from when I got my wiring complete (yay!) including:

- 2x Raspberry Pi mirco computers (1st for motion control, 2nd for face tracking)

- 28x Servos (18 for legs, 4 for body, 6 for weapons)

- 1x Camera (for face tracking)

- 3x Servo drivers

- 2x Lasers (how can you have a robot wittout lazors??!!!

)

) - 1x Distance sensor

- 1x PS3 controller

...and some armor:

I'll follow up with more work-in-progress shots soon...

-

02-24-2015, 08:33 AM #4

A little bit from work progress:

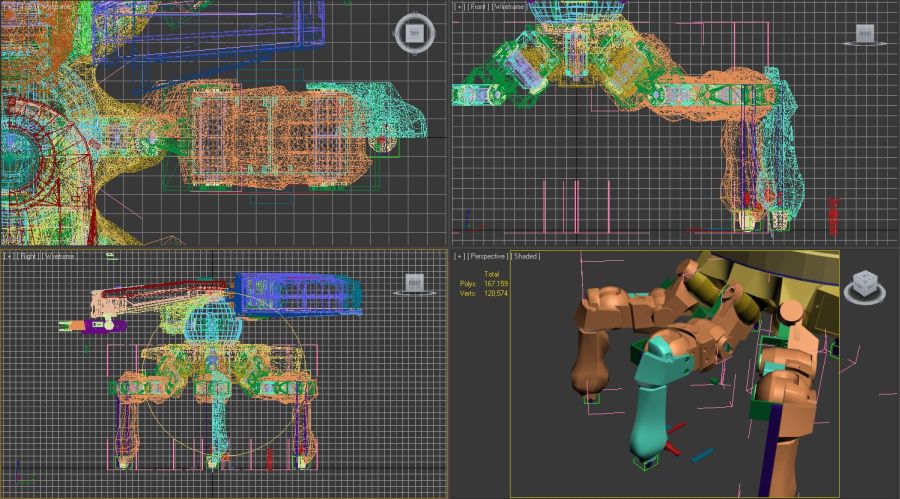

Model in 3dsMax:

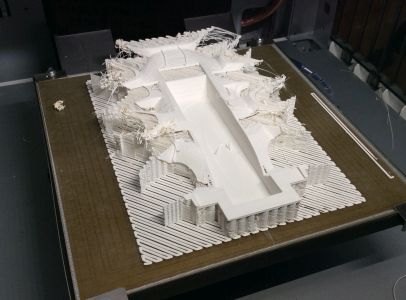

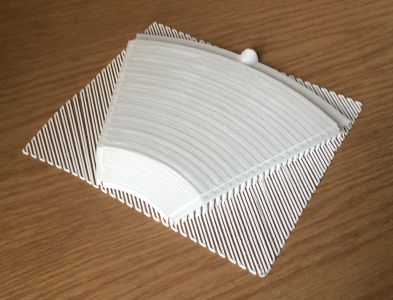

Model in 3D printing program:

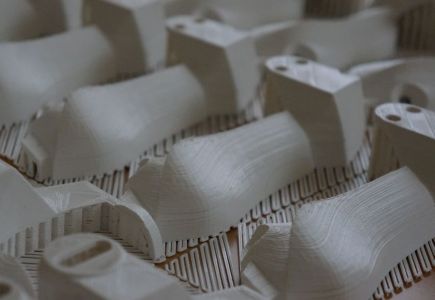

Model in 3D printing program (after slicing):

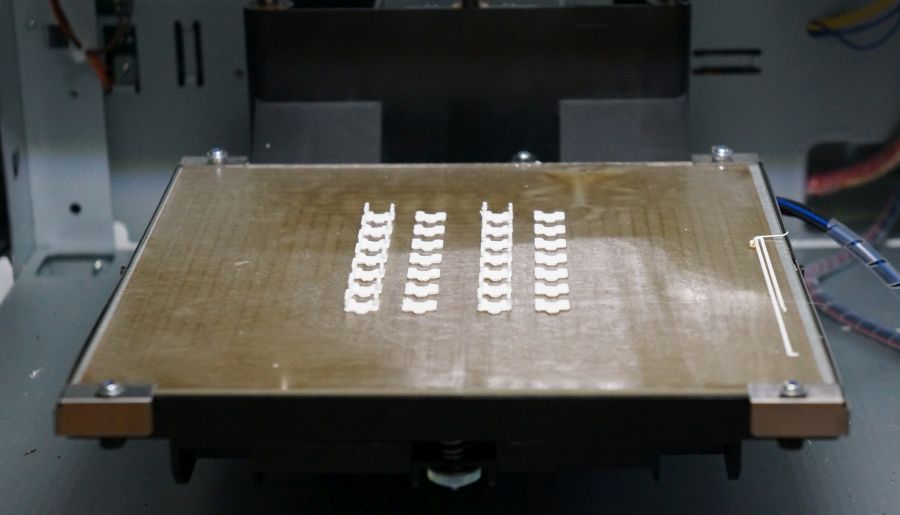

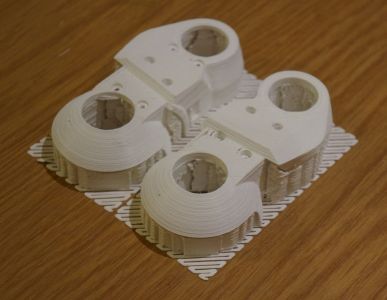

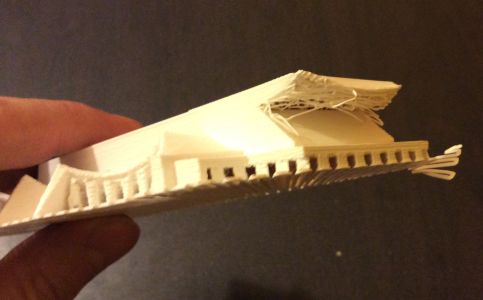

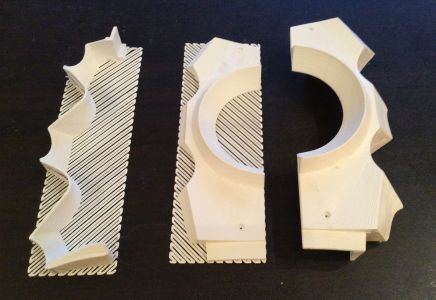

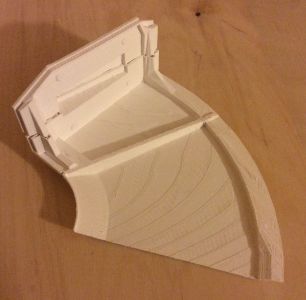

Printed parts:

Here should be some screenshots of work with sanding paper and acetone, because that's a big part of 3D printing, but about that some other time

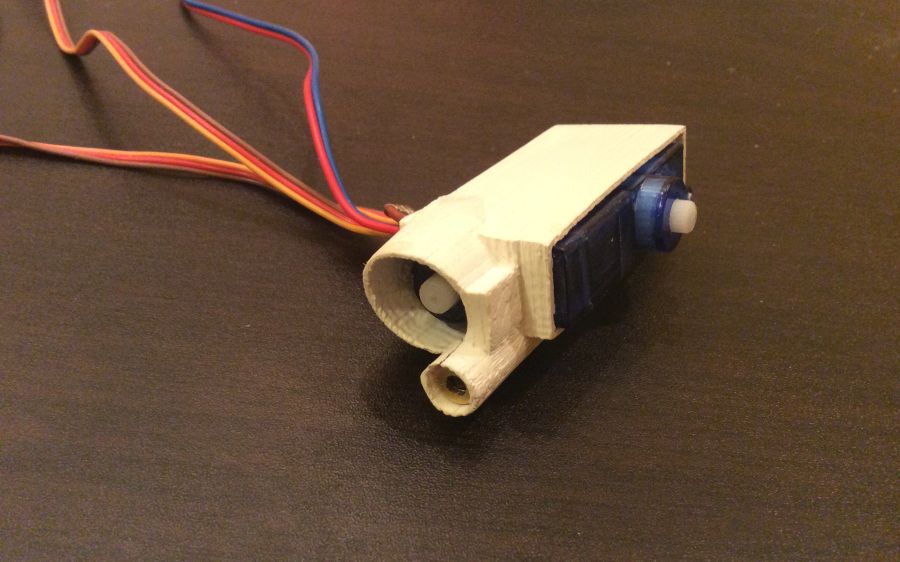

Assembly of electronics (2x servos, 1x laser):

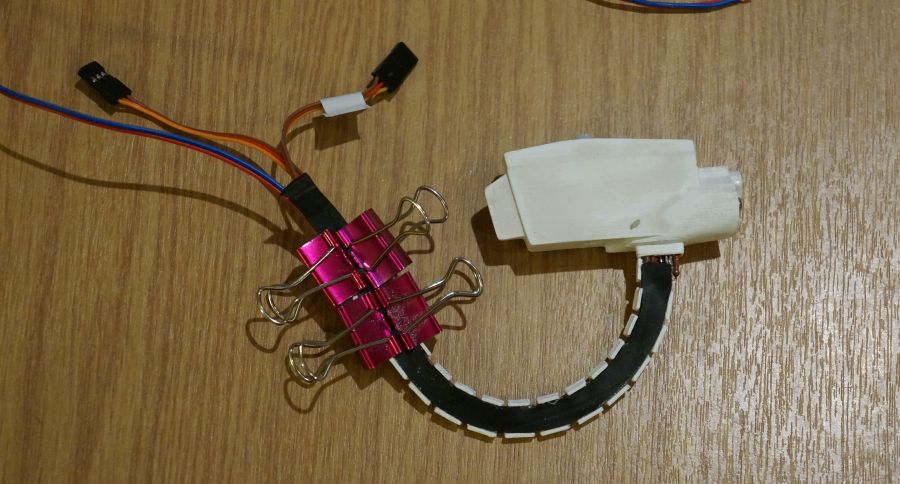

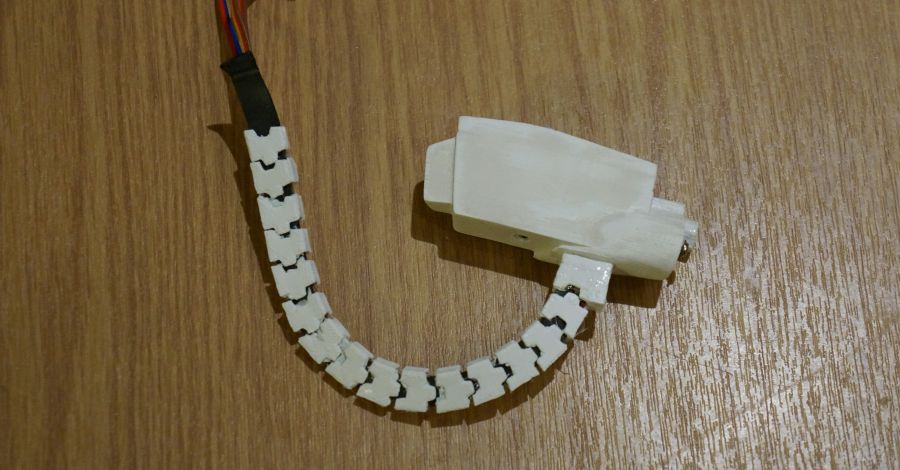

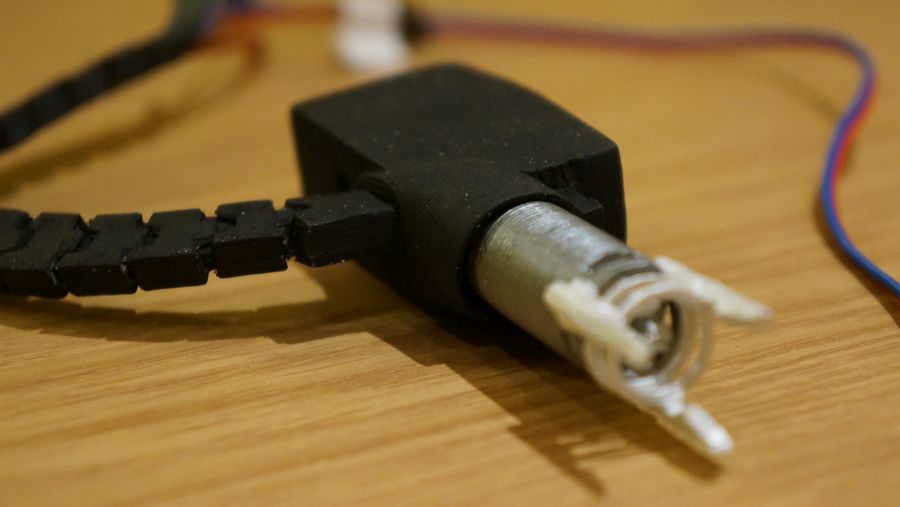

Hiding of cables inside the ammunition belt:

Painting of base color and assembly:

-

02-28-2015, 01:10 PM #5

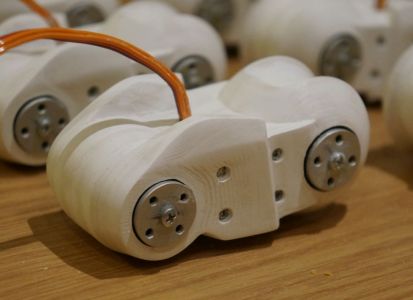

A little bit more of progress on the legs:

3D printing:

Polishing (i.e. reducing visibility of 3D printing slices by sand paper and acetone; acetone also gives strength):

Assembling:

Puttying (is that a word? ) (hiding marks of 3D printing even further):

) (hiding marks of 3D printing even further):

Painting:

Result:

"Suspension" of toes:

I hope to finish main body and the I'll be able to attach the legs. I hope that everything will work once cables are connected (fingers crossed ) Otherwise I'll have to disassemble (read: break) and redo some parts

) Otherwise I'll have to disassemble (read: break) and redo some parts  ) The original plan was to have ability to disassemble, but that was too complicated, so I skipped that part

) The original plan was to have ability to disassemble, but that was too complicated, so I skipped that part

-

03-09-2015, 09:53 AM #6

-

03-18-2015, 04:57 AM #7

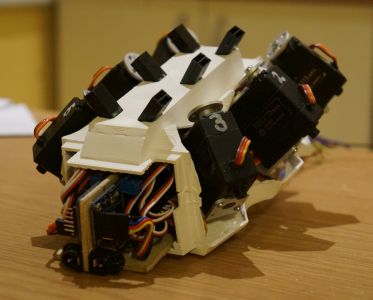

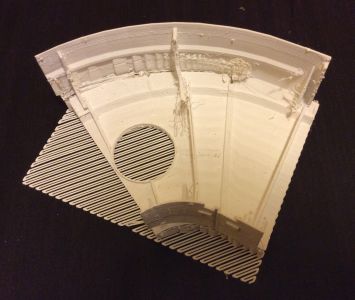

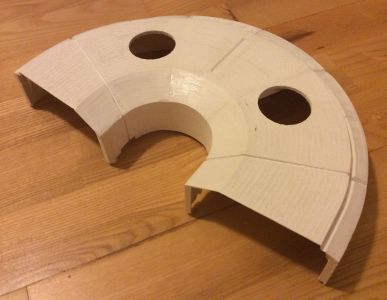

One of the most complicated parts: it's time to cover main-body to which all legs are attached:

The optimistic plan was to print it from a couple of parts:

Problem #1: printer shifts all layers by ~1cm sometime during printing. It still did in a different place when printing flipped part, although the problem was smaller, so I just fixed it by slicing printed part into two and gluing it together in correct place:.

I subdivided the remaining parts into smaller parts before printing in order to avoid same problems during print:

Problem #2: I could not assemble robot using these parts - there was no way to fit sphere in the middle through other parts once everything is assembled. I had to cut it into smaller pieces and attach these parts separately.

Problem #3: first design mistakes: my virtual project had no screws, so when I tried to fit to and bottom part they didn't fit where they belong (see the photo above), so there was a gap of 1cm between them. The main structure of the robot was done by hand without very precise engineering, so gaps between printed parts and servos were uneven. So even if I fixed design problem with the screws there was no I way to fix all gaps. I had to fallback to plan B: use of polystyrene and macroflex To make matters more fun I had to fit wires for 19 servos and plus a bunch of other wires

To make matters more fun I had to fit wires for 19 servos and plus a bunch of other wires

More shaping, macroflex, shaping, making surface stronger using PVA glue, polishing, glue, polishing, putty, polishing, putty, polishing:

Painting and result:

-

03-30-2015, 06:17 PM #8

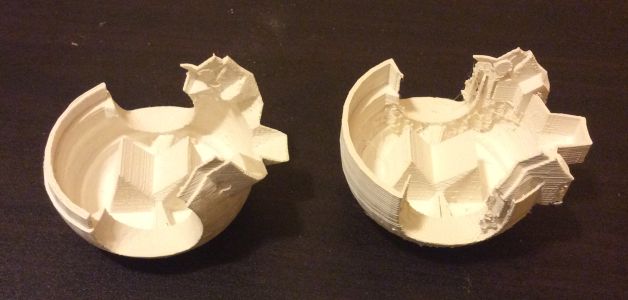

Some photos from older printing:

"Find 10 differences!" or "My printer misunderstood what I actually want to print (correct piece is on the left side)":

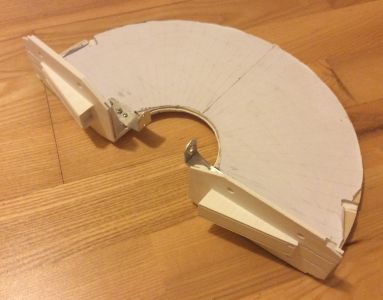

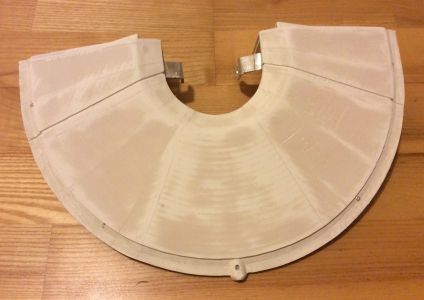

"Tail":

The part is to big to make it as a single print - the max print dimensions 20x20x20cm. It was chopped into 6 individual pieces. The printer was misbehaving again a bit, so 2 out of 6 parts had to be corrected after printing:

Assembled:

I covered the bottom piece with too much acetone, which resulted in bends... I had to cut it, screw to the frame, glue together and use a lot of putty afterwards

I had to cut it, screw to the frame, glue together and use a lot of putty afterwards  There is still small gap between the top and bottom, so I added a screw to tighten them together after closing. The top and bottom are not glued together, since main electronics sits there and I need to service it occasionally or attach screen and keyboard when coding for it.

There is still small gap between the top and bottom, so I added a screw to tighten them together after closing. The top and bottom are not glued together, since main electronics sits there and I need to service it occasionally or attach screen and keyboard when coding for it.

Result:

-

04-13-2015, 07:14 AM #9

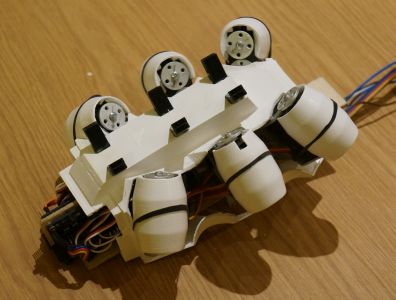

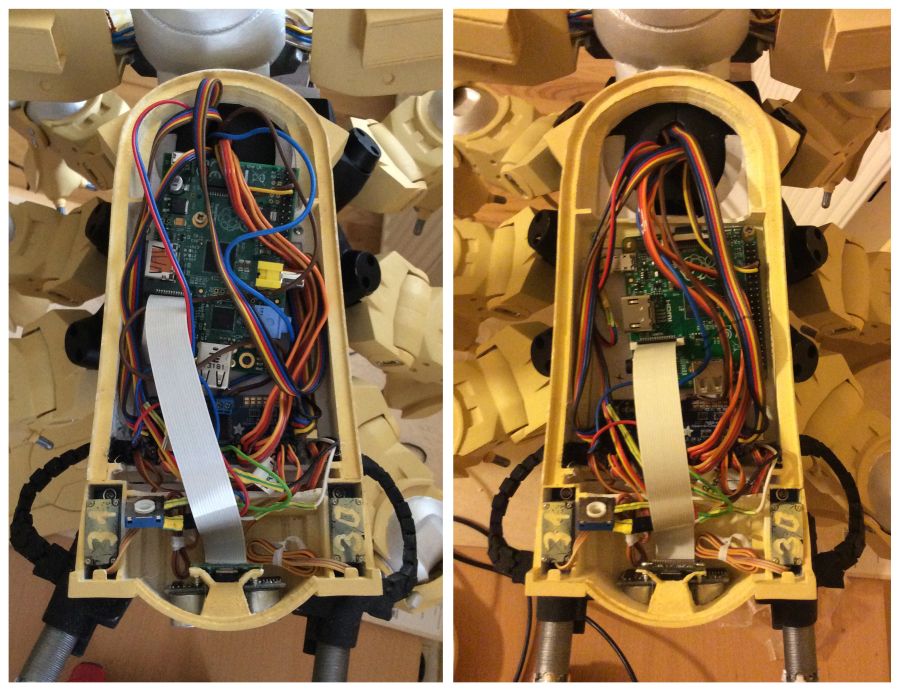

I found out that the old RaspberryPi (model B) is getting in a way of cables after assembling all printed parts, so I replaced it by newer model A+. Everything fits much better now:

This is how it looked before the painting of details:

-

04-25-2015, 05:27 AM #10

I finally found time to fix electronics.

Main change: I switched to power source with higher voltage (from 5V to 7.5V) - this gives more strength to the legs. One of the main problems was that it was having hard time standing on the legs after putting so much plastic on it. The robot weights ~5kg now. New and shiny power source:

Of course RaspberryPi still needs 5V, so I had to put voltage stabiliser. That leads to some energy loses, but who cares when you're not planning to use batteries and you have 26A )

)

I also had to switch to shorter and thicker power cables for servos. And better plugs for those cables too. I'm glad I didn't have to pull any new cables through internals of the robot - it would be very hard to do at this point Although I still had to put a relay in the back and some thick cables. It doesn't look nice (when it's open), but it works!

Although I still had to put a relay in the back and some thick cables. It doesn't look nice (when it's open), but it works!

I found out that servos in arms take 6V max, so I had to put another voltage stabiliser Any change is never as easy as it seems at first sight

Any change is never as easy as it seems at first sight

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help