Results 41 to 50 of 173

Thread: My First CoreXY

-

11-24-2020, 06:57 AM #41

I see why you need a glass bed. I was looking at things you can actually get filament off the other day - and you can get pei filament !

So - yup, that ain't going to come off a pei coated bed :-)

The beast is looking well sharp.

I guess with the black and yellow colour scheme you should call it the bumble bee or the Wasp.

Given that it's meant for car parts - got to be: Bumble Bee !

wow 50watt heater cartridge. I mean I have no idea what wattage a standard cartridge is - but 50 watts does seem like a lot !

My led floodlight that lights up the entire garden is only 30 watts :-)

-

11-27-2020, 04:53 AM #42

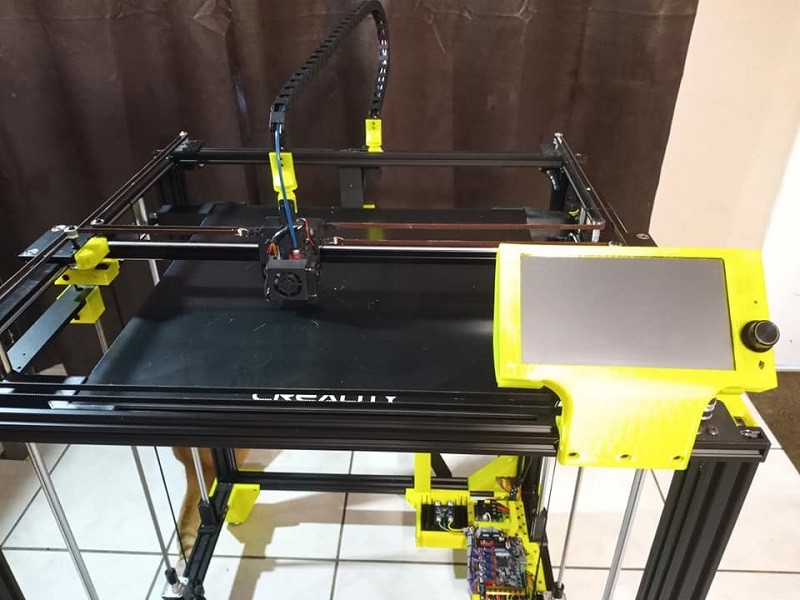

I am almost done. The printer is wired. I still have to program it. There is one last thing I am addressing on this printer before I begin to setup Marlin for it. These printers seem to have a problem with the bed dropping after the power gets shut off creating a need to re level the bed every time the power gets cycled. One can only imagine that any type of a resume after power failure feature would be lost in this type of a scenario. This problem is created by a combination of the weight of the Z axis along with the aggressive thread pitch on the lead screws. The fine pitch lead screws hold their position better but will slow down how fast Z can move. There are also these elaborate belt drive setups i have seen some even including a third threaded rod for the rear of the bed. But my approach is a little different. I have designed a mount for the top of each leadscrew to hold a few idler pulleys and hold one out a little ways from the lead screw. I am using lengths of the gt2 belts that came with the printer and i have some 3lb fishing weights coming from ebay. I am making a counterbalance to negate 6lbs worth of the bed's weight in hopes that the bed will stay wherever it is without power holding the stepper motors still. I will post up pictures as soon as I have weights. Ebay needs to hurry up.

-

12-02-2020, 10:17 AM #43

ingenious.

Although how fast does the bed NEED to move ?

The shallower threads would surely have been the simpler option ?

-

12-06-2020, 09:49 PM #44

Well the 8mmx1.25 threaded rods seem to limit the Z movement to 5 or so mm/s And when we are talking about a 600mm build height them fine threaded rods can bring about long homing times after big prints. This will let me keep the correct threaded rod size to match the build envelope I am working with. Also to take away from the lifting weight means I will be able to home faster just because the motors will see less load. Up to half the load in fact if I perfectly balance the bed and weights. The 3lb weights are not enough so I ordered 4lb weights. One on each side. I am pretty sure my Z axis weighs 10lbs or more. So it is a lot of load for them steppers to lift that kind of weight. And sure they are big motors and they can do it but that is just a bunch more current flowing out of the stepper drivers heating them up good and proper. With the 3lb weights installed here is my printer with the bed up..

Mid travel..

And all the way down..

For those interested the rig next to the printer can be seen in better detail here: My New Machine | General Conversation (superchargerforums.com)Last edited by AutoWiz; 12-06-2020 at 10:16 PM.

-

12-07-2020, 10:19 PM #45

-

12-24-2020, 12:33 PM #46Student

- Join Date

- Dec 2020

- Location

- N colorado

- Posts

- 19

Your skills are amazing. I just read this thread and your black widow thread. Wow. I am looking at purchasing my first 3D printer. I am not afraid of building and customizing. I build drones and have to program them. I may need to get 2. One to build and one to print the parts I need. I guess I could build one and print all the parts, Hohenzollern disassemble and rebuild. I guess that is what you do, although you didn’t even build this one before you started modding it.

-

12-25-2020, 08:34 AM #47

Oh wow. Hey Thank You, buddy. Really. I was into making stuff and things long before 3d printing came about. For me in the old days, in the before time I had to use radio shack project boxes, a soldering iron and hot glue to create for my electronics projects. I made some incredible things in those days. And all of it can only be remembered as art. When I got a hold of the ability to rapid prototype like this with such precision, oh man. I had absolutely no experience going in with any type of 3d or cad design. It was all new to me, and I started with a digital slide caliper/micrometer and a protractor. I am still only good with the very basics of the 3d design software and I really only use autodesk 123d design which everybody shames me for today. I had to find youtube tutorials for everything I did. This right here is the youtube video that taught me how to create in a 3d space: Autodesk 123D Tutorial - YouTube . Because I was always good with my hands and electronics I started with an ebay 3d printer that required a lot of assembly and by the time it was together I knew a lot about the machine I was using. There were a lot of times in the beginning for me where I had a laptop next to my pc with a tutorial on one while I was going through the motions in the slicer or with arduino(now atom). And that was back in 2016/2017. Today there is just so much more support out there as this tech tries to mature. If you are already good with electronics and working with your hands and it sounds like you are then you should have a lot of fun here. Godspeed and whatever you do, don't forget to share with the group. And MERRY CHRISTMAS !!!

-

12-25-2020, 04:09 PM #48

You should definitely get 2 if you really want to have fun with the modding. Because it will empower you to have a printer down and still be able to 3d print so if parts don't fit or other ideas get tossed in the mix after the rework starts you still have a path to producing parts instead of having to work with what you got or put it all back the way it was to print new parts. I have 4 printers today and am commonly fleshing out upgrades on multiple printers at the same time. But I always maintain at least one robot ready to run no matter what. Honestly if I were starting over today and I were to go for just 2 I think I might go for the Prusa mini. It is easy to assemble. fast to get up and printing. Prints in incredible quality. And is the perfect size for making most parts at 180*180*180 build envelope. Then I would hunt down the largest format CoreXY I could find. Which BTW is the TronXY X5SA 500. That would be a winning combination I think. All your tinkering will be worthwhile as it will be for large format capability. And you will always have something reliable to fall back on so you will never loose this awesome and powerful newfound ability.

-

03-27-2021, 02:34 PM #49

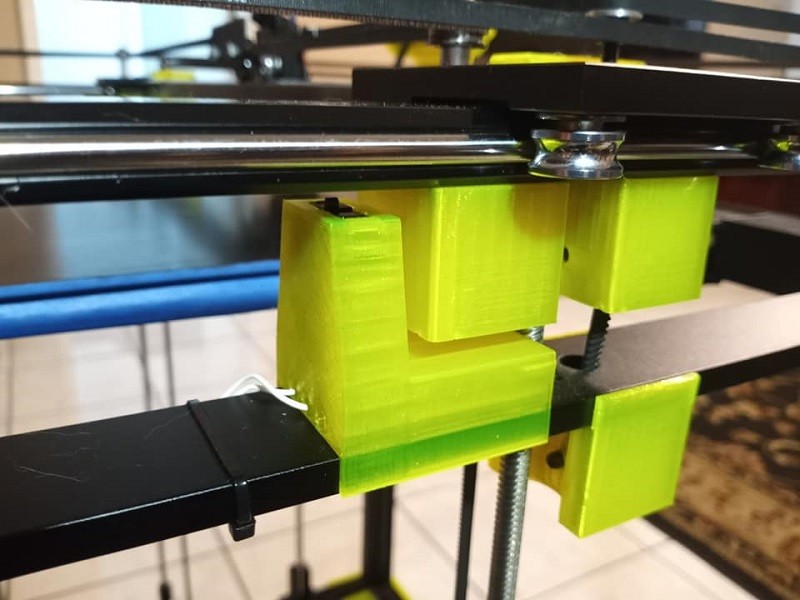

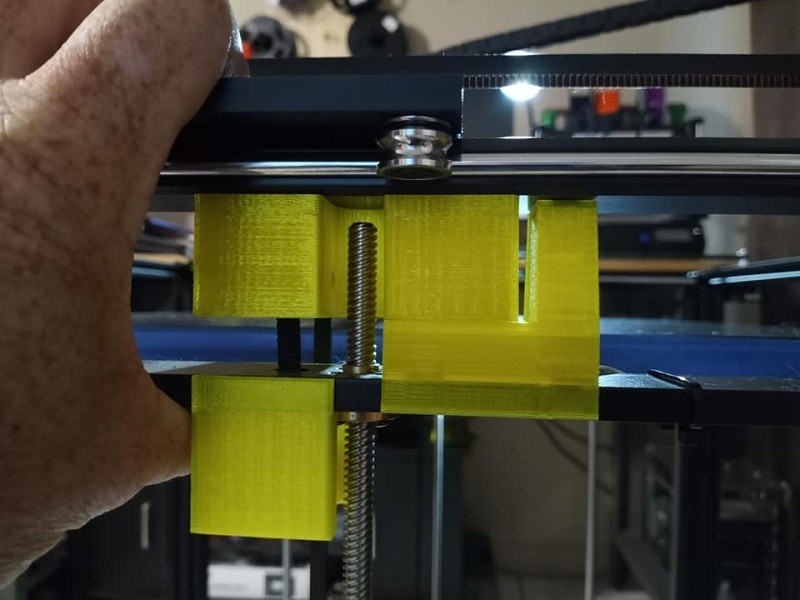

One thing I have noticed in the groups is all the TronXY build surfaces with the deep gouges through them. Apparently there is a thing about the stock firmware driving the plate into the nozzle and some convert the oem board to run on Marlin and others switch to BLTouch or other different sensor. Some use separate drivers for the Z motors and I would like to show off my better way. For Z homing on my 500 Pro I am using 2 of these old school dirt cheap in every possible way early i3 style endstop switches..

These switches get wired in series back to the Z min endstop signal and gnd pins. This way the circuit is completed only when both switches are closed together. I remove the metal tab from the microswitches for better repeatability and accuracy..

One on each side..

This design creates a hard stop right as the switch is closed so the carriage will not flex upwards and the motor will immediately begin to skip steps after the switch is triggered. This height of these stops is absolutely critical and puts the glass bed in a place where it can be adjusted to level and the right height with just the springs underneath it. As Z homes one side will bottom out and skip steps until both switches close and the bed is level..

And now setup like this we can home and print without probing the bed in 12 places and wasting 10 minutes of our lives at the start of each and every print. And as an added bonus it is now physically impossible for the nozzle and bed to do the touchy touchy thing. Which is good because I really like this Creality branded Ultrabase..

-

03-31-2021, 06:02 AM #50

physical endstops - yep :-)

So all we need now are the closed loop steppers and a heated enclosure :-)

So what's the thing you were watercooling ?

A gaming pc presumably.

You still on intel ?

Reply With Quote

Reply With Quote

Ender 3v2 poor printing quality

10-28-2024, 09:08 AM in Tips, Tricks and Tech Help