Results 1 to 10 of 51

Hybrid View

-

10-05-2019, 04:42 AM #1Technologist

- Join Date

- Jul 2017

- Posts

- 184

Box and V ways aren't wheels, and neither of them are extruded. They're usually cast iron and ground to shape. I'm positive you would have seen them on subtractive machines. Second picture down shows some V ways on a lathe bed: http://www.lathes.co.uk/okuma/

For the record, the two steppers I'm talking about is not two separate steppers, attached to two separate leadscrews. It's autowiz's idea of putting a stepper on either side of a closed loop of belt instead of having an idler at one end. Having two steppers on two separate leadscrews for Z is better than a cantilevered setup, but still not ideal. They can get out of sync, especially when power is off and the motors have no holding torque. Or if one motor skips steps etc it skews your X axis and you'll need to re-level it. ideally you'd couple the two leadscrews together so they stay in sync (say, with a belt) and drive the belt with a single motor. You can "fix" the issues by having two z homing switches, one for each motor, but most people don't. At that point it's just as easy to couple the two leadscrews and drive it all with one motor.

And autowiz. Just because you printed an i3 doesn't mean a thing. Lots of people have done it, and a lot of them just like you don't understand much if anything about design. Wiring two stepper motors together will not cause a house fire, I don't know what makes you think that, neither will a solenoid relay when used properly (you know a lot of your house appliances use them? Like ovens, boilers and more? Including resetable circuit breakers which help stop house fires?). What makes you think car parts are made to start house fires? Did your car burn down your apartment? You know the real fancy control boards like the rambo which have actual fuses for safety? Those are automotive fuses.

Also, steppers are not fancy servos. They're brushless motors "optimized" for holding torque and positioning accuracy and repeat ability with open loop control. Servos are the "fancy" ones with closed control loops and feedback. The pot on the driver board controls the current to the stepper, not it's initial position.

-

10-05-2019, 12:16 PM #2

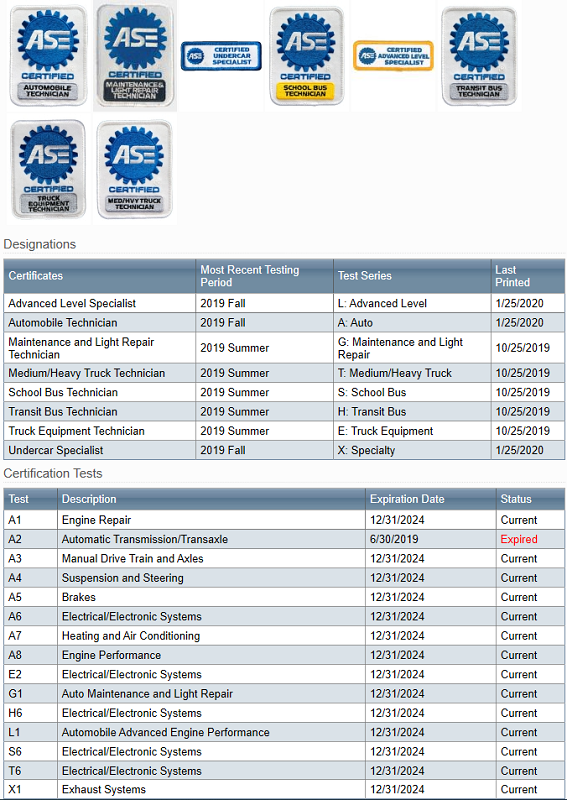

Well I understand cars and their parts better than you do. And let me start validating my claims right now. Here is my certification status from A.S.E.

Do you understand I re engineer American sports cars everyday and for a very pretty penny? For you to talk to me about design with these toys. What kind of God Damn fool are you, bro? To suggest car parts be used on 3d printers in a very dangerous way and then attack real skill when it comes in the room and corrects you? You have shown your intelligence. We get it. 2 digit I.Q. And nobody is gonna take that away from you buddy. In a world where everyone hunts down the best most specific parts available for what they are doing you are so successful in your life that you hunt down the cheapest and most deadly way of hacking something together. And then suggest others take these risks in the name of poverty as you did. My guess is you struggle financially from an overwhelming lack of success in your life, but, hey, I could be wrong. When someone asks for advice we should think of the best possible solution our minds can recall. For you to suggest these poor solutions to others shows how deep you are in your own design skills.

Do you understand I re engineer American sports cars everyday and for a very pretty penny? For you to talk to me about design with these toys. What kind of God Damn fool are you, bro? To suggest car parts be used on 3d printers in a very dangerous way and then attack real skill when it comes in the room and corrects you? You have shown your intelligence. We get it. 2 digit I.Q. And nobody is gonna take that away from you buddy. In a world where everyone hunts down the best most specific parts available for what they are doing you are so successful in your life that you hunt down the cheapest and most deadly way of hacking something together. And then suggest others take these risks in the name of poverty as you did. My guess is you struggle financially from an overwhelming lack of success in your life, but, hey, I could be wrong. When someone asks for advice we should think of the best possible solution our minds can recall. For you to suggest these poor solutions to others shows how deep you are in your own design skills.

-

10-05-2019, 12:33 PM #3

Just from right here on this very forum: https://3dprintboard.com/showthread....Mixing-Printer https://3dprintboard.com/showthread....twork-Printers https://3dprintboard.com/showthread....-250mm-X-300mm I think that accounts for a good amount of hands on experience right there. Aside from all that I do all day for an entire career on a much bigger scale than these tiny plastic toys. I like to play with the printers because I don't get dirty and I can stay in my home and it is clean and small work. Comparatively. And on the subject of experience I started this thread when I bought my first printer back in May of 2016: https://www.digitalcorvettes.com/for...d.php?t=269457

-

10-06-2019, 08:43 AM #4

It's just that I maintain 5 a.s.e. certifications just for electrical and electronic systems as I have shown. So I just can't let this fire hazard go. The ONLY way an IC can properly control a relay or solenoid or a coil of any sort is with what is called a 'coil driver circuit' which is like it's own little solid state relay of sorts or MOSFET that can handle switching very fast but MOST IMPORTANTLY it does not let the power or ground being applied to the coil touch the driver circuit because when switched off the KV spike from the collapsing field will destroy electronics and potentially set fires. But if we already have a MOSFET to control this relay or solenoid then why do we not just use that MOSFET to control the heater directly? I'm just speaking of 'proper use' of electronic devices and components as taught by a well funded education. What about you? Where did you not learn the correct way to use a solenoid or relay?

Last edited by AutoWiz; 10-06-2019 at 09:39 AM.

-

10-06-2019, 09:41 PM #5

And then there is this: https://www.superchargerforums.com/t...-machine.7445/

Reply With Quote

Reply With Quote

Ender 3 Neo - Jam Problem

05-08-2024, 03:06 PM in Tips, Tricks and Tech Help