Results 151 to 160 of 255

Hybrid View

-

01-15-2015, 03:11 PM #1

Printing speeds are also pretty tough to compare. A set speed can't be met unless both Marlin and the slicer are configured for it or the slowest setting will dominate. Set speeds may not be realized if the slicer is configured for print thermal management that slows things down to maintain a minimum layer time. Even when high print speeds are observed in a viewer like gcode.ws, they may not be realized if a lot of the printed movement is spent in acceleration and deceleration. So, without knowing the overall context, hearing about someone's print speed may not mean much.

Being a month in, you're likely still fascinated by the printing process. Nothing wrong with that. I got to the point where printing started to get kind of boring, and I began wondering whether prints had to be going as slow as they were.

-

01-15-2015, 06:05 PM #2Engineer

- Join Date

- Nov 2014

- Posts

- 522

-

01-18-2015, 09:13 PM #3Engineer

- Join Date

- Jul 2014

- Location

- Eastern Colorado

- Posts

- 536

I have to replace my Z threaded rods too. The one on the RAMPS side is worn out from ABL raising and lowering over the same area repeatedly. It's so bad I can't print anymore, that Z nut keeps slipping down over the worn area. Thanks guys for the Grainger part numbers, that made it easier to find replacements.

edit: Though it occurs to me now after I've placed the order, that I could just flip the rods over so that the worn area is higher up, where it won't interfere with shorter prints. >_

-

01-31-2015, 07:21 PM #4

Nice work. Hmmm, now you have me thinking about modding again.

Bambu P1S/AMS

NVision4D http://nvision4d.com

-

02-02-2015, 11:17 AM #5Student

- Join Date

- Jan 2015

- Location

- Minnesota

- Posts

- 5

This is a wonderful read for me, I've looked at a number of printers, and I'm intrigued by the prusa I3v line, I'm pretty well set on a 10/12" model. At this point, I haven't ruled out more expensive printers, but like the idea of building it myself to get a feel for the printer, as well as its community base.

I've been considering adding a few components to the assembly out of the box so I can do it on first assembly rather than later, though indubitably I will have to do this in the future, anyway. I was considering the kysan motors as one such addition. Do you have any recommendations on parts to add to the initial build either due to increased quality, or difficulty in adding them at a later time?

I've already got an area set aside, and plan on making an enclosure and filament storage container for the printer.

-

02-02-2015, 11:51 AM #6

Glad these threads are helping. You might also want to have a look at this thread I started a few months ago:

http://3dprintboard.com/showthread.p...Show-your-MODSBambu P1S/AMS

NVision4D http://nvision4d.com

-

02-02-2015, 11:23 AM #7

Msmnick, check out this thread, some of the same questions about upgrades have been posted and answered . http://3dprintboard.com/showthread.p...rinter-Ordered.

Where in MN are you? I just moved to OK this summer from the cites.

-

02-02-2015, 11:53 AM #8

Thanks for jumping in, Todd. Thanks to Rob as well for the response that came in while I was editing.

Thanks for the feedback. I don't regret my MakerFarm choice a bit. It's a great way to go, especially as a learning experience. The community here is top notch. Along with superb customer support from MakerFarm, the level of support is hard to beat.

Msmnick, I tend to avoid that question. Not everyone has the same expectations for their printer or print results. Everyone has a different level of fortitude, time and budget they're willing to throw at their 3D printer. I also think it can be beneficial to start with the basics and enhance the printer as experience grows or as issues come up. If you were building the 8-inch, I'd highly suggest doing something different for the lacking Z-endstop switch mount - I'll offer that much. Feel free to PM me or visit with whoever is around on the Makerfarm IRC chat if you want to discuss thoughts on specific mods.I've been considering adding a few components to the assembly out of the box so I can do it on first assembly rather than later, though indubitably I will have to do this in the future, anyway. I was considering the kysan motors as one such addition. Do you have any recommendations on parts to add to the initial build either due to increased quality, or difficulty in adding them at a later time?

On the Kysans, I can't say that they are a value added benefit on the newer kits. Older kits shipped with a different motor that didn't really fit the 12V printer application very well, with an issue that they ran extremely hot. That's the main reason why mine were replaced. Newer kits ship with more appropriate motors that don't run hot.Last edited by printbus; 02-02-2015 at 05:07 PM.

-

02-22-2015, 04:11 PM #9

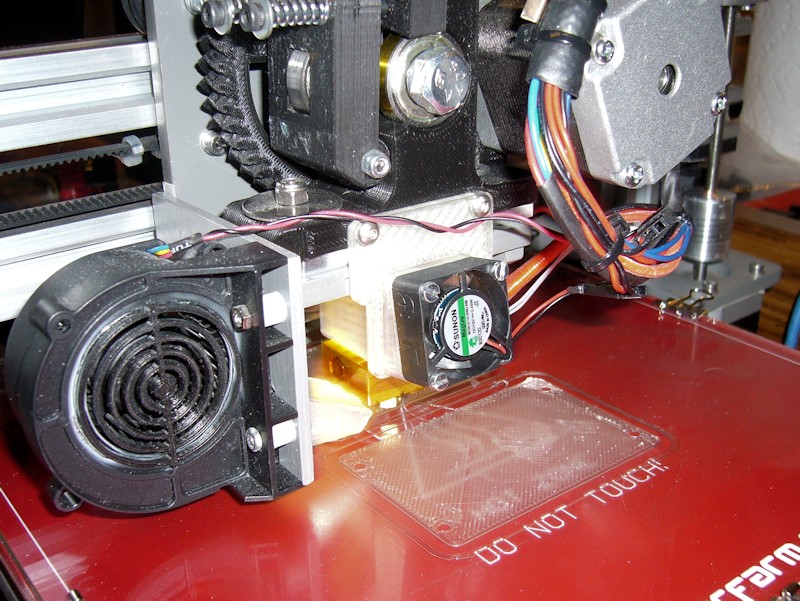

NEW APPROACH FOR THE HEXAGON HOT END SHROUD

Finally came up with my own shroud design for the hexagon hot end that should do a better cooling job than the stock shroud, and shouldn't have a tendency to melt and drip onto the print bed or a print. See http://www.thingiverse.com/thing:693913 for STL files. Two styles are provided - both use a 25mm fan like the 3CFM Sunon MAGlev MC25101V2-000U-A99 fan. One style mounts the fan flush to the shroud, and the other style angles the fan exhaust upwards by 10 degrees to clear the heated bed area.

Last edited by printbus; 05-03-2015 at 04:19 PM. Reason: migrated to offsite image storage due to 3DPrintBoard issues

-

02-02-2015, 12:22 PM #10Student

- Join Date

- Jan 2015

- Location

- Minnesota

- Posts

- 5

Well, that's info worth knowing. Thank you. I didn't know they changed the motor offering, though one can see why if they were having heat issues. I'll find out if the Z-endstop is built similar to yours on the model I select. Noted the addition of a screw adjustable endstop as a mentioned solution, seems like an easy way to avoid that hassle. I will look at the kysans again with what comes with my model and likely scratch them off the list. Like most people here, I have some fabrication/mechanics/electronics/engineering background, I was an electronics tech in the Navy, go to school for Mechanical Engineering, and work as a mechanic. The 3d print/cad stuff is a hobby currently, so budget is mediocre. I was considering a few nice models 2-3x the cost of this, fully assembled/fully enclosed, but the experience of these models has me intrigued, and I don't see the others offering better specs, better support, more/cheaper filament, etc.

I'm in the Moorhead area, I venture out the the Twin cities from time to time. Currently traveling south to avoid February in Minnesota.

Reply With Quote

Reply With Quote

Please explain to me how to...

05-17-2024, 12:15 PM in 3D Printer Parts, Filament & Materials