Results 41 to 50 of 54

Thread: simplify3d

Hybrid View

-

01-28-2015, 03:45 PM #1

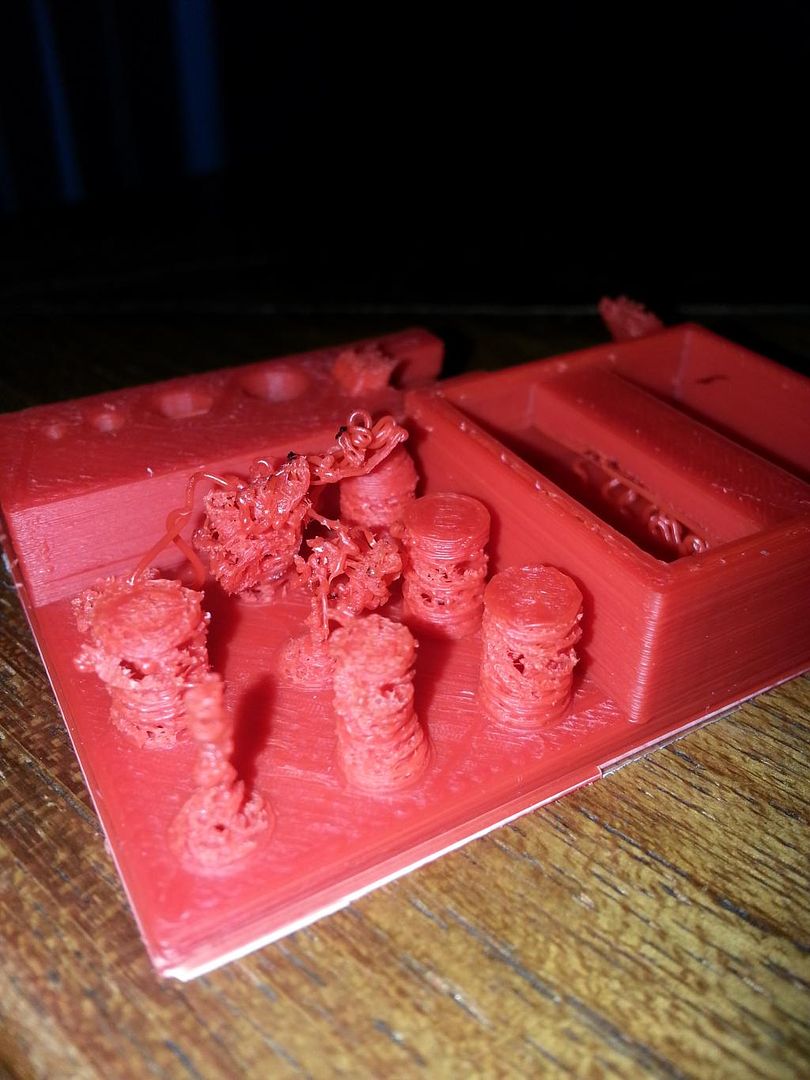

A few more test print from yesterdays snow day..

Cura with the same base settings as the S3D at .1 layer height

-

01-28-2015, 04:12 PM #2

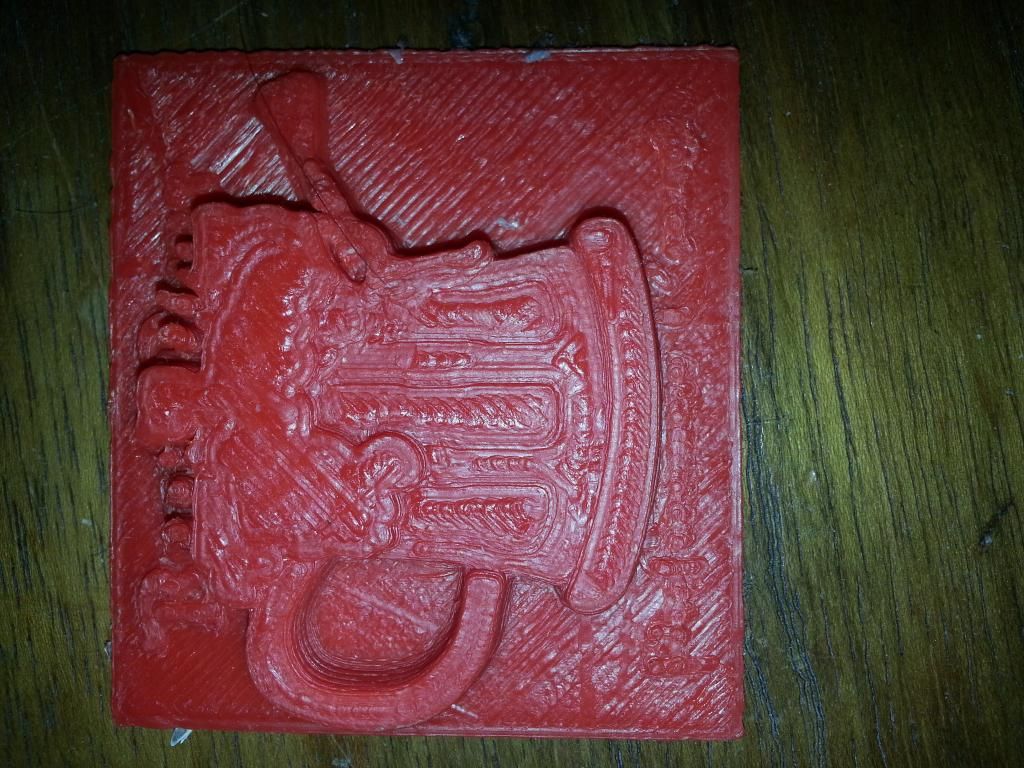

Another cute feature is the ability to import a photo or any graphic and 3D slice it.

-

02-04-2015, 10:07 AM #3Engineer

- Join Date

- Dec 2014

- Location

- Canada

- Posts

- 498

An update has been released with some interesting improvements

http://www.simplify3d.com/get-your-calipers/

-

02-09-2015, 09:32 PM #4

Thanks for the insight pichuete.

Where are you changing the Z Movement Speed? The S3D "Other" tab? The MakerFarm value for Z in DEFAULT_MAX_FEEDRATE is 2 mm/sec, so anything S3D asks for over that will be limited to 2 mm/sec instead. My testing led me to believe that's also about the top end for the combination we have of NEMA17s turning M5 rods to lift a fairly heavy x-carriage.

-

02-09-2015, 10:42 PM #5Technician

- Join Date

- Nov 2014

- Posts

- 58

yes is was changing it on S3d trying to see if it make a difference with some Gaps/Layer Shift between layers im getting . but i didn't know the fact that the firmwares limit the movement....

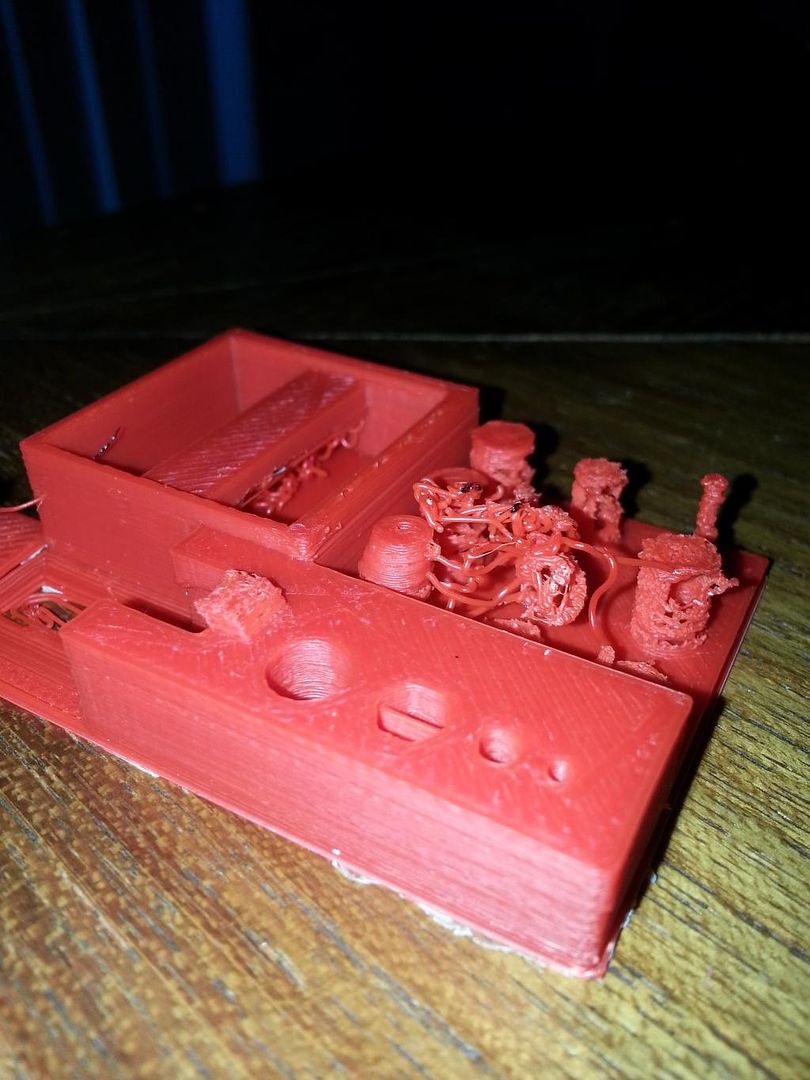

also i was wondering what average speed works for you . i have found that the default setting are Extremely Fast compromising the print quality . i tamed down to this and still found to be fast for prints like this one i just did .

ABS 0.3mm 230C 15% infill

-

02-08-2015, 03:00 PM #6Technician

- Join Date

- Nov 2014

- Posts

- 58

hi guys so after almost a month battling with some mechanical and firmware issues, now im starting to get "Decent" prints . but now im struggling to get retraction to work properly . im not getting a lot of oozing over the print but i have notice this gaps / Blobs every layer change or when the nozzle move to another spot. Im using the Stock Extruder (gregs)

i was wondering what setting for retraction is working for you and how can i minimize this .

-

02-08-2015, 05:19 PM #7Engineer

- Join Date

- Oct 2013

- Location

- new jersey

- Posts

- 752

you can probably increase your retraction speed. that generally want to be as snappy as you can make it. turn on coasting. start with 1mm then slowly go up from there. this stops extruding the plastic "x" distance before the end of a line. this helps reduce pressure. also turn the wipe feature on to the default 5mm.

-

02-08-2015, 11:22 PM #8Engineer

- Join Date

- Oct 2013

- Location

- new jersey

- Posts

- 752

Well wipe drags the nozzle back over the already extruded filament for a certain distance. It can just make the filament look odd. There really shouldnt be anything on the surface you can feel. If the start points are randomized you wont get that. Other than random starts you really cant get rid of that

-

02-09-2015, 04:35 PM #9Engineer

- Join Date

- Oct 2013

- Location

- new jersey

- Posts

- 752

the wipe happens at the start and end of a line. usually s3d starts and ends at a corner somewhere. are your perimeters starting mid line like that? 10mm is a bit overkill. 3-5 usually does it. i dont get anything that looks like that. unless you have a really oozy nozzle and dont have retract or coast on or anything like that.

-

02-09-2015, 05:14 PM #10

OK, good to know you don't see them. As I mentioned, I haven't went back to experiment other than increasing the wipe distance from 5mm to 10mm. The results were the same - I just don't have a photo of the print with wipe set to 5mm.

Retraction and coast both on. Retraction speed at 15mm/sec, about the best I can do reliably. Retraction length would have been 1.6 or 1.8mm. Coast at end for 1.6mm.

There are notches and holes in the test print that effectively carves most of the layers into four segments - one for each corner. As you said, S3D starts a line in a corner. I'm printing external perimeters first. So, the print starts in a corner and forms the outer perimeter shape of the segment. When the nozzle gets back to the starting corner, the nozzle wipes the 5 or 10mm over the starting part of the segment, stops, and moves back to the corner to start on the inner perimeter. The artifacts are occurring at the point where the nozzle stops at the end of the wipe move to move back to the starting corner.

Reply With Quote

Reply With Quote

Please explain to me how to...

Today, 11:51 AM in 3D Printer Parts, Filament & Materials