Results 1 to 10 of 174

Thread: My First CoreXY

Threaded View

-

10-20-2020, 08:53 PM #11

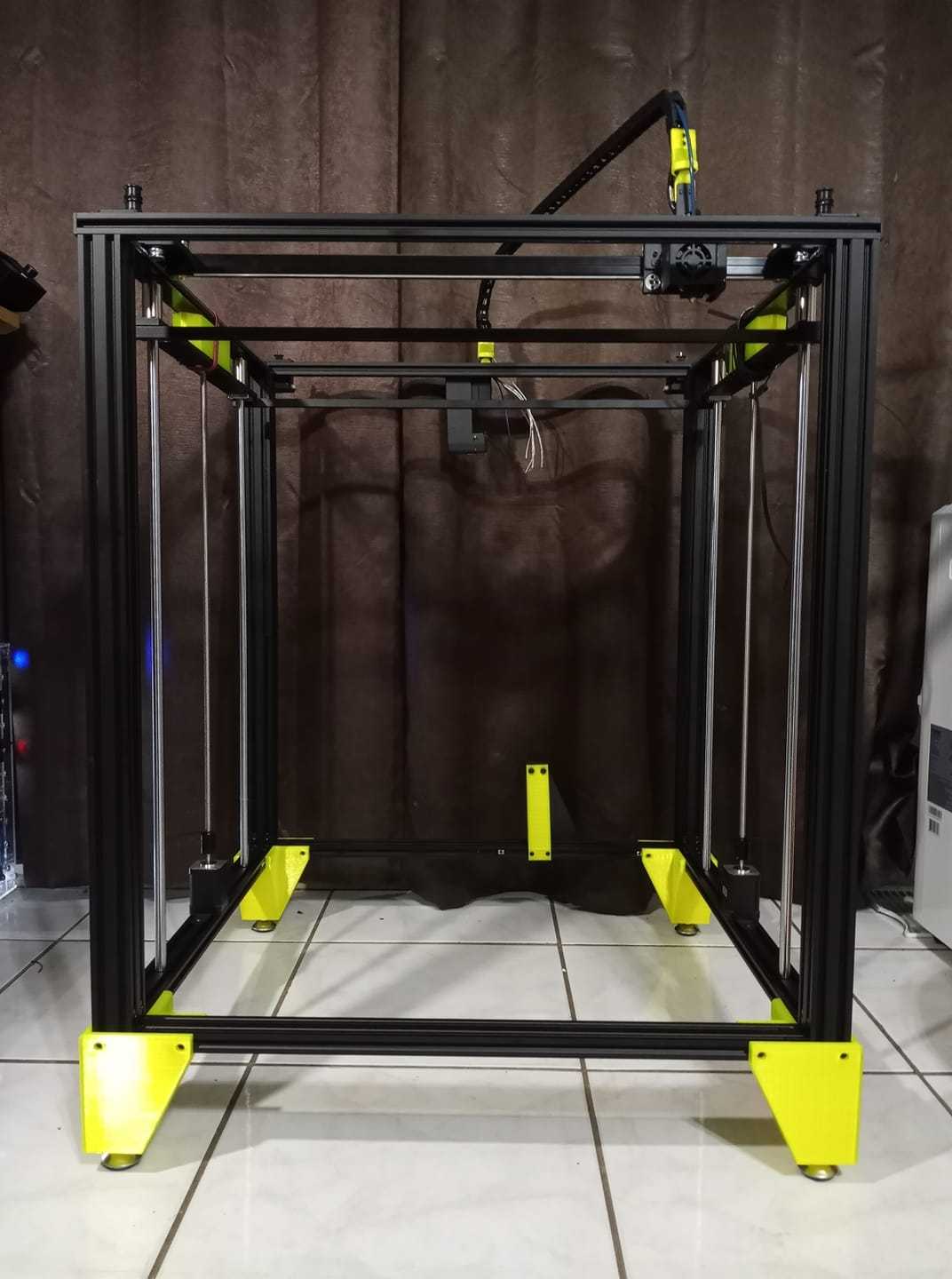

So because of the way the frame and X carriage and leadscrews are I had to make these yellow bricks so the Z carriage didn't flex and allow for extra steps from the Z steppers. When the carriage bottoms out the leadscrew needs to sop immediately. That is the yellow bricks on the carriage at the leadscrews. The yellow support at the lower rear of the frame is for the filament spool holder. It is just a plate and flexes easily so now it doesn't. There are a few spacers I made to go under the idler plates up top at the front of the machine and also to relocate the filament runout sensor so it is in line with the BondTech BMG extruder. The fewer wires inside the cable chain allowed me to put the Capricorn tubing inside the cable chain for an even cleaner look. And because the printer is so huge I am just gonna leave it on the floor so I drew up these feet that raise the printer 100mm, square the lower frame, and also moves the rubber feet out to the corners so the printer is even more stable. So far so good. The bed is off for it's mod..

Reply With Quote

Reply With Quote

Please explain to me how to...

Yesterday, 12:15 PM in 3D Printer Parts, Filament & Materials