Results 1 to 10 of 174

Thread: My First CoreXY

Hybrid View

-

05-25-2022, 09:06 PM #1

Well alright so my oversized coreXY build is done and it prints. I have printed a handful of things with it in PLA and PETG and I just know at some point here I will be happy with all this but for now we really need to do something about vibrations and inertia. The DD setup on the 500 Pro frame really wants to print super slow to get any kind of a decent print out of it.

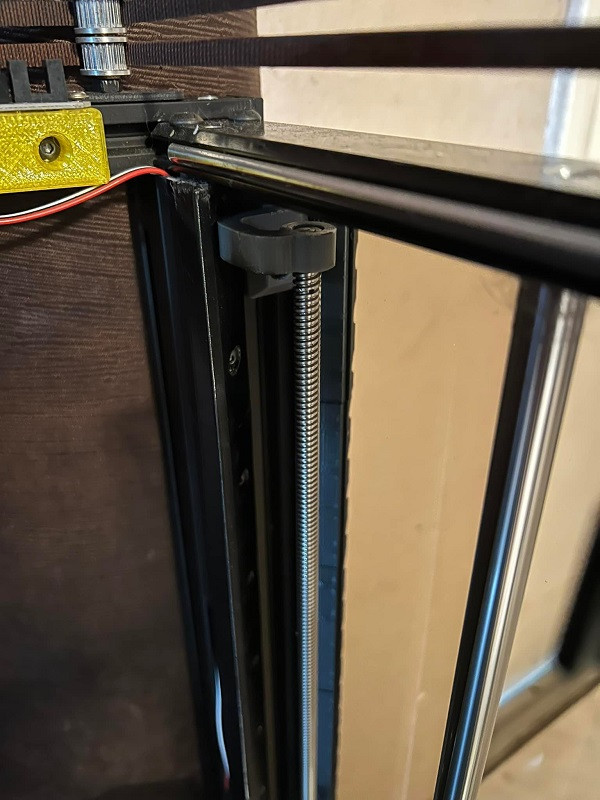

So the first thing I need to address is my 4 Z leadscrews. I left them open at the top and as the print grows the vibrations get worse from the increasing amount of unsupported leadscrew up top x4. So I made this simple part to hold the leadscrews. It uses a few pennies of the PETG, a single m4x10mm screw and m4 drop in T-slot nut. And it has a little deflection under light load so small amounts of runout on the leadscrew shouldn't impact the print quality..

Reply With Quote

Reply With Quote

Please explain to me how to...

05-17-2024, 12:15 PM in 3D Printer Parts, Filament & Materials