Results 101 to 110 of 189

Thread: Show your MODS

Hybrid View

-

11-08-2014, 02:00 PM #1Engineer

- Join Date

- Jul 2014

- Location

- Eastern Colorado

- Posts

- 536

Do an advanced search for "hexagon" and seller "clough42".

-

11-21-2014, 01:39 PM #2

-

11-21-2014, 02:37 PM #3

I can answer that just a bit. I'm working with him to refine and perfect it. Actually, I'm getting my copy of it set up today and starting some tests. It's looking fantastic but not ready for prime time just yet, but pretty close. But, that's his call.

I'm just being a Beta tester I guess you could say. I've built it and am comparing notes with him to see where we match and where I'm different. It's coming along though. I'll let James weigh in...I've said enough.Bambu P1S/AMS

NVision4D http://nvision4d.com

-

11-21-2014, 03:19 PM #4

I'll start another thread later today. I'll make early bits available on GitHub, but I'm not ready to put this on Thingiverse just yet.

-

11-21-2014, 07:29 PM #5Engineer

- Join Date

- Jul 2014

- Location

- Eastern Colorado

- Posts

- 536

I've added a RasPi and a relay board to my printer, which now makes it (almost) completely controllable remotely over the internet. The only thing I cannot yet do remotely is remove the finished part from the bed to start a new print.

I can turn the printer on and off, control the fans and lights, upload gcode and start prints.

-

11-26-2014, 08:56 PM #6

Introducing the Itty Bitty Double Extruder

At long last, I'm releasing the Itty Bitty Double Extruder: http://www.thingiverse.com/thing:566329

LeftFront.jpgExplode2.jpg2014-11-24 21.46.23.jpg2014-11-25 00.28.55.jpg

Based on MakerFarm hobbed bolts, Hexagon hot ends and NEMA 14 motors, it's super-compact, with the hot ends on 20mm centers and the whole package narrower and lighter than the stock single extruder. I've included everything you need to mount the extruder on a MakerFarm i3v printer, with hot end cooling, print cooling and a servo Z probe all integrated into the system.

Many thanks to RobH2 for countless hours of prototype testing and feedback.

If there's interest, I can start another thread for discussion.

-

11-28-2014, 09:41 AM #7

I'm very interested in your Itty "Bitty Double Extruder, I have most of your mods installed on my i3v and this would be the next step in the evolution of my machine. if you decide to do a hardware kit I would buy one.

-

11-27-2014, 11:19 AM #8

Hi all, I can confirm that dual extruder is awesome. I only have one printer and I had to remove my existing extruder and steal a few screws so if this thing didn't work, I was out of a printer until I got things back together. But, that fear was unfounded because as soon as I began build it I realized it was going to work right away. I haven't looked back. I have about 15 hours of print time on it now without a single jam or hiccup. I had a power supply issue that stymied me a bit but I've worked past that I think. It had nothing to do with the extruder. The mods you need to make to Marlin are not difficult either. I can post what I did if people what that.

It's a great design, well thought out and great looking. So many extruder designs look like boxes glued to more boxes. This design really looks like it does what it says it does.

I appreciate the kudos for testing and feedback but I have to admit, it was so well designed that there was not that much to tweak. The fact that I was able to print it, order the parts and pretty much get it working on the first pass speaks volumes to the work that had already gone into the initial design and prototyping. I had to modify the design to fit my older style Makerfarm i3 8" as I have rods for the x-carriage. This was designed for the Markerfarm V-slot version, the latest model.

I made a special back plate for the extruder shelf and the only mod I needed for my Makerfarm was to drill two small holes in the wood of the x-carriage bearing plate. If there is interest I can upload that plate to Thingiverse for you. Those holes allow the extruder shelf to rotate enough to level the two hexagons. It's a really easy mod if you have the older Makerfarm, or, any other printer that has an "L" shaped mounting system.

So, go to Thingiverse and give this thing a try. It's worth the work. So, thanks 'clough42', for an awesome dual-extruder Hexagon solution for the Makerfarm.

DualHexagon_01.jpgDualHexagon_First-Print.jpgDualHexagon_Print_02.jpgBambu P1S/AMS

NVision4D http://nvision4d.com

-

11-28-2014, 04:40 PM #9Engineer

- Join Date

- Jul 2014

- Location

- Eastern Colorado

- Posts

- 536

Clough42, have you seen this? http://www.filastruder.com/products/...eid=a4395377f5 I hope it wouldn't be hard to get this hotend to work with your extruder, especially the Cyclops variant.

-

01-15-2015, 03:22 PM #10

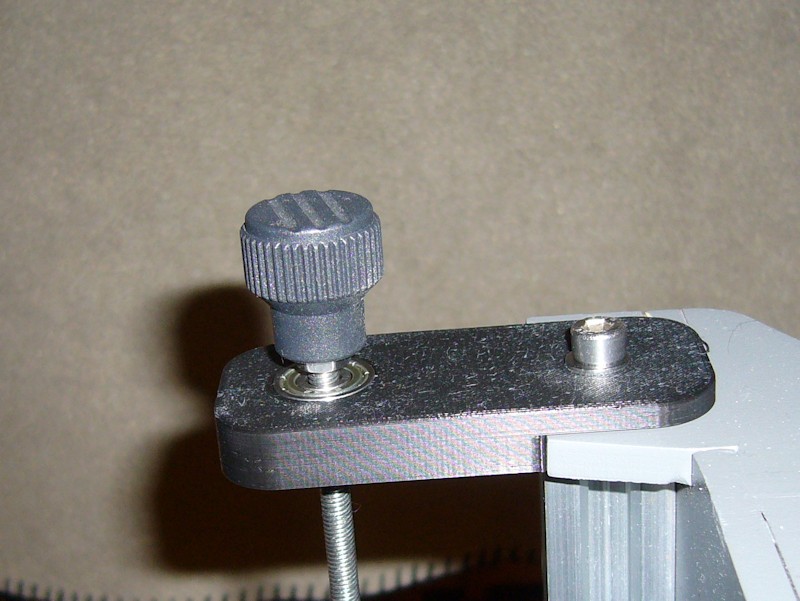

Z-ROD SUPPORT BRACKET

I've published an improved support bracket for use at the top of the i3v frames to Thingiverse - http://www.thingiverse.com/thing:636381. There's been another bracket out there, but I found ways to improve various aspects of it. Predefined STL files with and without a bearing recess are provided, along with the openSCAD source that allows the entire bracket to be customized.

The same bracket would be installed on both sides; I don't offer one that includes mounting provisions for the MakerFarm spool mount.

These won't improve print quality. In fact, if they're installed with pre-exisiting bent threaded rods, print quality might actually suffer since any bend may force the X carriage to wobble around a bit as the bent threaded rod is rotated. The brackets are intended to help prevent straight threaded rods from getting bent. In my case, I've been on borrowed time before our grand daughter grabbed one of the rods and bent it over.

Last edited by printbus; 05-29-2015 at 10:37 AM. Reason: migrated to offsite image storage due to 3DPrintBoard issues

Reply With Quote

Reply With Quote

Please explain to me how to...

Today, 03:08 PM in 3D Printer Parts, Filament & Materials