Results 1 to 7 of 7

Thread: My first 3D printer

Hybrid View

-

10-15-2019, 04:42 PM #1

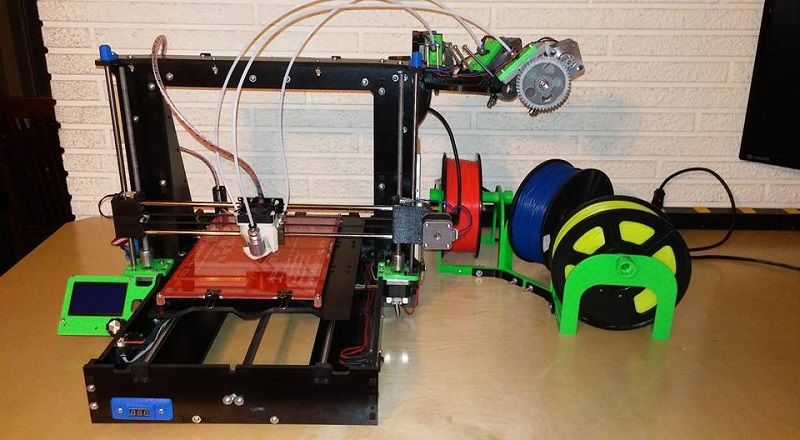

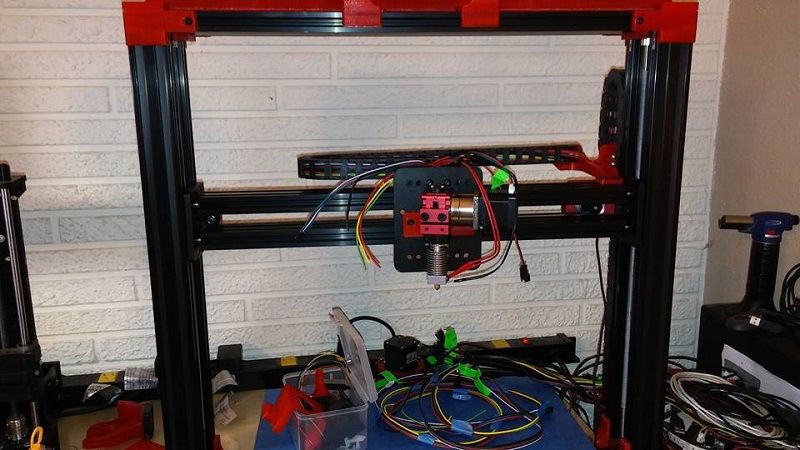

The MP mini builds a 120mm cube. This Prusa mini builds a 180mm cube. 20mm on each axis short of the 200mm cube that used to be the standard for 3d printers. small footprint but generous build envelope for its size. Also the 3:1 gear reduction ensures that the stepper motor is spinning faster at lower feedrates. Just like the Titan Aero. Do you remember the Gregg Wade extruders? I used 3 of them for my mixing printer years back..

That was a 10.43:1 ratio. And then my Tevo Black Widow printer came with this extruder that had 5:1 reduction..

That was a 10.43:1 ratio. And then my Tevo Black Widow printer came with this extruder that had 5:1 reduction..  I switched it to a Titan Aero for that 3:1 but I think that is the gold standard for the average E. 3:1 puts the steps per MM into such a happy place the motor has gobs more torque, it spins smoother, and there is the most precise control without overloading the processor with crazy math from 5,000 steps/mm of travel.

I switched it to a Titan Aero for that 3:1 but I think that is the gold standard for the average E. 3:1 puts the steps per MM into such a happy place the motor has gobs more torque, it spins smoother, and there is the most precise control without overloading the processor with crazy math from 5,000 steps/mm of travel.

Last edited by AutoWiz; 10-15-2019 at 04:53 PM.

Reply With Quote

Reply With Quote

Please explain to me how to...

Yesterday, 02:43 PM in 3D Printer Parts, Filament & Materials